Carrier 19XRV User Manual

Page 13

13

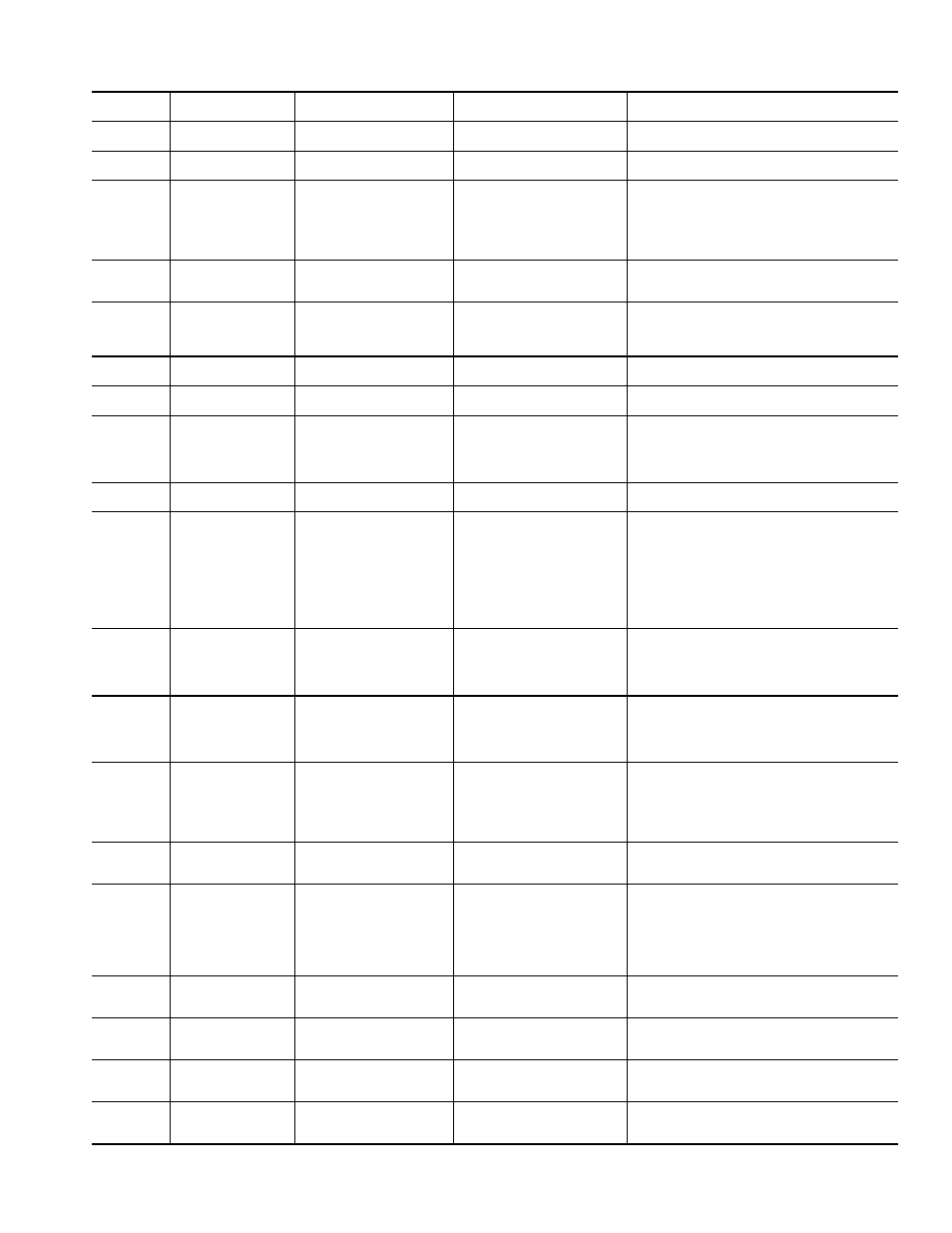

Table 4 — ICVC Alert Codes (cont)

CHILLER ALERTS

*[LIMIT] is shown on the ICVC as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

ICVC FAULT

STATE

PRIMARY

MESSAGE

SECONDARY

MESSAGE

PRIMARY CAUSE

ADDITIONAL CAUSE/REMEDY

140

SENSOR ALERT

LEAVING COND WATER

TEMP

140

Sensor Fault: Check

Leaving Cond Water Sensor.

Check sensor resistance or voltage drop.

Check for proper wiring.

141

SENSOR ALERT

ENTERING COND WATER

TEMP

141

Sensor Fault: Check

Entering Cond Water Sensor.

