Component functions, Troubleshooting – Reznor R6GN Unit Installation Manual User Manual

Page 22

22

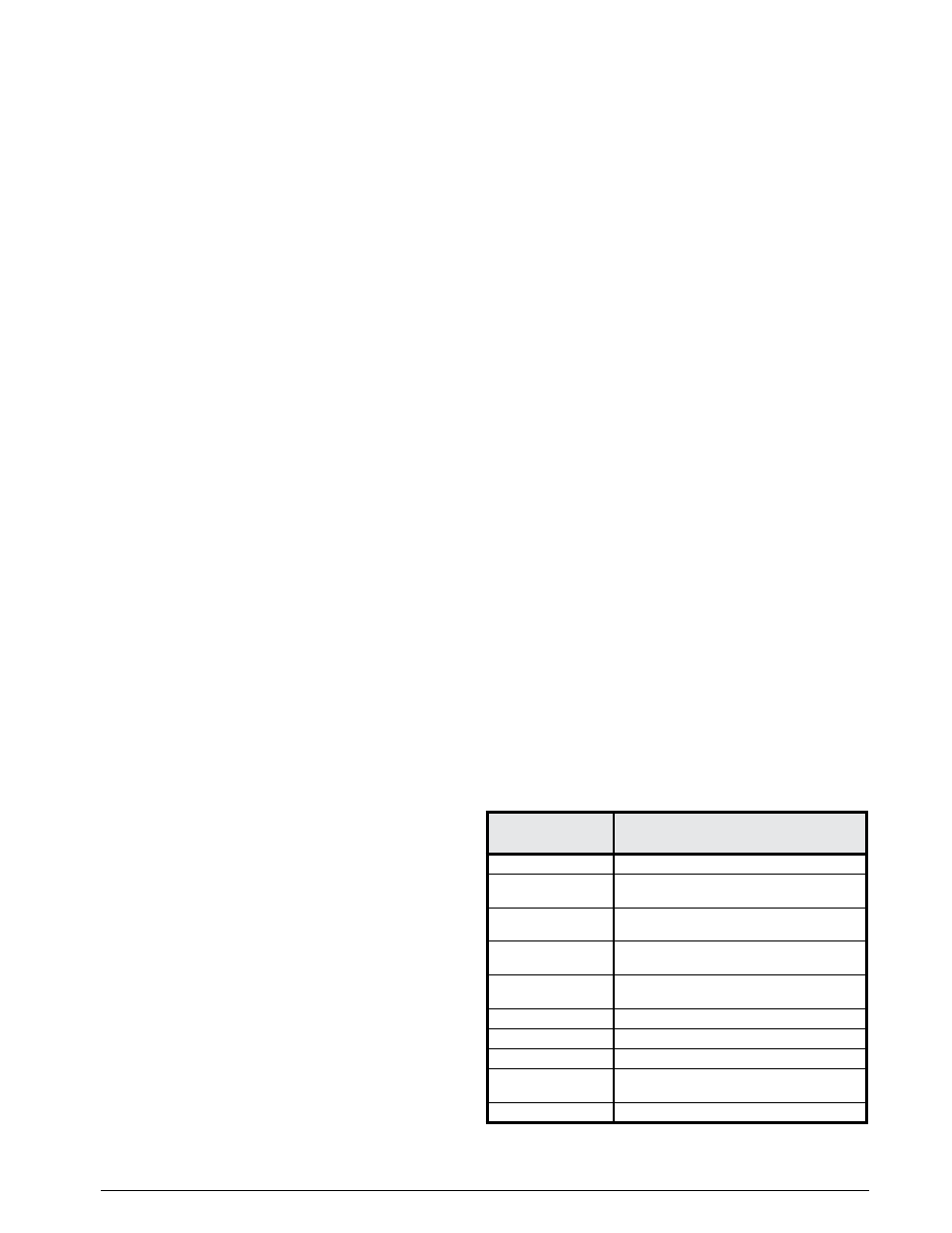

Table 2. Diagnostic Codes

StatuS lIGHt

(Red LED)

Fault

coNDItIoN

Continuous ON

Operation Normal

2 Flashes

Pressure/centrifugal switch open

with inducer on

3 Flashes

Pressure/centrifugal switch closed

with inducer off

4 Flashes

Lockout from too many

failed ignition tries

5 Flashes

Lockout from too many

flame losses

6 Flashes

High temperature switch open

7 Flashes

Rollout switch open

8 Flashes

Flame present with gas off

9 Flashes

Exceeded max limit trips (5)

in one call for heat

10 Flashes

Gas valve fault

Refrigerant High Pressure Switch - This factory installed

switch is designed to de-energize the unit when excessive

pressure occurs due to abnormal conditions. Under normal

conditions, the switch is closed. If the discharge pressure

rises above 650 psig, then the switch will open and de-

energize the outdoor unit. The switch is a manually reset

type and will remain open until the button on top of the

switch is depressed.

