Table 3 — accessories, Piping connections, Before connecting refrigerant lines – Carrier 38CQ User Manual

Page 3

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Table 3 — Accessories

PART NO.

DESCRIPTION

38CQ900081

38C 0900111

Low-Voltage Control — Honeywell Thermostat HH07AT071 and

Thermostat Subbase HH93AZ073 — (Automatic Changeover)

38CQ900182

38GS900381

Low-Voltage Control — Honeywell Thermostat HH07AT071 and

Thermostat Subbase HH93AZ075 — (Manual Changeover)

Service Sentry (Six HN65CT002)

____

38CQ900061

38CQ900091

Start Capacitor and Relay Package

Flare

(3/8-in.)

to

Compatible

(3/8-in.)

Couplings

(Two-Pack)

Liquid Line Filter-Drier

38RQ900001

Emergency Heat Relay (Required with 2 outdoor thermostats.)

(Service Parts)

38RQ900021

1

h

H22AG110

Outdoor

Thermostat

(Six

38RQ900032)

Optimizer Control

38CQ900141

Solid State Time Guard (24 volt)

TUBING

Length

Liquid

Suction*

TUBING

UNIT

1 ube bnd

PACKAGE

(ft)

OD

1 ube End

OD

OD (in.)

(in.)

OD (in.)

(in.)

Evap

Cond

38GC900031

10

%

%

Va

V4t

Va

38GC900041

18

%

Va

Va

V4t

Va

38GS900221

25

%

Va

Va

V4t

Va

38CQ015,020

38GC900061

35

Ha

Va

Va

V4Î

Va

38GC900191

50

V

4

___

Va

Va

V4t

V4

38GC900071

10

V

Va

4

V

4

y

4

38GC900081

18

V

4

V

4

V

4

y

4

38GC900091

25

4

V

4

V

4

V

4

y

4

38CQ027,033

38GC900101

35

V4

Va

V4

V

4

y

4

38GC900m

50

V

4

Va

V

4

V

4

y

4

38CQ900001

18

V

4

V

4

Vat

V

4

y

4

38CQ9000n

25

4

Va

Vai

4

4

38CQ039,044,048

38CQ900021

35

V

4

Va

V

4

V

4

V

4

38CQ900031

50

V4

Va

Vai

4

*Suction line is insulated and has a 90 bend at one end

fFor 5/8-in evaporator connection, cut off 3/4-in end

ICapacity reduction may occur when 7/8-in accessory tubing is used

on 38CQ044.048

PIPING CONNECTIONS

The 38CQ units can be connected to indoor

units using Carrier accessory tubing package or

field-supplied tubing of refrigerant grade. See

Table 1 (with notes) for unit piping connection

type, size and line size recommendations and

Table 3 for accessory tubing sizes. Maximum

length of refrigerant piping allowed is 50 feet

A capacity reduction will result if accessory

tubing is used in 38CQ044,048 systems. For

example, when a 25-ft, 7/8-in. accessory tubing

package is used, there will be a capacity reduction

of 1-1/2%. For maximum capacity, use 1-1/8 in.

suction line as recommended in Table 1.

When other than 25 ft of interconnecting

piping is used, follow special requirements de

scribed in Refrigerant Charging. Do not use less

than 10 ft of accessory liquid line. Do not cut

5/16-in. or 1/4-in. liquid line. Do not cut 7/8-in.

suction line. Bend or coil to fit.

Do not use damaged or contaminated tubing.

Always evacuate or purge evaporator coil and

tubing system (use field-supplied refrigerant, not

unit refrigerant).

When making tubing connections, be sure to

provide clearance at unit for electrical connections.

