Maintenance, Every wo hours – Sears 917.25446 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

Ain SCREEN

HOSE

C L A M P

5,

Lubricate Steering and Front Wheels

There is a grease fitting on each front wheel and axle spindle.

Use a grease gun to give each grease fitting two shots of

extreme pressure lubricating grease (available through your

Sears Service Center)(Fig 241

6. Oil Pivot Points

Place several drops ofSAE 30 oil at points where metal parts

move against each other, especially:

a.

Hood hinges

b. Shifter shaft points,

SEE LUBRICATION CHART. PAGE 19

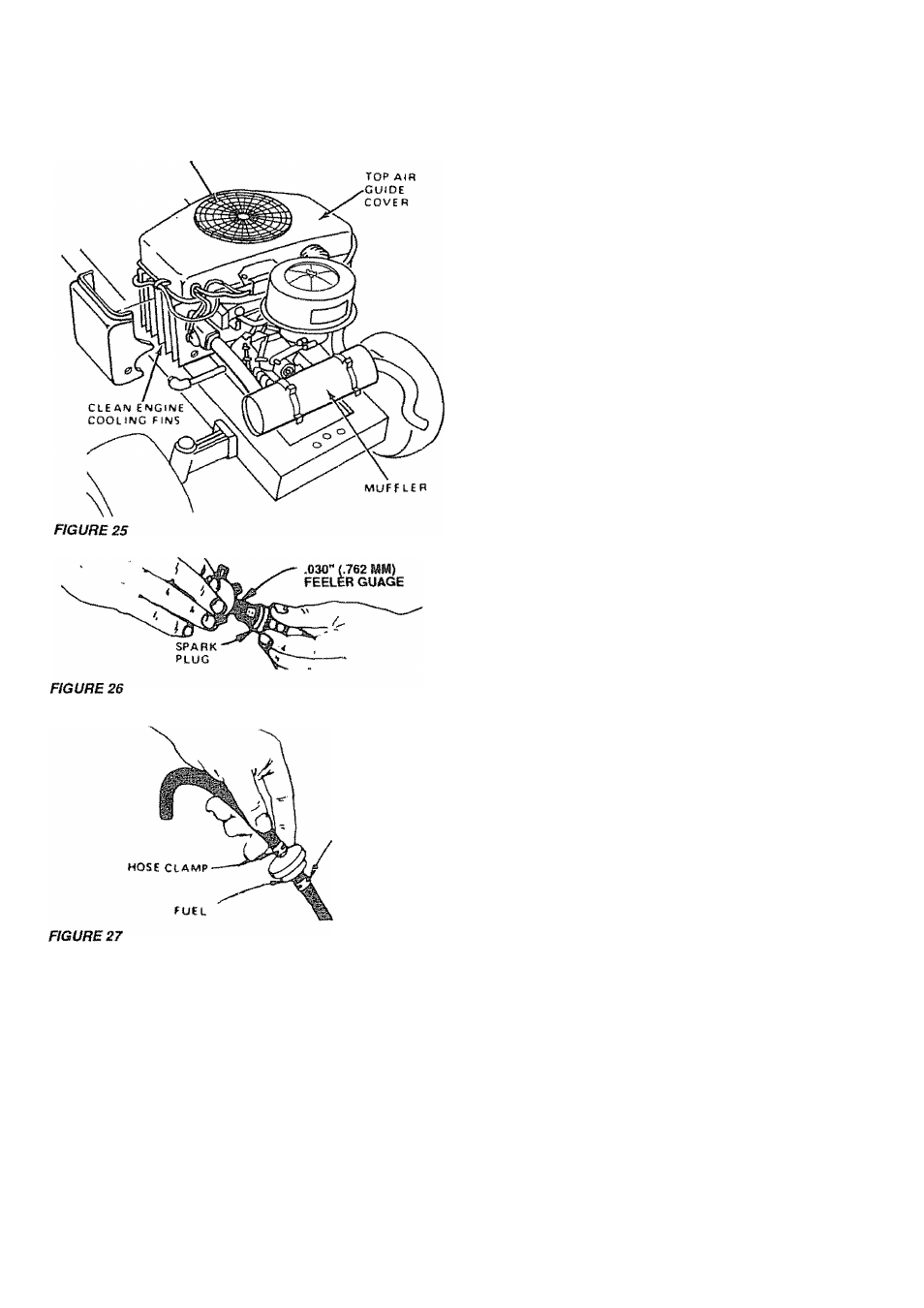

7. Clean Air Screen

Air screen (Fig. 25) must allow free-flow of air to prevent engihe

damage from overheating. Clean with

a

wire brush, compressed

ail orwater pressure to remove dirt, chaff, stubborn dried gum and

fibers.

ALWAYS WEAR SAFETY GLASSES WHEN

USING COMPRESSED AIR.

DO NOT TOUCH HOT MUFFLER, CYLIN

DER OR FINS AS CONTACT MAY CAUSE

BURNS.

8. Inspect Muffler

Inspect and replace corroded muffler as it could create a fire

hazard and/or damage (Fig 25).

9. Clean Engine Cooling Fins

Remove any dust, dirt or oil from engine cooling fins to prevent

engine damage from overheating. Air guide covers must be

removed (Fig. 25). Remove bolts to remove side and top covers.

See "HOOD REMOVAL,"page 21.

DO NOT TOUCH HOT MUFFLER, CYLINDER

OR FINS AS CONTACT MAY CAUSE BURNS,

Every WO Hours

DISCONNECT SPARK PLUG WIRES TO

PREVENT ACCIDENTAL STARTING BE

FORE MAKING ANY INSPECTION, ADJUST

MENT OR REPAIR (EXCEPT CARBURE

TOR). BE CAREFUL TO AVOID TOUCHING

HOT ENGINE OR MUFFLER COMPONENTS.

1.

Replace Spark Plugs

Replace spark plugs at the beginning of each mowing season or

every 100 hours, whichever comes first. Gap should be set at

0 030" (0.762 mm). (Fig 26),

2. Replace Air Cleaner Paper Cartridge

Refer to page 17.

3. Replace In-Line Fuel Filter

If fuel filter is clogged, obstructing fuel flow to carburetor, replace

ment is required

a. With engine cool, remove filter and plug fuel line sections

as removed from both ends of fuel fitter (Fig, 27).

b Place new fuel filter in position in fuel line. Be sure there

are no fuel line leaks and that fuel line is in proper

position in hose clamps.

BE SURE THERE ARE NO FUEL LINE LEAKS

AND THAT FUEL LINE IS IN PROPER POSI

TION IN HOSE CLAMPS.

4-

Change Engine Oil Filter

a. Drain crankcase of oil (refer to "CHANGE ENGINE OIL,"

page 15, through step d). Remove old filter (Fig. 19) by

turning counterclockwise.

b. Before installing new filter, apply a thin coating of oil on

surface of the rubber seal.

c Install new filter by turning clockwise until rubber seal

contacts the filter adapter, then tighten the filter an

additional 1/2 turn.

d. Refill crankcase with engine oil (see page 15 for oil

specifications). Add an additional 1/2 pint (.24 litres) oil

for the new filter capacity,

e. Start the engine. Check for and correct any oil leaks.

18