Upper Secondary Over-Temperature Limit - The upper

secondary limit control acts to prevent the unit from

operating in case the indoor airflow is disrupted for any

reason. (example: Indoor motor failure, broken belt, etc).

If the limit opens, the 24V input signal to the L terminal of

the blower time delay relay is lost. The relay switches to

Normally Closed (NC) and remains in that position until

the limit closes. The upper secondary limit is located on the

blower deck side panel, opposite end to the motor drive,

and can be accessed through the blower/heat exchanger

access panel for inspection or service.

coMPoNENt FuNctIoNS

The descriptions below are various functional components

that affect the operation and shutting down of this unit.

Some of these components and their locations are shown in

Figure 11 (page 23). If any component on this unit must be

replaced, use only Nordyne authorized replacement parts

specified in the Replacement Parts List provided online.

Flame Roll-Out Control - The flame roll-out control acts

to verify that the burner flame is being drawn into the heat

exchanger tubes. If the burner flame is not being drawn

into the heat exchanger tubes, the roll-out control will

open within several seconds. The combustion blower will

continue to operate if the flame roll-out control opens until

it is manually reset.

Flame Sensor - The flame sensor acts to prove that flame

has carried over from the ignitor to the right-most burner. If

no flame is sensed, the unit will be shut down automatically

and attempt fourteen additional ignition trials before going

into lockout. Recovery from lockout requires a manual

reset by either resetting the thermostat or removing 24

volts for a period of 5 seconds. If the thermostat is still

calling for heat after one hour the control will automatically

reset and attempt to ignite the burner again.

Gas Valve - The gas valve controls the flow of gas to

the burners in both low and high fire. When the valve is

energized, it automatically opens and regulates the gas

pressure to the manifold.

Inducer Motor Pressure Switch - This pressure switch

acts to verify that the inducer motor is running. Combustion

gases are drawn through the heat exchanger tubes and

vented through the vent system.

Indoor Coil Freeze Protection Thermostats - The freeze

protection switches are designed to protect the indoor

coils from ice and frost accumulations in the event of a

loss of airflow by preventing the liquid refrigerant from

reaching the compressors. During normal operation, the

switches are closed and will open if the coil temperature

reaches 28° F (-2° C). The switches will close if the coil

temperature reaches 57° F (12° C).

Over-Temperature Limit Control - The over-temperature

limit control acts to prevent the air temperature leaving the

unit from exceeding the maximum outlet air temperature.

If the limit opens, the 24V input signal to the L terminal of

the blower time delay relay is lost. The relay switches to

Normally Closed (NC) and remains in that position until

the limit closes. The over-temperature limit is located

beneath the heat exchanger tubes (hairpin end) and can

be accessed through the blower/heat exchanger access

panel for inspection or service.

Refrigerant Low Pressure Switch - This factory installed

switch is designed to protect the compressor from a loss

of charge. Under normal conditions, the switch is closed.

If the suction pressure falls below 5 psig, then the switch

will open and de-energize the outdoor unit. The switch

will close again once the suction pressure increases

above 20 psig.

tRouBlESHootING

If the unit does not operate properly in the cooling mode,

check the following:

• The thermostat is operating properly.

• Electrical power to the unit is turned on.

• All safety switches are closed.

• The service doors are in place.

• Transformer circuit breaker is reset.

If the unit does not operate properly in the heating mode,

check the following:

• The thermostat is operating properly.

• Electrical power to the unit is turned on.

• All safety switches are closed.

• The gas is on and shut-off valve is open.

• The service doors are in place.

• The flame roll-out control is closed.

• Refer to the diagnostic codes in Table 2 below or the

wiring diagram (Figure 15, page 30).

• Transformer circuit breaker is reset.