Fd3a service and troubleshooting, Fan motor, Li. electric heater service – Bryant FA4A User Manual

Page 21: A. limit switch, D. fan beley, E, heater removal, Fd3a service and troubleshooting -23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

A U G / 1 4 / 2 0 0 8 / T H U 0 3 : 5 0

UTC TECH PUB

ni

N o , 3 1 7 2 4 0 5 6 6 2

P . 0 2 1

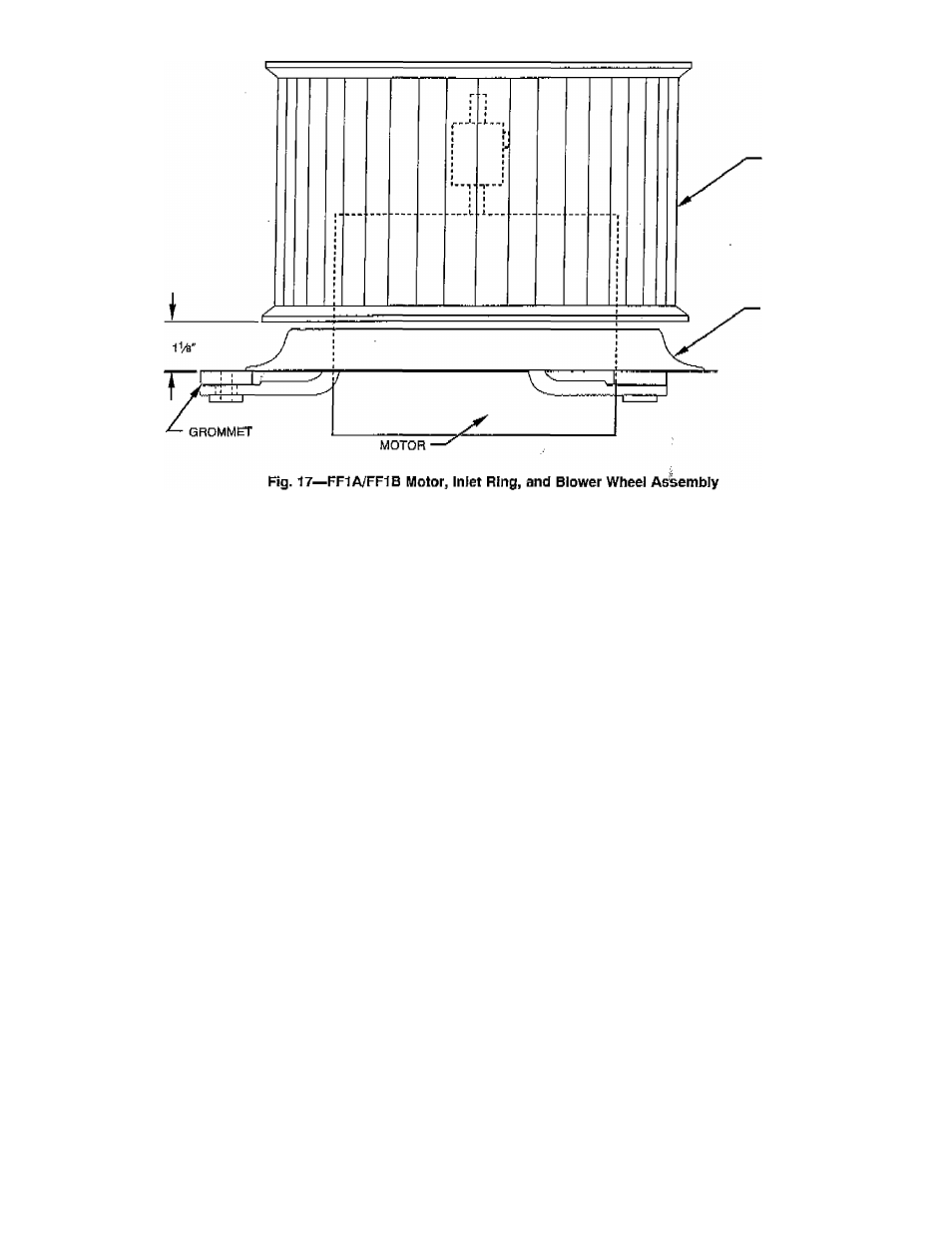

BLOWER

WHEEL

INLET

RING

FD3A SERVICE AND TROUBLESHOOTING

WARNING: Btfom instaJlation or servicing system,

always turn off main powet to system. There may be

more than 1 disconnect switch/Turn off accessory beater

power if applicable. Electrical shock can cause personal

injury or death.

1. FAN MOTOR

The motor is 2-spccd direct drjve. High-speed lead is black,

low-speed lead is red, and common lead is yellow,

NOTE: Unused fan speed leads must be tapped off to prevent

direct short to cabinet surface.

The motor is turned on through 2 different routes. The first occurs

when thermostat calls for the fan in cooling, heat pump, or

fan-only mode. A

24’Vac

signal is sent to relay, causing relay to

close its normally-open contacts, turning fan on. The second

occurs when there is a call for electric heat. A 24-vac signal is sent

to heater sequencer, causing it to close, directing 230v through the

normally-closed contact of fan relay, turning fan on- The fan

remains on until sequencer opens. Refer to FD3A typical wiring

diagram shown in Fig. 18.

li. ELECTRIC HEATER SERVICE

Service can be completed with heater in place. Shut off power

before servidng-

A. Limit Switch

Malfunction prevents heating element from coming on. Replace

switch if malfunction occurs,

B.

Sequencer

Malfunction causes heater not to come on or never shut off.

Replace sequencer.

C.

Transformer

A 60-va transformer supplies 24-v power for control circuit.

Replace transformer if faulty.

NOTE:

Transformer is fused. Do not short

circuit.

AÔËÛOS

D. Fan Beley

Malfunction causes unit fan not to run or run continuously.

Replace relay.

E, Heater Removal

Disconnect wiring, remove 2 sheet metal screws, and pull heater

out through

Open

hinged access panel. When replacing heater,

ensure orientation of he&ter element is same as when removed.

ML

cleaning

OB REPLACING REFRIGERANT FLOW-

CONTROL DEVICE

1. Pump down outdoor unit. Close service valves at outdoor

unit.

CAUTION:

Damage may occur to the scroll compressor

if operated at a negative suction pressure during a system

pumpdown.

2. Bleed and (if possible) recover remaining refrigerant from

tubing and coil through gage port on vapor-tube service

valve.

3. Disconnect liquid refrigerant tube from refrigerant flow-

control device. Refer to Fig, 19,

4.

Remove refrígerapt flow-control device piston retainer.

Avoid damaging 6-xing or machined surfaces on piston,

bore, and retainer,

5. Using small wire with a hook on end of it,

remove

piston

from refrigerant flow-control device body.

A

CAUTION: When cleaning piston orifice, be careful not

to scratch or enlarge opening as this will affect operation.

-21-