Wiring dia gram, Electrical information, Cc 1 – Reznor R6GN Unit Installation Manual User Manual

Page 30: Ibc ofc, Cc 2

30

ElEctRIcal INFoRMatIoN

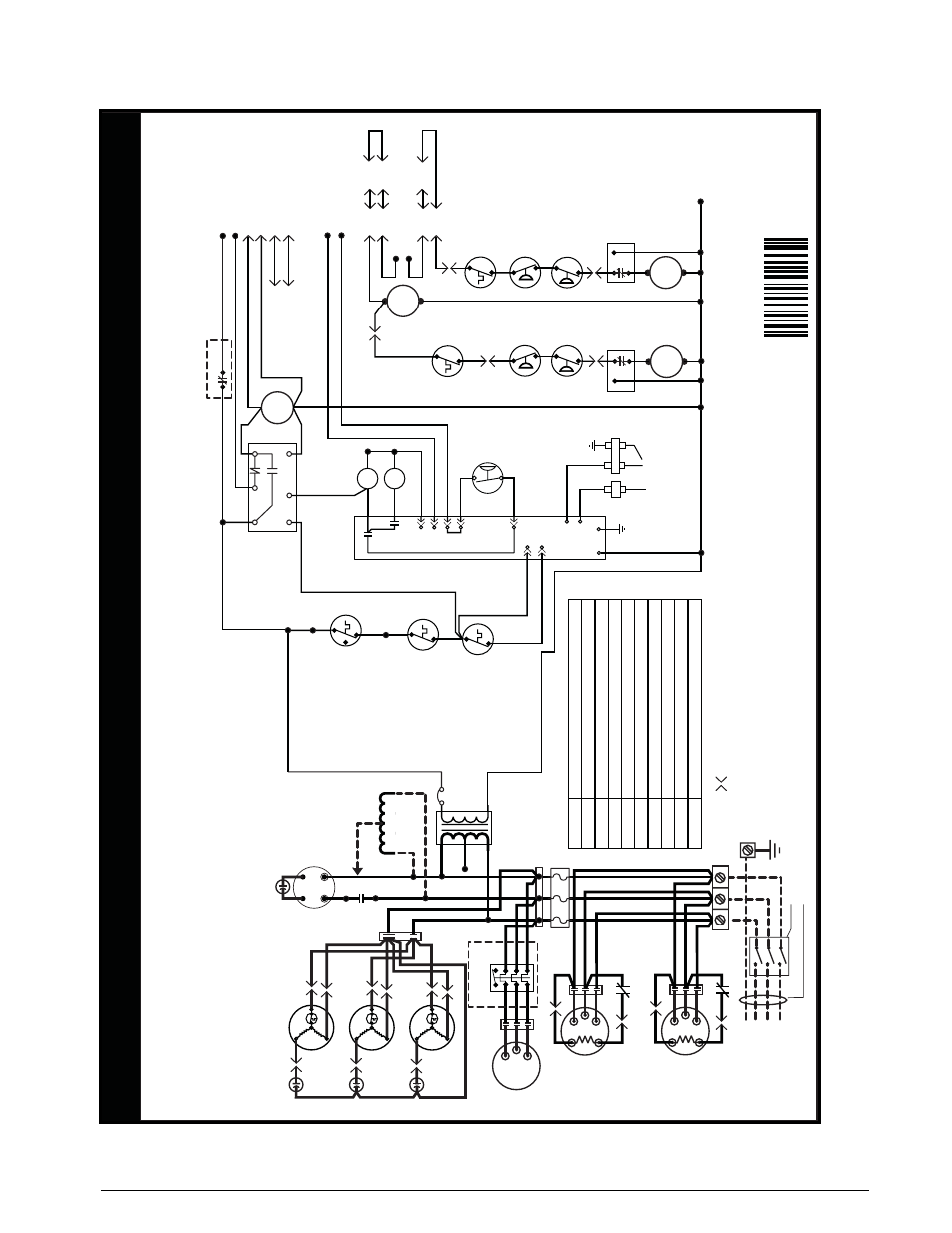

Figure 15. Ladder Diagram - 150/180 Series

WIRING DIA

GRAM

NO

TES:

1.

Couper le courant

av

ant de faire letretien.

2.

Empl

oy

ez uniquement des conducteur

s en cuivr

e.

R6GN-150*/180* Series Co

nv

er

tible

Pa

ck

ag

e Gas Heat/Electric Air Conditioner

1.

Disconnect all po

wer bef

ore servicing.

2.

For suppl

y connections use copper conductor

s onl

y.

3.

If an

y of the original wire as supplied with the furnace

mu

st be replaced

, it m

ust

be replaced with wiring material ha

ving a temperature rating of at least 105C.

4.

