Carrier 19XRV User Manual

Page 16

16

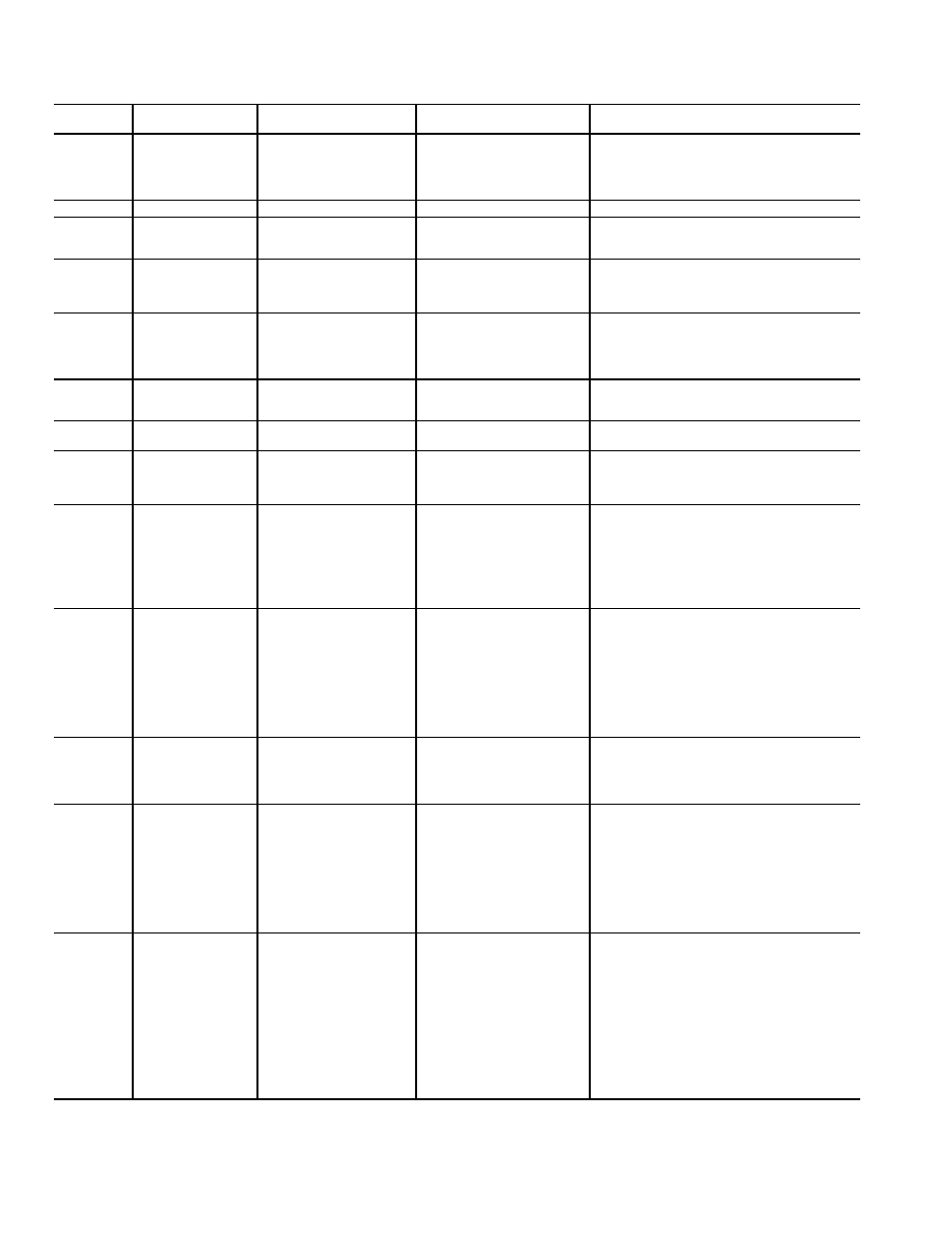

Table 5 — ICVC Alarm Codes (cont)

CHILLER PROTECTIVE LIMIT FAULTS (cont)

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

ICVC FAULT

STATE

PRIMARY

MESSAGE

SECONDARY

MESSAGE

PRIMARY CAUSE

ADDITIONAL CAUSE/REMEDY

220

PROTECTIVE LIMIT GROUND FAULT

220

Ground Fault Trip;

Check Motor and Current

Sensors.

