Repair & adjustments – Sears 917.25446 User Manual

Page 20

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

REPAIR & ADJUSTMENTS

A

LEAD-ACID

BATTERIES

GENERATE

EXPLOSIVE GASES. KEEP SPARKS,

FLAME

AND

SMOKING

MATERIALS

AWAY

FROM

BATTERIES.

ALWAYS

WEAR

EYE

PROTECTION

WHEN

AROUND BATTERIES.

IDLE FUEL

CASING

STOP

1, Starling your Tractor With a Weak Battery

If your battery is too weak to start the engine, it should be

recharged. If "jumper cables" are used for emergency

starting, follow this procedure:

NOTE: YOUR TRACTOR iS EQUIPPED WITH A 1 2 VOLT

NEGATIVE GROUNDED SYSTEM, THE OTHER VEHICLE

MUST ALSO BE A 12 VOLT NEGATIVE GROUNDED

SYSTEM

a .

Connect each end of the

RED

jumper cable to the

POSmVE(+) terminals of each battery (taking care

not to short against chassis) . (Fig. 28)

b Connect one end of the BLACK jumper cable to the

NEGATIVE (-) terminal of fully charged battery.

c Connect the other end of the BL A CK jumper cable

to the L.H. side panel boll (Fig. 14) NOTE: KEEP

AWAY FROM GAS TANK AND BATTERY

d Disconnect cablesrin reverse order:

1 L..H. side panel bolt (Fig. 14)

2

Negative terminal of fully charged battery

3

Positive terminals

DO NOT USE YOUR TRACTOR BAT

TERY TO START OTHER VEHICLES

2

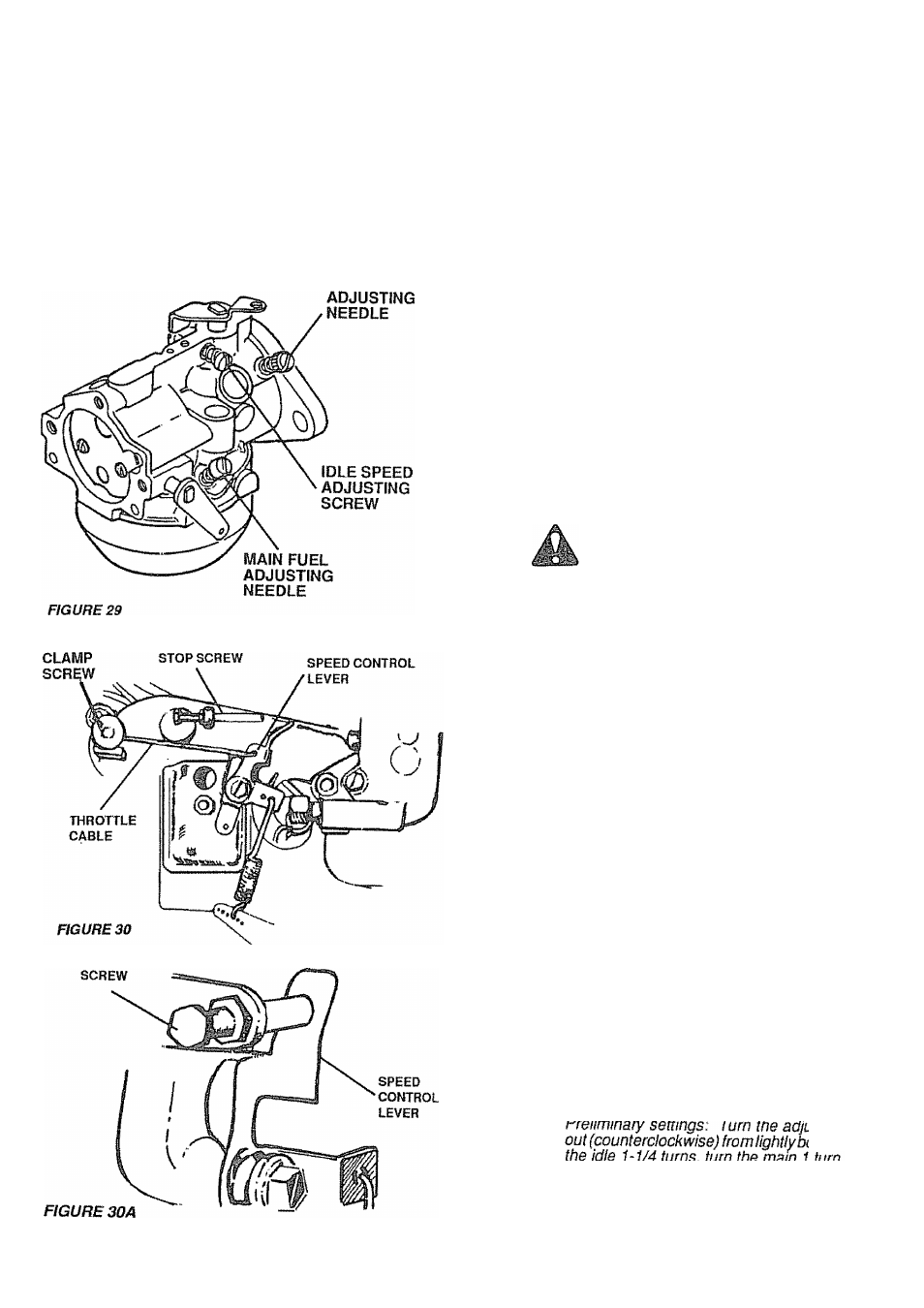

Throttle Control Cable Adjustment

Never attempt to change maximum engine speed

This is preset at the factory (3600 rpm± 75 rpm) and

should only be changed by a qualified service techni

cian who has the necessary equipment

a. Remove hood (Fig. 32).

b. Loosen casing clamp screw (Fig. 30) until throttle

cable is free to move.

Move throttle control (on dashboard) to "FAST"

position.

Pull throttle cable tight (until speed control lever

(Fig. 30A) is against stop screw (Fig.. 30A). Re-

tignten casing clamp screw.

c.

d

A

REFER TO

PAGE 12

-STARTING THE ENGINE

a.

20

3

Carburetor Adjustment

In general, turning the adjusting needles (Fig. 29) in (clock

wise) decreases the supply of fuel to the carburetor. This

gives a leaner fuel/air mixture. Turning the adjusting

needles (Fig. 29) out (counterclockwise) increases the

supply of fuel to the carburetor. This gives a richer fuel/air

mixture. Setting the needles midway between the lean and

rich positions will usually give the best results.

Adjust the carburetor as follows:

With the engine stopped, turn the idle fuel adjust

ing needle in (clockwise) until it bottoms lightly.

NOTE: The tip of the idle fuel and main fuel

adjusting needles are tapered to critical dimen

sions. Damage to the needles and the seats in

carburetor body will result if the needles are forced.

”

"

......

' ¡sting needles

Jttomed.. Turn

d

Start the engine and run at half throttle for five to ten

minutes to warm up. The engine must be warm

before making final settings (Steps d, e, f, andg).

Place the throttle into the 'fast" position.