Figure 1, Attention – Tuffy Security 149 User Manual

Page 2

Page 2 of 2 – 12/20/06 – Rev10/12/2012

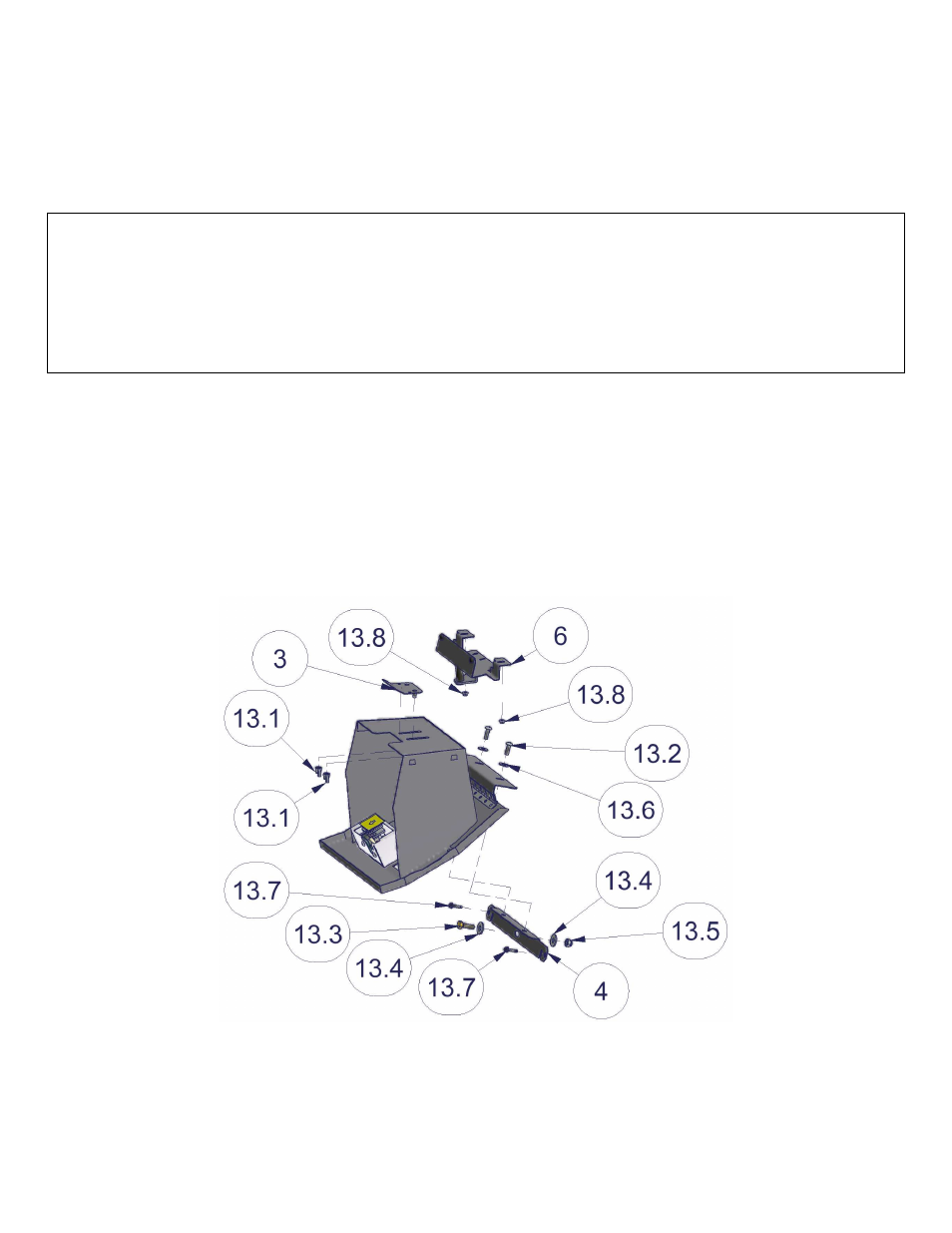

4. Remove the original two nuts #13.8 at the top inside the glove box opening by where the lock catch was removed.

Save these you will reuse them. (See Figure 1)

5. Maneuver #4 Mounting bracket between the plastic dash panel and the frame at the bottom of the glove box opening

then re-fasten the (2) original screws #13.7. (See Figure 1) If the other original dash screws were removed they can

be re-fastened and the plastic panel can be popped back in.

6. Mount the #6 Latch Bracket to the inside top of the dash opening by re-fastening the original nuts #13.8. (See Figure

1)

OPTIONAL SECURITY STEP

WARNING! - Make sure that there is nothing behind the dash that will be damaged by the drill bit when drilling.

(2007-2010 JK) Drill a 3/8” hole in the dash frame corresponding with the center hole in Mounting Bracket #4. Fasten

using 5/16 x 1” bolt #13.3, 5/16 Nut #13.5, and 5/16” Washers #13.4. (See Figure 1)

(2011-up JK) Drill a 5/8” hole in the plastic dash panel and subsequently drill a 3/8” hole in the dash frame corresponding

with the center hole in Mounting Bracket #4. Fasten using 5/16 x 1” bolt #13.3, 5/16 Nut #13.5, and 5/16” Washers #13.4.

(See Figure 1)

7. Position the Glove box in the dash so the mounting holes by the hinge line up with the holes in the #4 Mounting

Bracket and fasten them together using (2) ¼-20 x ¾ screws #13.2 and (2) ¼ Washers #13.6. (See Figure 1)

8. Check the lock operation and fit clearances. All the mounting holes are obrounded so the fit can be adjusted by

loosening the fasteners and maneuvering the box as required.

9. Fasten the #3 Door stop to the back of the Glove box using (2) ¼-20 Wingnuts #13.1. Enable it by partially shutting

the Glove box past the #6 Latch bracket, slide the #3 Door stop up and tightening the Wingnuts. When the door is

opened the #3 Door stop will hit the #6 Latch bracket preventing the door from opening further. (See Figure 1)

FIGURE 1

ATTENTION:

FREQUENT LUBRICATION IS NECESSARY ON THE LOCKING SYSTEM

The pushbutton lock contains an “O” ring seal to protect the interior from dust and water. If this mechanism is not lubricated regularly it will become

difficult to operate and it may not return to its home position preventing the key from operating the lock. If this happens simply pull up on the pushbutton

to manually bring it back to its home position. Lubricate the pushbutton with a light lubricant such as silicone spray. The pushbutton may have to be

periodically disassembled and cleaned.

Call (970) 564-1762 for Technical Support