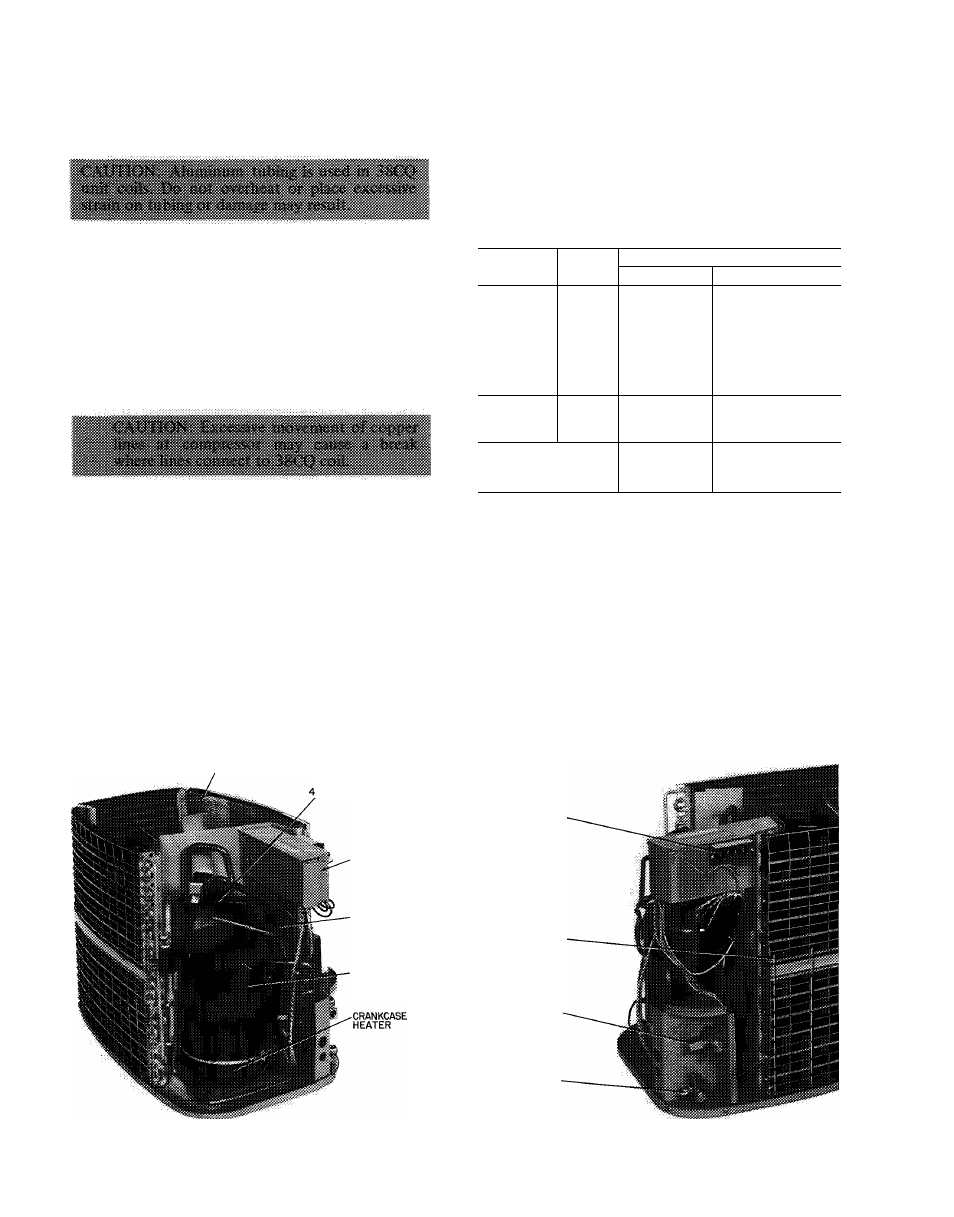

Fig. 31 — component location – Carrier 38CQ User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Compressor Removal

— See Table 7 for compressor

information and Fig. 31 for component location.

Follow safety codes, and wear safety glasses and

work gloves. Have quenching cloth available

(Step 7).

1. Shut off power to unit. Remove unit top

access cover and rear access wrapper.

2. Remove refrigerant from unit using refrigerant

removal methods described in Carrier Standard

Service Techniques Manual, Chapter 1.

3. Disconnect compressor wiring at compressor

terminal box.

4. Using a tubing cutter, cut suction and dis

charge lines at convenient place near com

pressor for easy reassembly to new compressor

with copper slip couplings.

5. Remove crankcase heater from compressor

base.

6. Remove compressor hold-down bolts and lift

compressor out.

7. Carefully unbraze suction and discharge line

piping stubs from compressor. If oil vapor in

piping stubs ignites, use quenching cloth.

8. Braze piping stubs (removed in step 7) on new

compressor.

9. Clean system. Add new liquid line heat pump

filter-drier as described below.

10.

Install new compressor in unit. Braze suction

and discharge lines to compressor piping stubs

(at points where cut, step 4) using field-

supplied copper couplings. Make sure com

pressor hold-down bolts are in place. Connect

wiring.

11. Evacuate and recharge unit.

FILTER-DRIER — Install accessory heat pump

filter-drier (Table 3) in system liquid line when

refrigerant system is opened for service as de

scribed under Compressor Removal. Position drier

in liquid line at convenient location. Do not use a

standard single-pass filter-drier.

Table 7 — Compressor Data

UNIT

V/PH

PRODUCTION —

Model*

Oil Recharge (oz)

38CQ015

38CQ400994

20

38CQ020

MD2023HB

44

38CQ027

MD3023HB

44

38CQ033

230/1

MC3423HB

44

38CQ039

PC4Ó16HD

64

38CQ044

PC5316HD

64

38CQ048

PC5316HD

64

38CQ039

PF4616HD

64

38CQ044

200/3

PF5316HD

64

38CQ048

.

PF5316HD

64

38CQ039

PG4616HD

64

38CQ044

230/3

PG5316HD

64

38CQ048

PG5316HD

64

‘Refer to Service Parts catalog for replacement compressor

model numbers

Pumpdown Procedure (Cooling Cycle)

— The

38CQ units may be pumped down in order to

make repairs on low side of system without losing

complete refrigerant charge. Ensure unit is in

cooling mode.

1. Attach pressure gage to suction service valve

service port.

2. Frontseat the liquid line valve.

3. Start unit and run until suction pressure reaches

5 psig (see Caution).

4. Shut unit off and frontseat suction valve.

5. Vent remaining pressure to atmosphere.

FAN COMPARTMENT

-WAY VALVE

CONTROL BOX

DISCHARGE LINE

MUFFLER

(039,044,048)

COMPRESSOR

CONTROL WIRING

TERMINAL BOARD

ACCUMULATOR'

SUCTION

LINE

SERVICE VALVE-

LIQUID LINE

SERVICE VALVE

Fig. 31 — Component Location

14