Mounting the flexible shaft, Mounting the flexible, Shaft – Sears 113.241591 User Manual

Page 15

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

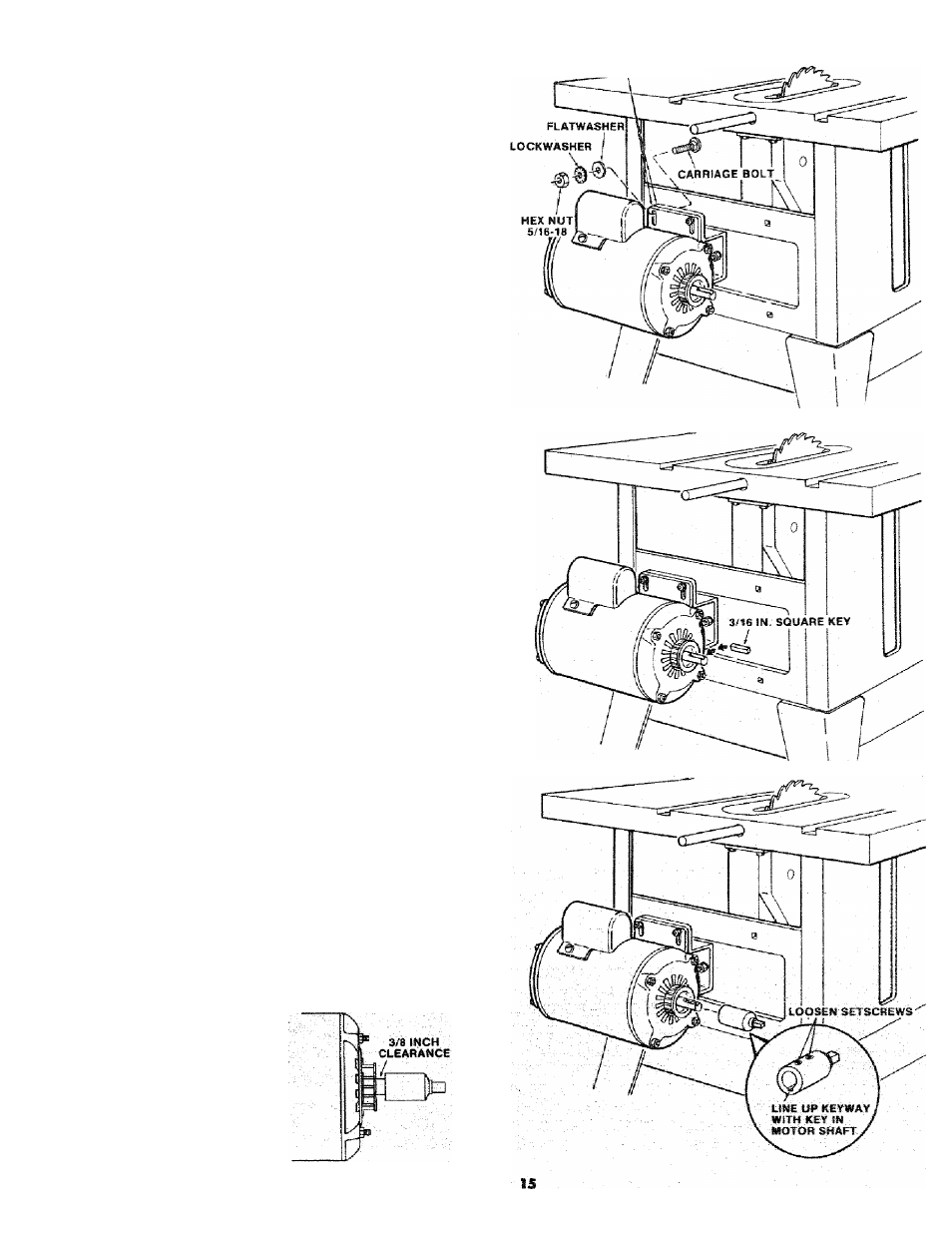

THESE TWO EDGES EVEN

5. From among the loose parts, find the following

hardware:

4 Carriage Bolts, 5/16 - 18 x 3/4 in. long

4 Flatwashers 17/64 x 3/4 x 1/16

4 Hex. Nuts. 5/16 - 18 (approx, dia, of hole 5/16

in.)

4 Lockwashers, 5/16 in. External Type

(approx, dia. of hole 5/16 in.)

6. Place motor on MOTOR MOUNT . .. insert bolts

through holes in MOUNT then through the motor.

Install lockwashers, and hex. nuts. Do not

tighten,

7. Position MOTOR BASE on MOTOR MOUNT so

the edges of the MOTOR BASE and the MOTOR

MOUNT are even. Tighten all 4 Hex. nuts

securely.

MOUNTING THE FLEXIBLE SHAFT

1. From among the loose parts find the following:

3 Pan Head Screws 8-32 x 3/8 in. long

3 Lockwashers External Type No. 8

2 Carriage Bolts 1/4 - 20 X 3/4 in. long

2 Hex Head Screws 1/4-20 x 1 in. long

4 Hex Nuts 1/4-20 (approx, dia. of hole 1/4 in.)

2 Washers 17/64 x 3/4 x 1/16

4 Lockwashers External Type 1/4 in. (approx,

dia. of hole 1/4 in.)

2 Shaft Brackets

1

Flexible Shaft Assembly

1 Motor Connector

1 Square Key 3/16 x 5/8 long

2. install 3/16 in, square key in motor shaft keyway.

3

Loosen the 2 setscrews in the MOTOR

CONNECTOR. Line up the keyway in MOTOR

CONNECTOR with the 3/16 in. square key on

the motor shaft.

4. Slide the MOTOR CONNECTOR ontothe motor

shaft as far as it wilt go. SECURELY tighten 2

setscrews. Test setscrews by trying to slide

motor connector off motor shaft.

IMPORTANT:

Make

sure

the

MOTOR

CONNECTOR is pushed on the shaft as far as it

will go, (Approx. 3/8 inch from motor end

shield.) .....