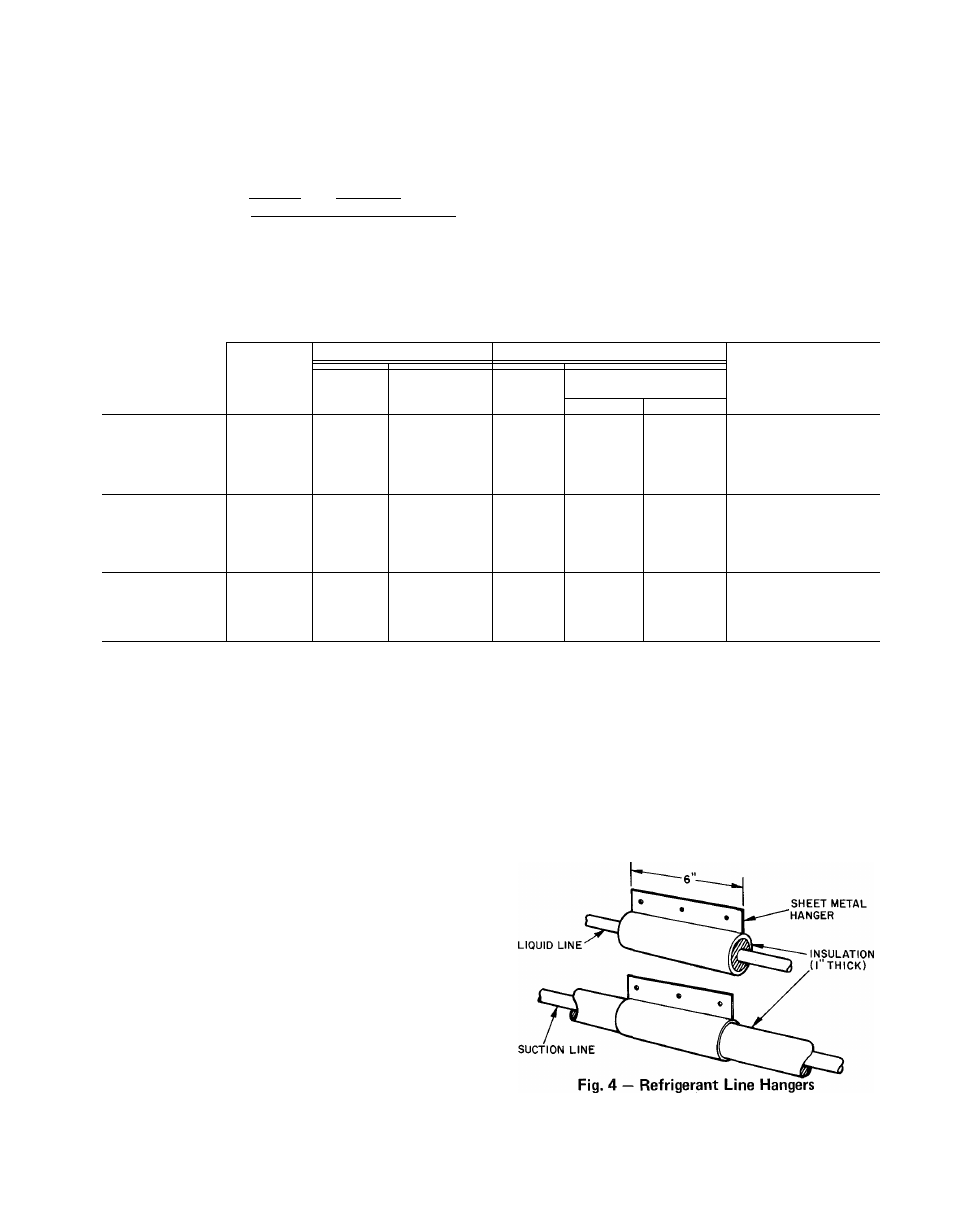

To assure noise-free installation, isolate refrig

erant lines from ductwork and framing or where

they run thru stud spaces, enclosed ceilings or pipe

chases. Use isolation hangers (Fig. 4), as rigid

fastening may transmit pulsations to structure,

creating an objectionable rumble. Do not attach

liquid line to uninsulated suction line. When

running thru structure, surround all lines with 1-in.

insulation to prevent transmission of vibration.

Before Connecting Refrigerant Lines,

replace the

AccuRater'^'''^ refrigerant control piston in the

indoor coil as required. See Table 2. The 38CQ048 is