Chapter 7. diagnostics & troubleshooting, Led indications, Troubleshooting table – Winco DPG-2145-001 User Manual

Page 46

Manual 36526F

DPG-21XX-00X Digital Controllers

Woodward

38

Chapter 7.

Diagnostics & Troubleshooting

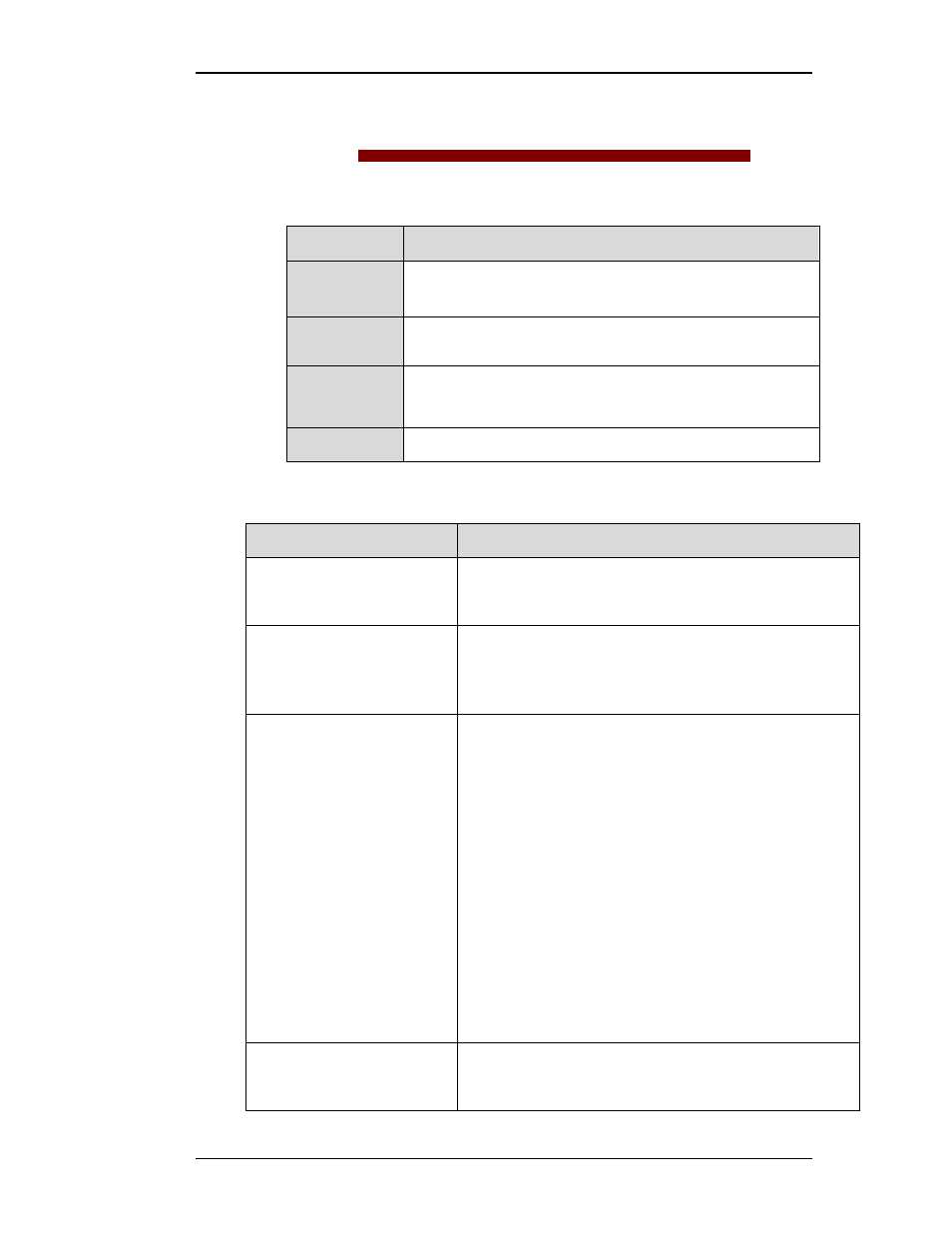

LED Indications

LED

STATE

MEANING

Off

Controller is either not currently powered, or is being reverse

powered. (Check polarity of supplied power.) If correctly

powered, then controller is malfunctioning.

Blinking Slow

(1/2 Hz)

Controller is powered, but not sensing a speed signal. OK if

engine is not running. If the engine is running, then this

indicates a fault with the speed signal.

Blinking Fast

(1

½

Hz)

Controller is powered and an engine speed signal is being

detected. If the engine is not running, then this indicates

electrical noise on the speed signal wires.

ON

and Not

Blinking

Controller is powered and is malfunctioning. Replace controller.

Troubleshooting Table

SYMPTOM

REMEDY

LED Display Does Not Light

Up When Controller Is

Powered

BAT + and BAT

– leads are reversed. Check wiring.

Battery voltage too low. Should measure between 9

–30 Vdc.

Controller is defective. Replace it.

Unable to Modify Parameters

The parameter’s value is the maximum value allowed.

The parameter’s value is the minimum value allowed.

Universal PST not communicating with the controller.

Keypad failure, replace unit.

Engine Does Not Start

Actuator leads not connected or shorted.

No fuel source. Turn on fuel source.

Battery voltage is low. Charge or replace the battery.

Set speed is lower than crank speed. Increase the set speed.

Startup Rate setting is too low. The target speed ramps up

too slow.

Startup Limit is too low, limiting the actuator drive signal too

much.

Is the MPU speed signal present? It should read 2.0 VRMS

minimum. Adjust magnetic pickup (MPU) gap. Try reversing

the MPU leads.

If a speed signal is present, measure actuator output duty

cycle. If not greater than 5%, then restore all parameter

values to factory default settings and crank the engine again.

Final target speed must be greater than crank speed before

the controller will attempt to drive the actuator open.

Engine Overspeeds at Startup

Increase the Proportional value.

Increase the appropriate Gain value.

Decrease the Startup Ramp Rate.