Check for condensation on motor terminals.

Check motor power leads for phase to phase or

phase to ground shorts. Disconnect motor from

VFD and megger motor.

Call Carrier Service.

221

PROTECTIVE LIMIT UNUSED

221

UNUSED

222

PROTECTIVE LIMIT LINE FREQUENCY TRIP

222

Line Frequency —

[VALUE] exceeded limit of

[LIMIT]; Check Power Supply.

If operating from a generator, check generator

size and speed.

Check utility power supply.

223

LOSS OF

COMMUNICATION

WITH VFD GATEWAY

MODULE

223

Loss of SIO Comm with

VFD Gateway: Check VFG

Module and Power.

Check VFD communication wiring and

connectors on VFD Gateway and DPI board.

Check for compatibility between ICVC and

Gateway software.

224

PROTECTIVE LIMIT VFD COMMUNICATIONS

FAULT

224

Loss of DPI Comm with

VFD Gateway: Check VFG to

VFD Comm.

Check VFD communication wiring and

connectors.

Check status lights on DPI Communications

Interface Board.

Call Carrier Service.

225

PROTECTIVE LIMIT MOTOR CURRENT

IMBALANCE

225

Motor Current Imbal-

ance: Check VFD Fault

History for Values.

Check Motor Current % Imbalance in

VFD_CONF screen.

226

PROTECTIVE LIMIT LINE PHASE REVERSAL

226

Line Phase Reversal:

Check Line Phases.

Reverse connections of any two line conductors

to circuit breaker.

227

PROTECTIVE LIMIT OIL PRESS SENSOR

FAULT

227

Oil Pressure Delta P

[VALUE] (Pump Off): Check

Pump/Transducers.

Check transducer wiring and accuracy.

Check power supply to pump.

Check pump operation.

Check transducer calibration.

228

PROTECTIVE LIMIT LOW OIL PRESSURE

228

Low Operating Oil

Pressure [VALUE]: Check Oil

Pump and Filter.

Check transducer wiring and accuracy.

Check power supply to pump.

Check pump operation.

Check oil level.

Check for partially closed service valves.

Check oil filters.

Check for foaming oil at start-up.

Check transducer calibration.

229

PROTECTIVE LIMIT LOW CHILLED WATER

FLOW

229

Low Chilled Water Flow;

Check Switch/Delta P Config

& Calibration.

Perform pump control test.

Check optional transducer calibration and

wiring.

Check Evaporator Refrigerant Temperature

sensor.

Check chilled water valves.

Check for evaporator saturation temperature

< 34 F if not in Pumpdown Lockout mode. Place

unit in Pumpdown mode before removing

charge.

230

PROTECTIVE LIMIT LOW CONDENSER

WATER FLOW

230

Low Condenser Water

Flow; Check Switch/Delta P

Config & Calibration.

Perform pump control test.

Check optional transducer calibration and

wiring.

Check condenser water valves.

Check for COND PRESS OVERRIDE + 5 psig.

231

PROTECTIVE LIMIT HIGH DISCHARGE TEMP

231

Comp Discharge Temp

[VALUE] Exceeded Limit of

[LIMIT]*.

Check for closed compressor discharge isola-

tion valve.

Check if chiller was operating in surge.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for proper condenser flow and

temperature.

Check compressor discharge isolation valve.

Check for proper inlet guide vane and optional

diffuser actuator operation.

232

PROTECTIVE LIMIT LOW REFRIGERANT

TEMP

232

Evaporator Refrig Temp

[VALUE] exceeded limit of

[LIMIT]*.

Check for proper refrigerant charge.

Check float valve operation.

Check for closed condenser liquid line isolation

valve. If problem occurs at high load, check for

low condenser pressure which causes inade-

quate flasc orifice differential pressure.

Check for proper water flow and temperature.

Confirm that condenser water enters bottom row

of condenser tubes first.

Check Evaporator Refrigerant Temperature

sensor.

Check for division plate gasket bypass.

Check for fouled tubes.