Check sensor resistance or voltage drop.

Check for proper wiring.

142

LOW OIL

PRESSURE ALERT

CHECK OIL FILTER

142

Low Oil Pressure Alert.

Check Oil Filter.

Check for partially or closed shut-off valves.

Check oil filter.

Check oil pump and power supply.

Check oil level.

Check for foaming oil at start-up.

Check transducer wiring and accuracy.

143

AUTORESTART

PENDING

LINE CURRENT

IMBALANCE

143

Line Current Imbal-

ance: Check VFD Fault His-

tory for Values.

Power loss has been detected in any phase.

Chiller automatically restarting.

144

AUTORESTART

PENDING

LINE VOLTAGE

DROP OUT

144

Single Cycle Line

Voltage Dropout.

A drop in line voltage has been detected within

2 voltage cycles.

Chiller automatically restarting if Auto Restart is

enabled in OPTIONS screen.

145

AUTORESTART

PENDING

HIGH LINE VOLTAGE

145

High Percent Line

Voltage [VALUE].

Check phase to phase and phase to ground line

power.

146

AUTORESTART

PENDING

LOW LINE VOLTAGE

146

Low Percent Line

Voltage [VALUE].

Check phase to phase and phase to ground line

power.

147

AUTORESTART

PENDING

VFD MODULE RESET

147->VFD Module Power-On

Reset When Running.

VFD Module has detected a hardware fault due

to electrical noise, power loss or software and

has reset. Chiller automatically restarting.

Check for power loss and sources of electro-

magnetic interference.

148

AUTORESTART

PENDING

POWER LOSS

148

Control Power-Loss

When Running.

Check 24 vac control power supply to ICVC.

149

SENSOR ALERT

HIGH DISCHARGE TEMP

149

Comp Discharge Temp

[VALUE] Exceeded Limit of

[LIMIT]*.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for proper inlet guide vane and optional

diffuser actuator operation.

Check for proper condenser flow and

temperature.

Check for high lift or low load.

Check for fouled tubes or noncondensables in

the chiller.

150

SENSOR ALERT

HIGH BEARING

TEMPERATURE

150

Comp Thrust Brg Temp

[VALUE] exceeded limit of

[LIMIT]*.

Check sensor resistance or voltage drop.

Check for proper wiring.

Check for partially closed service valves.

Check oil cooler TXV.

Check oil level and oil temperature.

151

CONDENSER

PRESSURE ALERT

PUMP RELAY

ENERGIZED

151

High Condenser Pres-

sure [VALUE]: Pump Ener-

gized to Reduce Pressure.

Check sensor wiring and accuracy.

Check condenser flow and water temperature.

Check for fouled tubes.

This alarm is not caused by the High Pressure

Switch.

152

RECYCLE ALERT

EXCESSIVE RECYCLE

STARTS

152

Excessive recycle

starts.

Chiller load is too low to keep compressor on

line and there has been more than 5 starts in

4 hours.

Increase chiller load, adjust hot gas bypass,

increase RECYCLE RESTART DELTA T from

SETUP1 Screen.

153

no message:

ALERT

only

no message; ALERT only

153

Lead/Lag Disabled-

Config: Duplicate Chiller

Address.

Illegal chiller address configuration in Lead/Lag

screen. Both chillers require a different address.

154

POTENTIAL

FREEZE-UP

COND PRESS/TEMP

TOO LOW

154

Condenser freeze up

prevention.

The condenser pressure transducer is reading a

pressure that could freeze the condenser tubes.

Check for condenser refrigerant leaks.

Check fluid temperature.

Check sensor wiring and accuracy.

Place the chiller in PUMPDOWN mode if the

vessel is evacuated.

155

OPTION SENSOR

FAULT

REMOTE RESET

SENSOR

155

Sensor Fault/Option

Disabled: Remote Reset

Sensor.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J4.

156

OPTION SENSOR

FAULT

AUTO CHILLED WATER

RESET

156

Sensor Fault/Option

Disabled: Auto Chilled Water

Reset.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J5.

157

OPTION SENSOR

FAULT

AUTO DEMAND LIMIT

INPUT

157

Sensor Fault/Option

Disabled: Auto Demand Limit

Input.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J5.

158

SENSOR ALERT

SPARE TEMPERATURE

#1

158

Spare Temperature 1

[VALUE] exceeded limit of

[LIMIT]*.

Check sensor resistance or voltage drop.

Check for proper wiring to CCM connector J4.

Check Spare Temp #1 Limit in SETUP1 screen.