C. if pcb fuse keeps blowing, Vi. troubleshooting icm2 fan motor, A. if motor does not run – Bryant FA4A User Manual

Page 13: B. if motor does not run smoothly, C. if motor shaft does not rotate smoothly

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

AUG/14/2008/THU 03:48 PM UTC TECH PUB

FAX No. 317 240 5662

P. 013

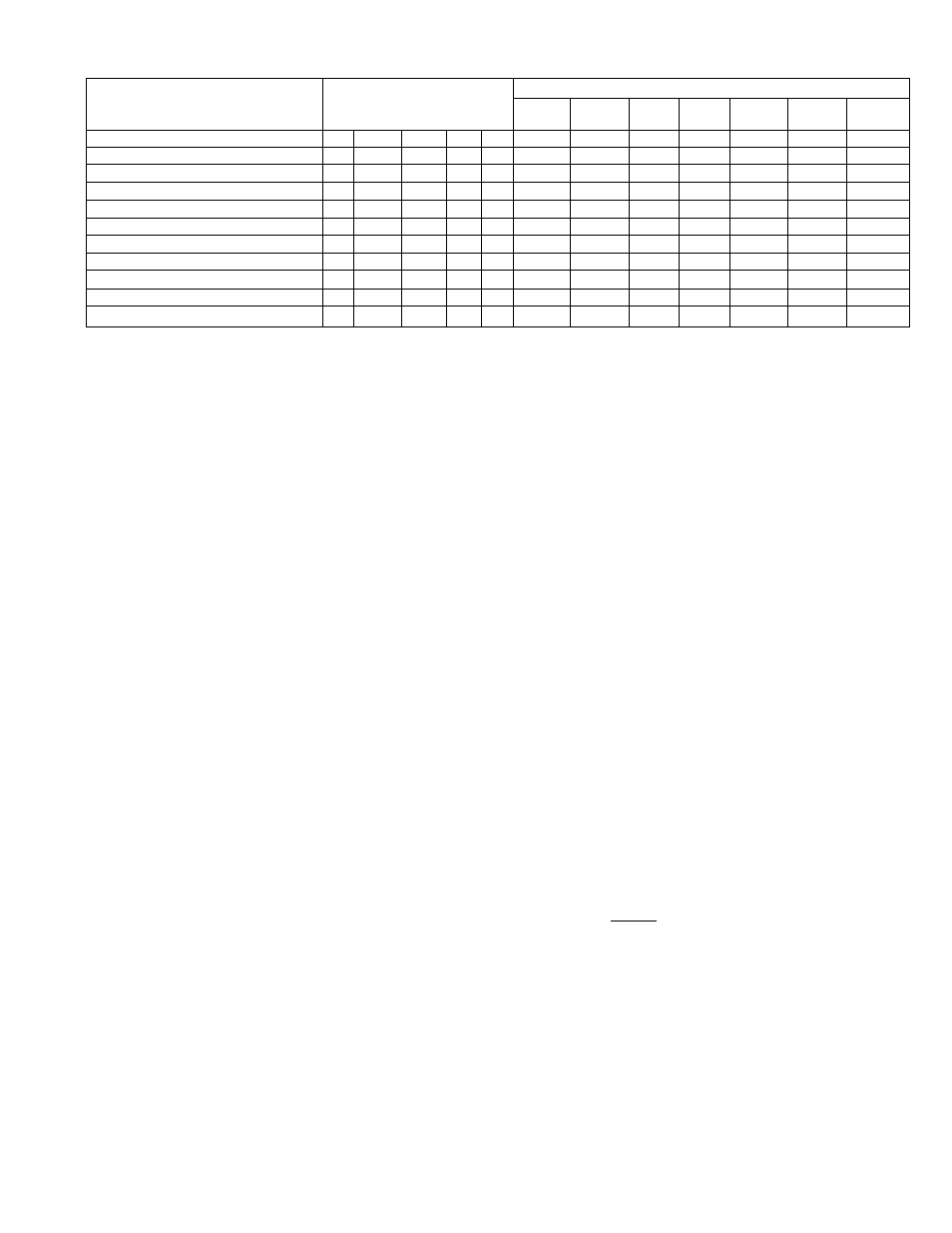

TABLE e—МОТОВ CONTROL TEST VALUES

OPERATING MODE

SCREW TERMINALS

HAVING 24 VAC

VOLTAGES—7-PIN PLUG P2

W

Pin 1

Q

Pin 2

C

Pln3

c

Pin 4

R

Pin 5

Y/Y2

Pin 6

Y

Pin 7

Electric

Heating

R

W2

W3*

E*

24 vde

0

0

0

£4 vac

0

1-Speed A/C

Cooling

R

Y/Y2

G

0

£4 vac ,

0

0

24 vec

24 vac

0

2-Speed A/C, Low Speed

Cooling

R

Y1

Q

0

£4 vac

0

0

24 vac

0

24 vac

S-Speed A/C, High Speed

Cooling

R

Y/Y2

G

0

24 vac

0

0

24 vac

24 vac

0

1-Speed HP

Cooling

R

Y/Y2

G

0

□

£4 vac

□

0

£4 vac

24 vac

d

1-Speed HP

Heating

R

Y/Y2

G

0

24 vac

0

0

24 vac

24 vac

0

2-Speed HP, Lew Speed

Cooling

R

Y1

G

0

0

£4 vac

0

0

24 vac

0

24 vac

2-5peed HP, Low Speed

Heating

R

Yi

G

0

24 vac

0

0

£4 vac

0

24 vac

2-Speed HP, High Speed

Cooling

R

Y/Y2

Y1

G

0

0

24 vac

0

0

24 vac

24 vac

24 vac

2-Speed HP, High Speed

Heating

R

Y/Y2

YI

Q

0

24 vac

□

0

24 vac

24 vac

24 vac

ContinuDue Fan

R

0

24 vac

0

0

24 vac

Q

0

Pin 1 @ 24 vdc with or without jumpers when ever any Individual heeter input or any combination of heater inputs are energized.

C.

If PCB Fuse Keeps Blowing:

When low-voltage fuse blows, it means transformer would have

blown if fuse had not been in circuit to protect it. The fuse usually

blows when there is a high current drawn on transformer, high

voltage applied to low-voltage circuit, or a direct secondary short.

When there is a high current drawn on fransforaier, it is most likely

because transformer has been shorted or system is trying to draw

more va than transformer rating allows. When fuse blows because

of high voltage, the system has mixed high- and levy-voltage

signals,

1. Check transformer and thermostat wiring. (See Fig. 6 and

8,) Be Sure transformer is not shorting out because thermo

stat wires are miswired,

2. Check wiring of sequencers. (See Fig. 6 and 8,) Be sure

low-voltage and high-voltage wiring are connected to

proper sequencers.

3. Check va draw o.n transformer. If va draw is more than va

rating of transformer, fuse will blow. If this is the case,

replace transformer with one that has a higher va rating and

meets system specifications,

VI.

TROUBLESHOOTING ICM2 FAN MOTOR

A.

If Motor Does Not Run:

1. With power turned off, check all plugs and receptacles on

circuit board and at motor for any defonnation that may

cause a bad connection. Be sure all plugs are placed fully

seated.

%. Verify that there are approximately 230v at terminals Ml

apd Iyf2.,lf not, determine if high voltage is entering board.

