Speed step 2 - installing the wheel magnets, Speed step 3 - installing the magnetic sensor, E sprayer control – TeeJet 844-E Sprayer Control User Manual

Page 10

6

www.teejet.com

844-E Sprayer Control

Speed Step 2 - installing the wheel Magnets

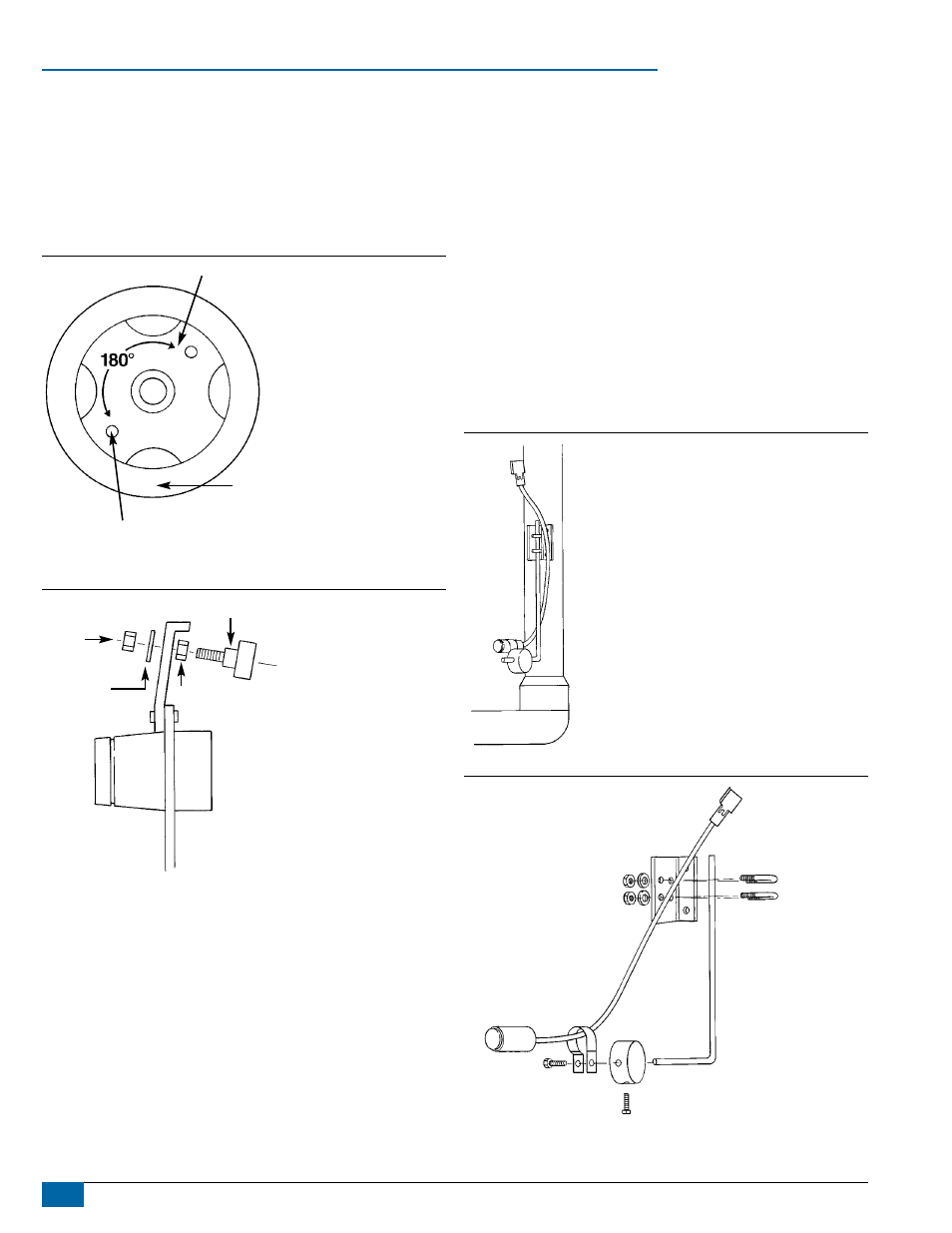

Check for pre-drilled holes in the wheel rim. If pre-drilled holes are not

available, layout a pattern as shown in Figure 7 and drill two 3/8″ (10

mm) holes near the outer edge of the rim if possible, and 180° from

each other.

Place the magnets into each of the two holes on the inside rim and

securely fasten them using the nuts and washers provided.

Figure 7: Magnet Locations

TIRE

WHEEL

3/8˝ (10 mm)

HOLE FOR

MAGNET

Figure 8: Magnet Assembly

NUT

NUT

MAGNET

WASHER

Speed Step 3 - installing the Magnetic

Sensor

The flat, pressed L bracket of the wheel speed sensor kit should be

secured to a vertical member near the non-driven wheel. The round,

right angle steel bracket is then secured to the flat bracket with the

two U-bolts and necessary hardware provided. The round, right angle

bracket is then used to secure the magnetic sensor mounting clamp.

The magnetic sensor should be inserted into the mounting clamp and

positioned within 1/8″ to 3/8″ (3-10 mm) of the wheel magnet. Tighten

the sensor clamp using the clamp screw per Figure 10.

Your installation will likely vary from the example. It may be necessary

to customize the installation to accommodate your specific machine.

Keep in mind that the two magnets must be spaced an equal distance

around the wheel. The magnetic sensor must be mounted in-line with

the magnets and positioned within 1/8″ to 3/8″ (3-10 mm) from each

magnet as they pass the Sensor assembly.

Figure 9: Sensor Mounting

Figure 10: Sensor Assembly

CLAMP

SCREW

SENSOR

BRACKET

FLAT

L BRACKET