Electrical data and wiring, Rubber 0-ring and 2, Step 6 — connect refrigerant lines – Carrier 38CQ User Manual

Page 4: Table 4 — electrical data (60-hz)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

factory supplied with a No. 8 AccuRater piston for

installation in 28MQ048. For piston replacement

instructions, see AccuRater’’"''^ Servicing on page 15.

Step 6 — Connect Refrigerant Lines

to fittings on

unit suction and liquid service valves (Fig. 1).

Liquid service valve has flare fitting; suction service

valve has Compatible Fitting. Make suction line

connection first. Slide flare nut on liquid line, then

flare and connect liquid line. (Do not disassemble

AccuRater.) Unit Compatible Fitting permits

mechanical (quick-connect) or sweat connection as

described below. It is not necessary to flare system

liquid line if an accessory flare to Compatible

Fitting coupler is used for liquid line connection.

See Accessory Coupler (Fig. 5).

38CQ044,048 UNITS - When using 1-1/8 in.

field-supplied suction line, remove suction line

adapter taped to compressor suction line. Sweat

connect refrigerant suction line to 1-1/8 in. end of

adapter. Connect 3/4-in. end of adapter to unit

suction line Compatible Fitting.

When a 7/8-in. field-supplied suction line is

used on 38CQ039, a field-supplied 3/4-in. to

7/8-in. suction line adapter must be provided (not

required if 38CQ accessory tubing is used).

MECHANICAL CONNECTION TO COMPATIBLE

FITTING (Mate one set of connections at a time.)

1. Loosen nut on Compatible Fitting one turn. Do

not remove.

2. Remove plug and be sure 0-ring is in the groove

inside the Compatible Fitting.

3. Cut tubing to correct length.

4.

Insert tube into Compatible Fitting until it

bottoms.

5. Tighten nut until it bottoms on back coupler

flange. Keep tube bottomed in Compatible

Fitting while tightening nut.

SWEAT

CONNECTION

TO

FITTING (Use refrigerant tubing.)

COMPATIBLE

1

.

rubber 0-ring and

2

.

3.

4.

5.

Remove locking nut,

Schrader core from valve.

Cut tubing to correct length.

Insert tube in Compatible Fitting. Wrap top and

bottom of service valves in wet cloth to prevent

damage by heat. Solder with low temperature

(450 F) silver alloy solder.

Replace Schrader core.

Evacuate or purge system with field-supplied

refrigerant.