It enters through black and yellow wires at pins 7 and ? in

12-pin plug.

3, Verify that there is a low-voltage control signal to motor.

The motor receives its contml signals through the 7-pin

mQ,tor plug P2. The voltage output of each pin in plug will

be different for each mode of operation. Table 6 lists circuit

board screw terminals that have 24 vac present (powered by

thermostat) and lists voltage that is present at each pin of

7-pin plug for each operating mode. Tests should be taken

between points listed and common (C screw terminal). If all

values of any 1 of operating modes checks OK and motor

fails to run, then motor is defective and should be replaced,

B.

If Motor Does Not Run Smoothly;

First verify that the cause is not an out-of-balapce or damaged

blower wheel. If it is not blower wheel, motor is defective and

should be replaced.

C. If Motor Shaft Does Not Rotate Smoothly:

When manually turning

Shaft

Of ICM, the shaft does not rotate

smoothly. The shaft has steps during rotation and is referred to as

motor cogging. The cogging is caused, by permanent

magnets

passing each pole of motor. However, shaft should not require

excessive force to turn. If shaft is VERY difficult to turn, motor

control or bearings have failed and motor must be replaced.

D. If Motor Does Not Stop Running

1. Check for good ground between motor ground lead and

transformer common lead.

2. If motor continues to nin, remove all thermostat wires. If

motor stops, replace circuit board.

3. If motor continues to run,

remove

the 7-pin plug. If motor

continues to run, replace motor.

VII.

CONDENSED VERSION OF TROUBLESHOOTING

FK4B MOTOR AND CONTROLS

This section provides a quick summary of how to troubleshoot the

FK4B. If more information is needed, refer to appropriate sections

of this service manual.

+ MOTOR

- If motor is hard to turn manually, replace motor.

- If motor docs not. run, check the components listed below

according to their instructions.

■- If motor runs in some operation modes and not in others,

check for a good ground connection between motor ground

lead and circuit board screw marked "ground screw" and

check the room thermostat and wiring harness according to

instructions listed

below.

- If motor does not stop running, remove the 7-pin plug from

circuit board. If motor continues to run, replace motor. If

motor stops running,''it is either the circuit board or thermo

stat causing the problem. Test whether thermostat is at fault

by disconnecting it from the board.

+ CIRCUIT BOARD

- Check 5-amp fuse,

- Check for 230v between terminals Ml and M2. If m voltage

is present, check power to'board. 230-v power enters the

board through the black and yellow lead in the 12-pin plug,

- Check for 24v between SECl and'SEC2, If no voltage is

present, check the transformer.

- Check for burn traces or burnt components. If bum spots arc

present, replace board.

'13-