For supp

ly

wire ampacities and

ov

er

current pr

otection

, see unit rating label

.

5.

Remo

ve white wire fr

om PO

WER BLOCK- L3 and connect to autotransf

ormer red wire

.

6.

For 120C Models on

ly

. For 208V operation remo

ve wire fr

om 230V tap an

d

place on 208V tap.

Three Phase 60 Hz.

208-230/460

Volt

710849A

01/11

(Replaces 7108490)

Field Supplied Disconnect (3Phase

Po

wer Only

)

Fo

r supply connections use copper conductors onl

y.

Unit

Te

rm

inal

Bloc

k

T2

T3

T1

IB

C

Indoor Bl

ow

er Motor

L1

L2

L3

GN

D

FUSE

BLOCK

1

2

3

BK

WH

INDUCE

R

MO

TO

R

BO

R

Tr

ansf

or

mer

See Note

6

Au

totransf

or

mer

460V

Units Only

RE

D

See Note

5

L3

L2

RD/WH BK

LV

T-C (24V COM.)

CC

1

24V Ho

t

Max

Temp

.

Limi

t

24V Common

Flame

Rollout

Switch

Upper

Seconda

ry

Limi

t

IBC

OFC

2

3

1

2

3

1

CC

2

CLOR1

(Field

Installed

Option

)

Stage

1

Ev

ap

.

Freez

esta

t

Lo

w

Pressure

Switc

h

High

Pressure

Switc

h

CLOR2

(Field

Installed

Option

)

E-5

E-4

LV

T-Y1 (Stage 1 Cool)

LV

T-Y2 (Stage 2 Cool)

E-2

E-1

LV

T-W1 (Stage 1 Heat)

LV

T-W2 (Stage 2 Heat)

E-8

E-15

E-14

BOR

95

96

LV

T-

G

LV

T-

R

E-9

To

Mix

ed Air Sensor

(When Econ Used)

TDR -

Time Dela

y Rel

ay

IBC - Contactor

, Indoor Blo

wer Motor

CC1&2 - Contactor

, Stage 1&2 Compressor

OFC - Contactor

, Outdoor

Fa

n

CCH - Crankcase Heaters

, Stage 1&2 Compressor

LV

T - Lo

w

Vo

ltage

Te

rm

inal

BR - Blo

wer Rela

y

CLOR1 & 2 - Compressor Lo

ck

out Rela

y

BOR - Bl

ow

er Ov

er

load Rela

y

TB -

Te

rm

inal Board - HX

S

S

S

C

C

C

R

R

R

Compressor 2

T2

T1

T3

CC

2

CC

2

SC-4

SC-5

Compressor 1

T2

T1

T3

CC

1

CC

1

SC-4

SC-5

Outdoor

Fan Moto

r

Outdoor

Fan Moto

r

Outdoor

Fan Moto

r

BK

WH

C1-3

C1-1

C1-2

C2-3

C2-1

C2-2

C1-3

C1-1

C1-2

E-4

E-2

E-1

Stage

2

Ev

ap

.

Freez

esta

t

Lo

w

Pressure

Switc

h

High

Pressure

Switc

h

SC-1

SC-1

SC-2

SC-2

E-3

PO

WER BLOCK

P1-2

P1-8

P1-3

P2-3

K2

S1

S2

IGNITION

CONTR

OL

G

C

R

L

COM

NC

NO

BLO

WE

R

TIM

E

DEL

AY

K1

P2-4

W1

W2

HV

TRANSFORMER

FS

P2-1

COM

P1-9

P1-6

TB-3

TB-2

GAS

VA

LV

E

PRESSURE

SWITCH

SP

ARK

IGNI

TO

R

FLAME

SENSOR

IC-L1

IC-IND

IC-K

4

GND

High Limit Input

Rollout Switch Input

C

230V

208V

95

96

- Indicates plug connection.

Letter Indicates which plug.

Number indicates pin location.

E - Economi

ze

r

SC - Saf

ety Circui

t

IC - Ignititon Control

Status Light

(Red)

Ignition Control

Fa

ilure Code

Steady On

2 flashes

Operation Nor

mal

3 flashes

4 flashes

5 flashes

6 flashes

7 flashes

8 flashes

9 flashes

10 flashes

Pressure/cent

rifugal

sw

itch open with inducer on

Loc

kout from too man

y

fa

iled ignition tr

ie

s

Loc

kout from too man

y flame losses

High temperature

sw

itch open

Rollout

sw

itch open

Flame present with gas off`

Exceeded max limit tr

ips in one call

fo

r heat (5)

Gas

Va

lv

e

Fa

ul

t

Pressure/cent

rifugal

sw

itch closed with inducer of

f

4A

OPTIONAL

OPTIONA

L