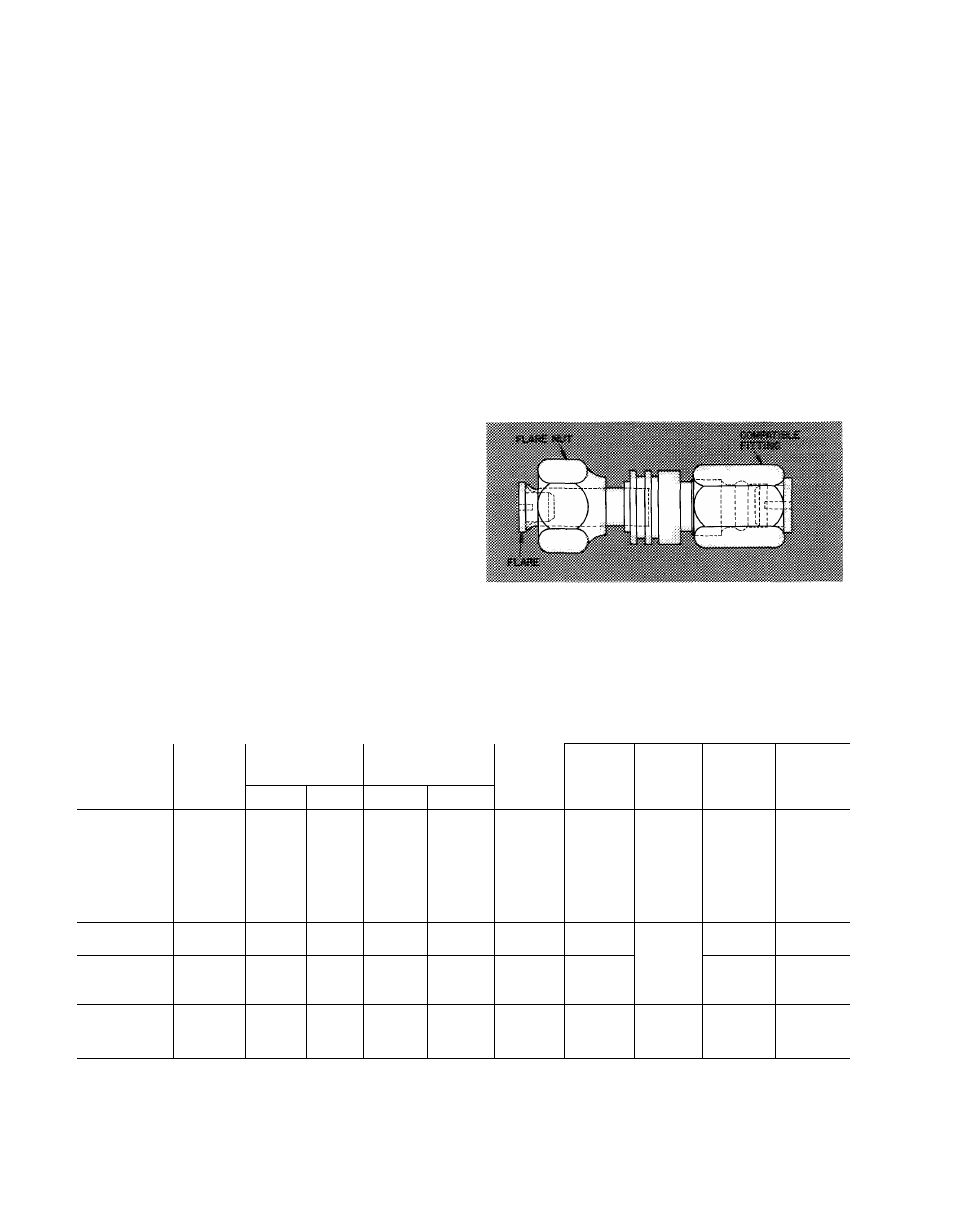

ACCESSORY FLARE TO COMPATIBLE COU

PLER is shown in Fig. 5. Attach flare nut on

coupler to flare fitting on unit liquid service valve.

Connect liquid line to Compatible Fitting using

mechanical or sweat connection. When mechanical

connection is made, use 2 wrenches when tighten

ing Compatible Fitting nut — one to hold coupler

and one to tighten nut. Liquid line must be flared

if coupler is not used.

Fig. 5 — Accessory Coupler

ELECTRICAL DATA AND WIRING

Field wiring must comply with local and

national fire, safety and electrical codes. Voltage to

unit must be within ± 10% of voltage indicated on

Table 4 — Electrical Data (60-Hz)

UNIT

V/PH

OPER

VOLTAGE*

COMPR

FAN

FLA

Power

Wire

Size

(AWG)

Max

Ft

Wire

Gnd

Wire

Sizef

(AWG)

Max

Fuse

Ampsi

Max

Min

LRA

RLA

38CQ015

41

9.0

.9

14

31

14

20

38CQ020

65

10.3

.9

12

40

12

20

38CQ027

82

17.7

2.4

10

42

10

40

38CQ033

230/1

254

207

88

19.8

2.4

10

36

10

45

38CQ039

94

22.2

2.4

10

33

10

50

38CQ044

106

25.0

2.4

8

46

8

50

38CQ048

106

25.0

3.0

8

46

8

50

200/

13.0/

2.0/

30/

38CQ033

230/3

254

180

87

11.5

2.0

12

40

12

25

38CQ039

79

17.4

2.4

12

31

12

40

38CQ044

200/3

229

180

87

18.6

2.4

10

35

10

40

38CQ048

87

18.6

3.0

10

35

10

40

38CQ039

67

15.0

2.4

12

41

12

35

38CQ044

230/3

254

207

70

16.7

2.4

12

36

12

35

38CQ048

70

16.7

3.0

12

36

12

35

BRANCH CIRCUIT

FLA

— Full Load Amps

LRA

— Locked Rotor Amps

RLA

— Rated Load Amps

*Permissible limits of the voltage range at which the units will

operate satisfactorily

fRequired when using nonmetallic conduit

^Maximum dual element fuse size

NOTES:

1

Fan motors are 200-v or 230-v, single phase

2

All units have 24-v control circuit which requires external

power source

3

Copper wire sizes based on 60 C Use copper or copper-clad

aluminum

wire

only

Use

latest

National

Electrical

Code

for

wire sizing

V