Flow meter, Boom control valves, Pressure transducer – TeeJet 844-E Sprayer Control User Manual

Page 8: Flow meter boom control valves pressure transducer, E sprayer control

4

www.teejet.com

844-E Sprayer Control

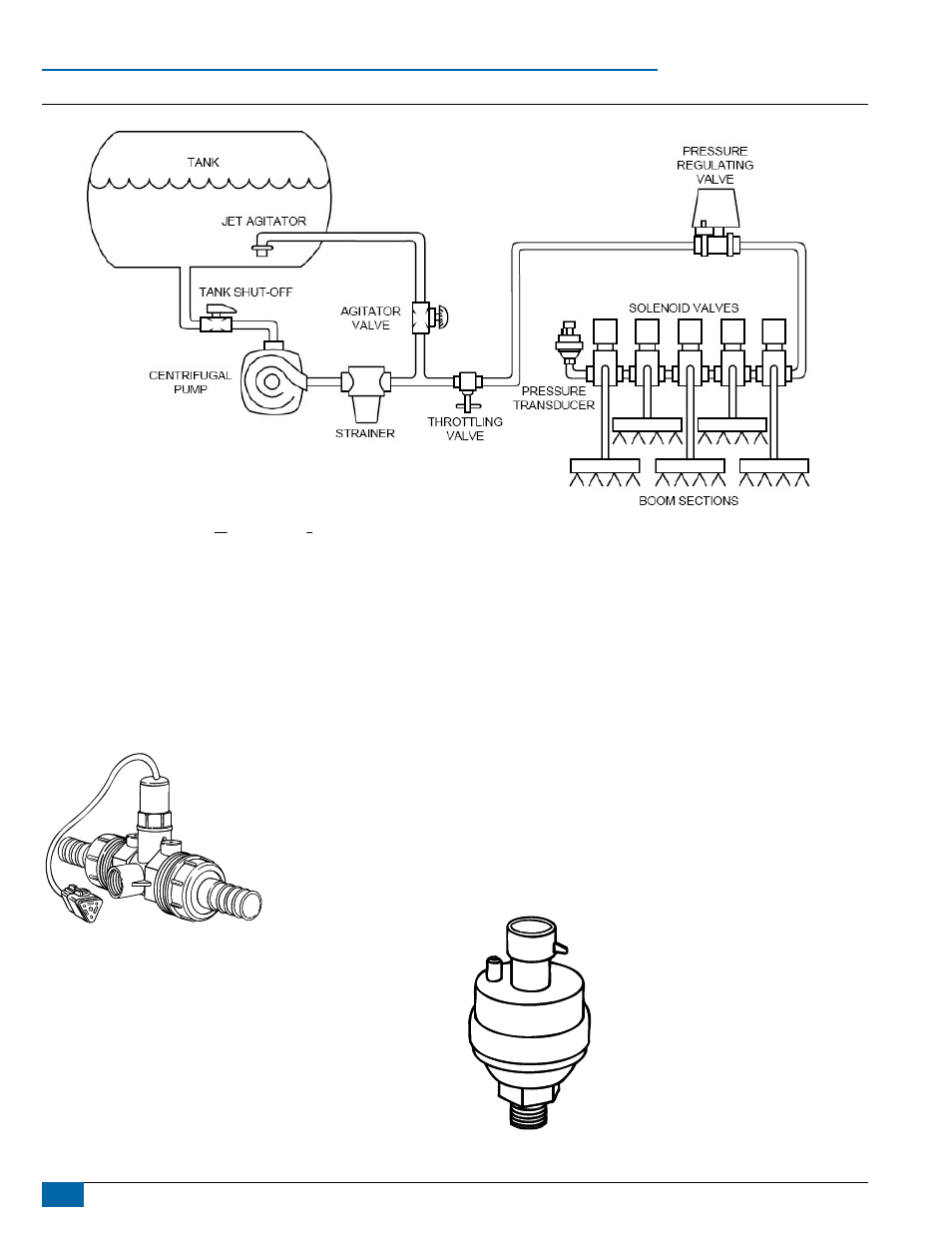

Figure 4: Throttling Plumbing Diagram - Pressure Based System

Flow Meter

To ensure accurate readings, the flow meter (if used) must be mounted

10″ to 12″ (25-35 cm) from other pipe fittings, preferably in a vertical

position with the flow going up. It should also be mounted with the

direction of flow arrow pointing toward the boom control valves. Refer to

Figures 2 and 3.

Be sure the flow meter is plumbed so that all liquid passing through it

is routed to the booms and not back to the tank. When using three-way

boom control valves, refer to page 13 of this manual for programming

guidelines.

boom Control Valves

The Boom Control Valves are connected in tandem and centered in

front of the boom sections. See the Control Valve Instruction Manual for

mounting instructions. If using three-way valves, refer to the instruction

manual of the valves you are using for valve calibration instructions.

pressure transducer

The pressure transducer (if used) should be installed as close to

the spray tips as possible. Normally this is at the boom control valve

assembly. Refer to Figures 1 through 3. Mount the unit vertically on a

short stand pipe to help protect the sensor.

NOTE: Pressure drop, to some degree, is found in most plumbing

systems. Pressure drop is created when there is any kind of

restriction in the spray line that reduces flow rate and is quite

often produced between the boom control valve assembly and

the spray tips. If one of the boom sections on the sprayer is

always used, the pressure transducer can be installed on that

particular boom section, minimizing any potential pressure drops

between the sensor and spray tips. If the pressure drop in your

system is greater than 5 psi (0.3 bar), you should consider this

as an alternative location for the pressure transducer.

Check all components to make sure they are mounted securely to avoid

excessive vibration.