Lubrication, Recommended accessories – Sears 113.241591 User Manual

Page 39

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

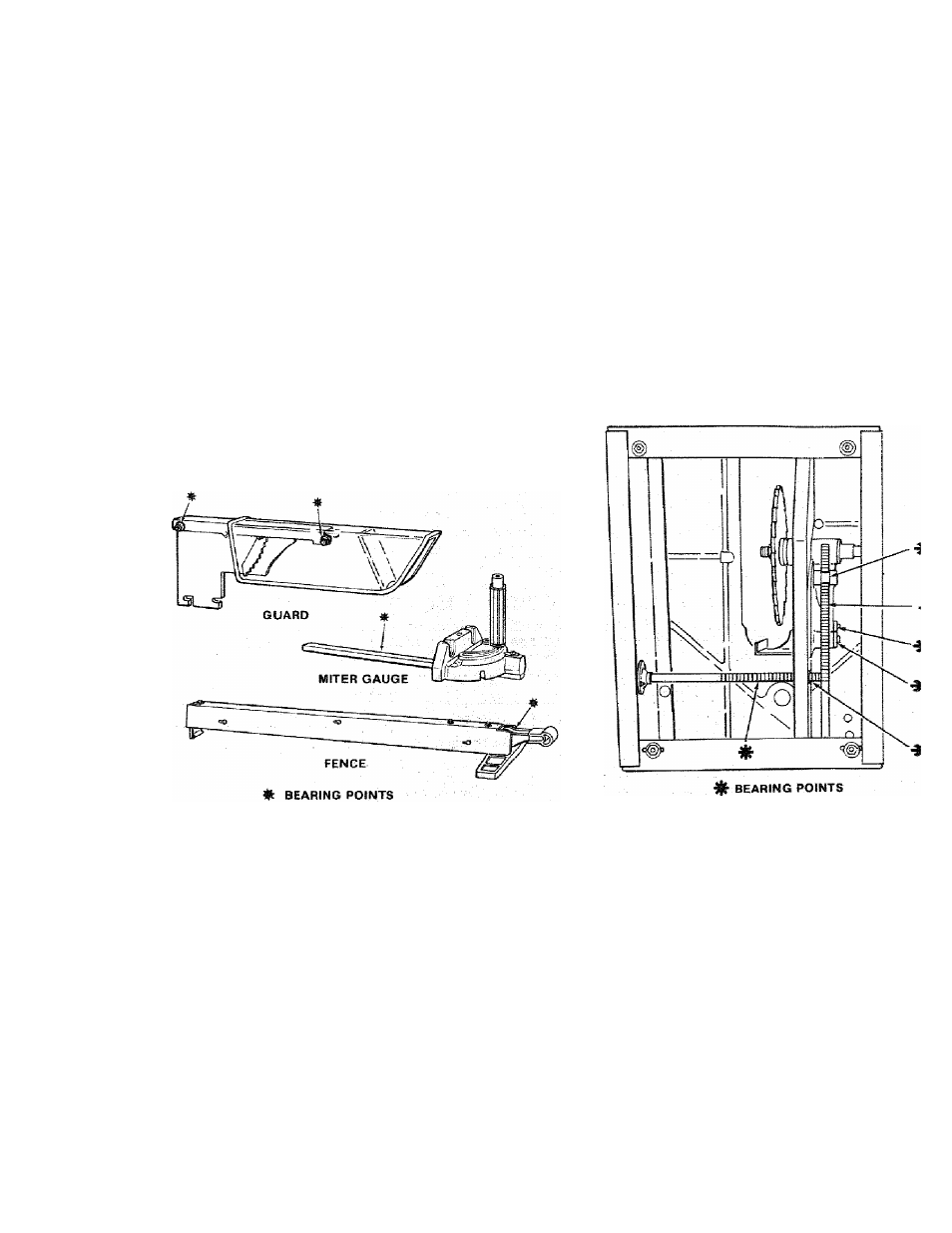

LUBRICATION

The following parts should be oiled occasionally

with SAE No. 20 or No. 30 engine oil.

1. Tilt screw threads and pivot nut. (First Clean with

Craftsman Gum & Pitch Remover.)

2 Elevation screw threads and pivot nut. {First

Clean with Craftsman Gum & Pitch Remover.)

3. Cradle bearing points.

4. Bearing points in guard assembly, miter gauge

and rip fence.

LUBRICATION OF FLEXIBLE SHAFT

Flexible shafts do require periodic lubrication

because the core acts as a screw conveyor which

will pump the lubrication to one end of the shaft over

an extended period of operation. The frequency of

lubrication depends on how the saw is used. When

the saw operates continuously for long periods of

time, a lubrication schedule should be developed.

The time period may be every 80 or 100 hours. An

indication that the shaft needs lubrication is when it

becomes noisy. Conversely, when the saw has

limited and infrequent use, the grease will

eventually age and harden so that it will notprovii

an adequate oil film between the core and casi r

liner and must be replaced.

LUBRICATION PROCEDURES

1. Remove the core from the casing, clean the co

■

■ ■

'

approvre

by washing

solvent.

with kerosene or an

4.

2. Dry the core.

3. Inspect the core for worn or broken wires. If co

is damaged, it should be replaced.

“Butter” the entire length of the core with a go <

grade of general purpose bearing grease witin

minimum operating temperature of -40“F ai

reassemble in casing. DO NOT force the great

into the casing with a grease gun. Too mu'

grease will affect shaft life because it makes î

core work harder.

RECOMMENDED ACCESSORIES

ITEM

Steel Stand ....................... .

Caster Sets . . . . . . . . . . . .

Solid Table Extension ..

7 In. Molding Head Set .

7 In. Molding Head Set

7 In. Molding Head-----------

Molding/Dado Insert for 7 in.

Dia. Molding or Dado Head.......................... 9-22271

Work Light ........................................................... 9-2480

Sawdust Collection

System ....................... 9-24242

10" Dia. Sawblades with 5/8" Bor© . See Catalog

Work Light .......................................................... 9-2481

CAT. NO.

................... 9-22214

9-22222 or 9-22221

................... 9-29957

...................... 9-3217

...................... 9-3218

...................... 9-3214

ITEM

7

In. Dia. Adjustable Dado Head

, T .

. . . . .■ 9-3261

7

In. Dia. Dado Head —................... .......

Sanding Wheel .................................

Miter-Gauge Stop Rods . . . . . . . . . . .

Miter-Gauge Hold-Down Clamp . -.

Taper Jig .................. .. ......................

Universal Jig -------- --. . . . ■ •

Powe Tool Know How Handbook

Table Saw ... ... .........

Cast

Iron

Extension, 12 X 27 Inches

Rip Fence Bar

' • • ■

Table Extension Kit . . . .

CAT. N

- 9-3262 - 9-3П

. 9-3Н

9-221

9-29€

9-29S

,. -9-3Î

. 9 - 3 i

■. .9-2Н

9-22Н

9-291

■9-29Н

39