Warning – Reznor R6GN Unit Installation Manual User Manual

Page 13

13

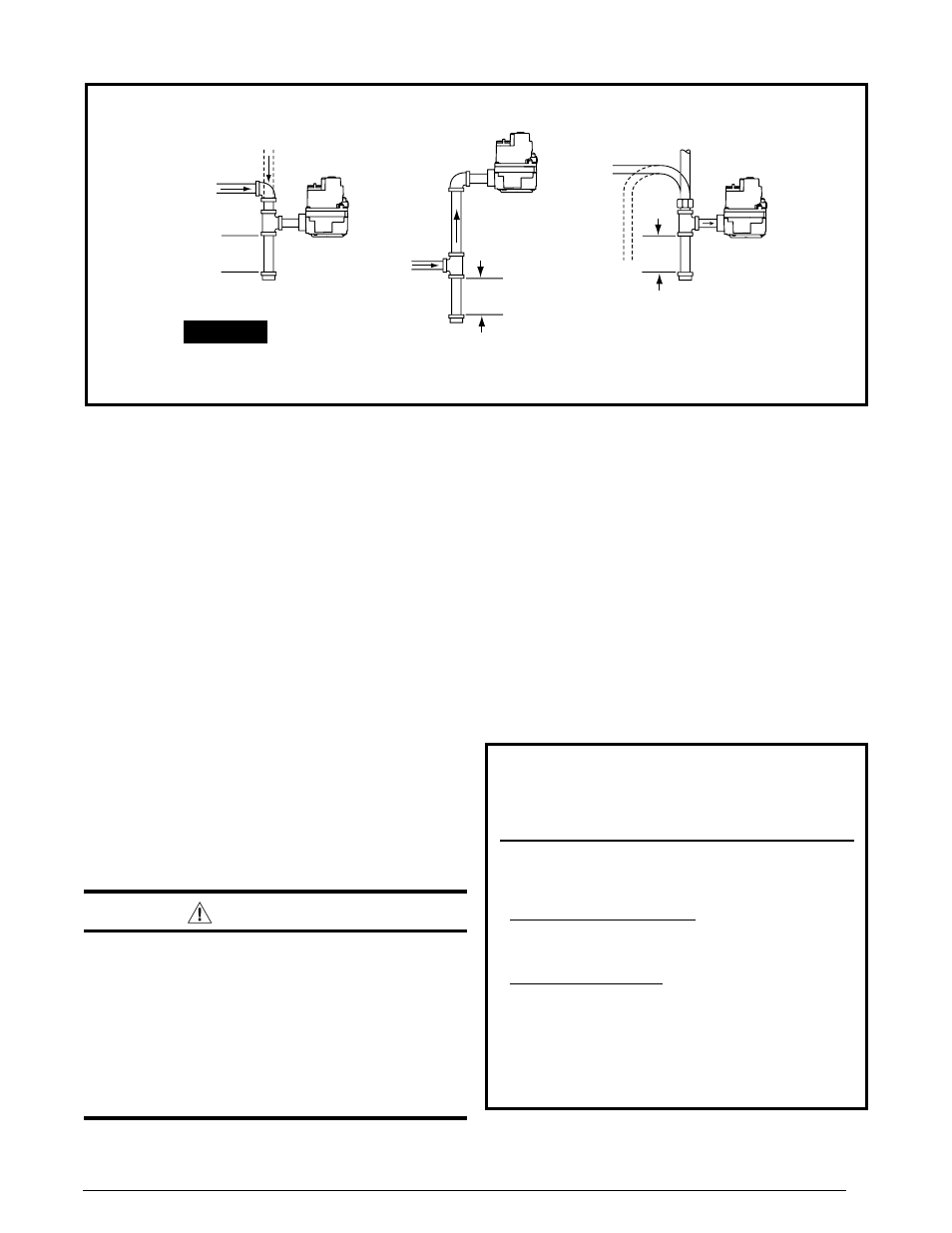

Figure 9. Typical Gas Service Connection

1. All piping must comply with local codes, ordinances, and/or National Fuel Gas Codes.

2. A manual shutoff valve must be installed within 6 feet of this equipment.

3. Always include a drip leg in piping.

NOTES:

Gas Valve

Gas Valve

Riser

3 in.

Minimum

Horizontal

Drop

Piped Gas Supply

Tubing Gas Supply

3 in.

Minimum

Horizontal

Drop

Gas Valve

3 in.

Min.

Riser

Piped Gas Supply

• If installing this unit above 2,000 feet, the input rate must

be reduced 4% per 1,000 feet of altitude (Example: 12%

at 3,000 feet, 16% at 4,000 feet, etc). Always round up

to the next highest value of 1,000. So an installation

at 3,120 feet is derated by 16% due to rounding up to

4,000. NOTE: This deration is necessary to compensate

for low atmospheric pressure at high altitudes. Generally

this will require obtaining the gas heating value from

the local gas utility and replacing the burner orifices.

• Tables 9 & 10 (page 34) list the correct orifice size and

high elevation conversion kit approved for this unit at

various altitudes. Use the Installation Example below

to determine the unit rating and orifice size.

• After changing the orifices, it is required that you measure

the gas input rate by clocking the gas meter and using

the local gas heating value. See Verifying & Adjusting

the Firing Rate (page 16).

IMPoRtaNt NotE! Observe the action of the burners

to make sure there is no yellowing, lifting or flashback of

the flame.

Conversion to LP/Propane

WaRNING:

The furnace was shipped from the factory

equipped to operate on natural gas. Conversion

to LP/propane gas must be performed by

qualified service personnel using a factory

supplied conversion kit. Failure to use the

proper conversion kit can cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

INStallatIoN EXaMPlE:

Elevation: ..................................................3,890 feet

type of Gas: ..................................................Natural

Unit Model: ...................................R6GN-150C270C

At 4,000 feet, the unit needs to be derated by 4% for

each 1,000 feet of elevation. This equates to 16% or

less than the sea level rating of 270,000 Btu/h.

1. Determine unit input rating:

[270k x (100-16)%] = 226,800 Btuh. The required

heating rate for 3,890 feet is 226,800 Btu/h.

2. Determine orifice size:

From Table 9 (page 34), find the Unit Model Number.

Follow across the row and stop at the 2,000-4,000

elevation column. For this example, the orifice size

displayed is #31. Install one #31 orifice in every burner

and check firing rate. In this example, the firing rate

must not exceed 226,800 Btu/h.

In the U.S., if installing the unit above 2,000 ft., refer to

Table 10 (page 34) to determine the correct orifice size.

When conversion is complete, verify the input rate is correct

as listed in the table.

Please follow the instructions

provided with each kit.

• The United States LP/Propane Gas Sea Level and High

Altitude Conversion Kit is for LP/propane conversion

in the United States at altitudes between 2,000 ft. and

7,000 ft. above sea level.

• The Canadian LP/Propane Gas Sea Level and High

Altitude Conversion Kit is for LP/propane conversions

in Canada at altitudes between zero and 4,500 ft. above

sea level.