Unit single-phase compressors – Carrier 38CQ User Manual

Page 13

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Fig. 29 - 38CQ048 with 40FS200/28MQ048

Cooling Cycle Charging Chart (R-22)

300

280

260

>240

fE 220

£ 180

140

120

WET-BULB TEMP

AIR ENT

OUTDOOR UNIT{F)

9F

-I0.5F

M

15 F

23.5F

33F

43F

I

DRY-BULB TEMP

AIR ENT

INDOOR UNIT (F)

20

30

40

50

60

SUCTION PRESSURE AT SUCTION SERVICE PORT

70

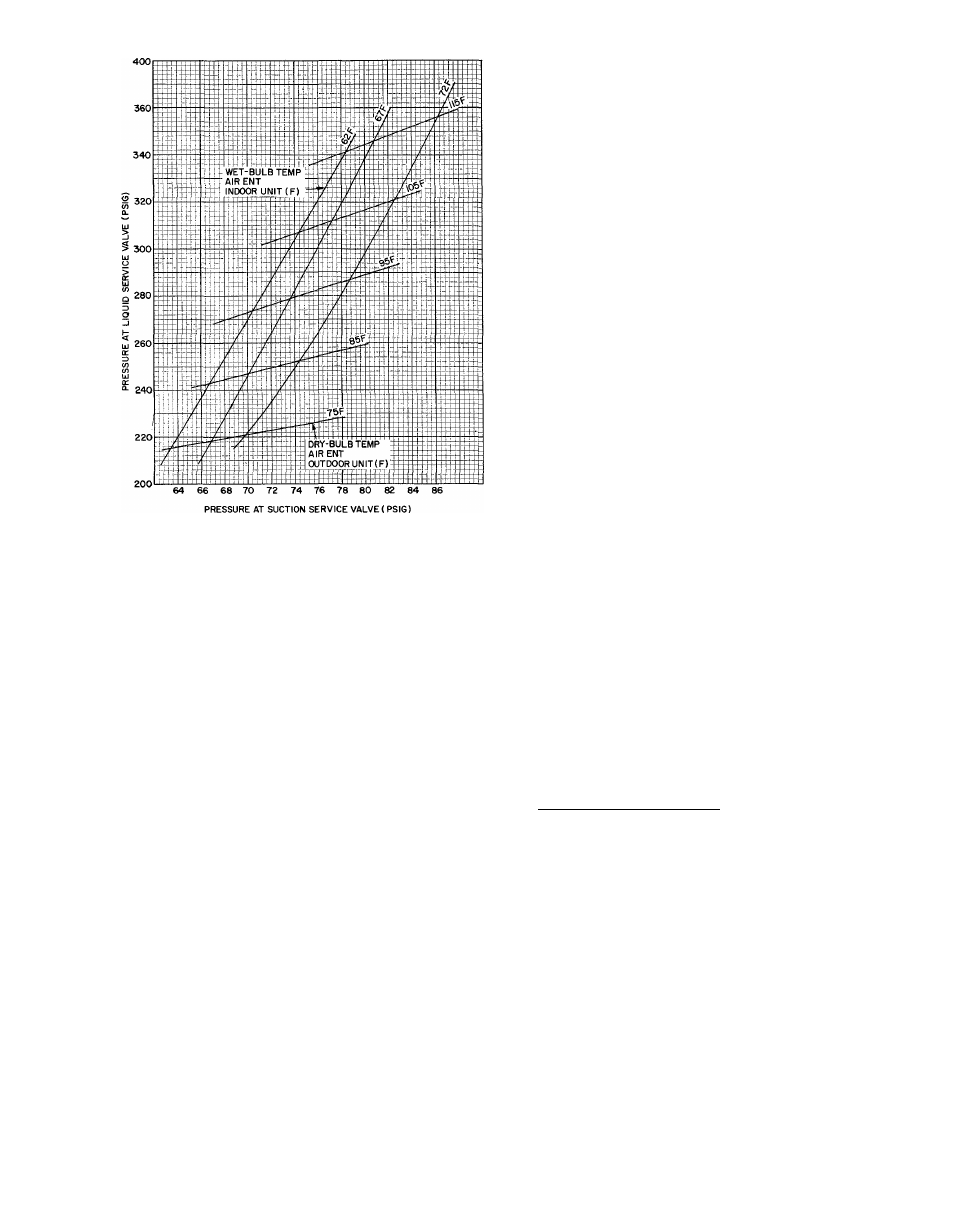

Fig. 30 - 38CQ048 with 40FS200/28MQ048

Heating Cycle Operation Check Chart (R-22)

Unit Single-Phase Compressors

COMPRESSORS OF THE SPLIT CAPACITOR

(PSC) TYPE require an equalized system pressure

to start. When supply voltage is within 10% limit

and compressor does not start, give compressor a

temporary capacitance boost. See Carrier Standard

Service Techniques Manual, Chapter 2, for details.

Use a 130-mfd start capacitor. Connect wires with

insulated probes to each capacitor terminal. Touch

probes to each side of run capacitor or to

compressor motor terminals R and S. Start com

pressor; pull probes away after 3 seconds Dis

charge start capacitor. Run compressor for 10

minutes, then shut off and allow system pressure

to equalize. Try restarting without boost capacitor.

If after 2 attempts (without boost capacitor) the

compressor does not start, add an accessory start

thermistor (PTC device). If after 2 more attempts

the compressor does not start, remove thermistor

and add an accessory start capacitor relay package.

COMPRESSORS THAT ARE EQUIPPED WITH A

COMPRESSOR START THERMISTOR (PTC

device): if compressor does not start, check the

thermistor with an ohmmeter as described below.

Earlier unit models have a 50-ohm thermistor (with

2-prong connections), later models have a 25-ohm

thermistor (with 3-prong connections). If indoor

coil does not have a bleed-type expansion device, it

may be necessary to remove start thermistor and

replace with accessory start capacitor and relay.

Checking Start Thermistor

1. Shut off all power to unit and wait 5 minutes

for thermistor to cool to outdoor temperature.

2.

Measure resistance of thermistor with ohm-

meter. Normal resistance readings at 75 F out

door temperature are: 50 to 90 ohms for

50 ohm thermistor; 25 to 50 ohms for 25 ohm

thermistor.

3. If ohmmeter resistance reading is 0 or much

higher than 50 or 90 ohms, the thermistor is

defective and must be replaced.

If start thermistor is good and compressor does

not start, disconnect the thermistor from starting

circuit and give compressor a temporary capaci

tance boost as described above. Run compressor

for 10 minutes, then shut off and allow system

pressure to equalize. Reconnect start thermistor

and try restarting compressor without boost capa

citor. If aher 2 attempts the compressor does not

start, remove thermistor and add an accessory start

capacitor relay package.

13