Warning – Carrier V2203-DI (26--00128) User Manual

Page 67

62--11362

5--3

5.2

INJECTION NOZZLE

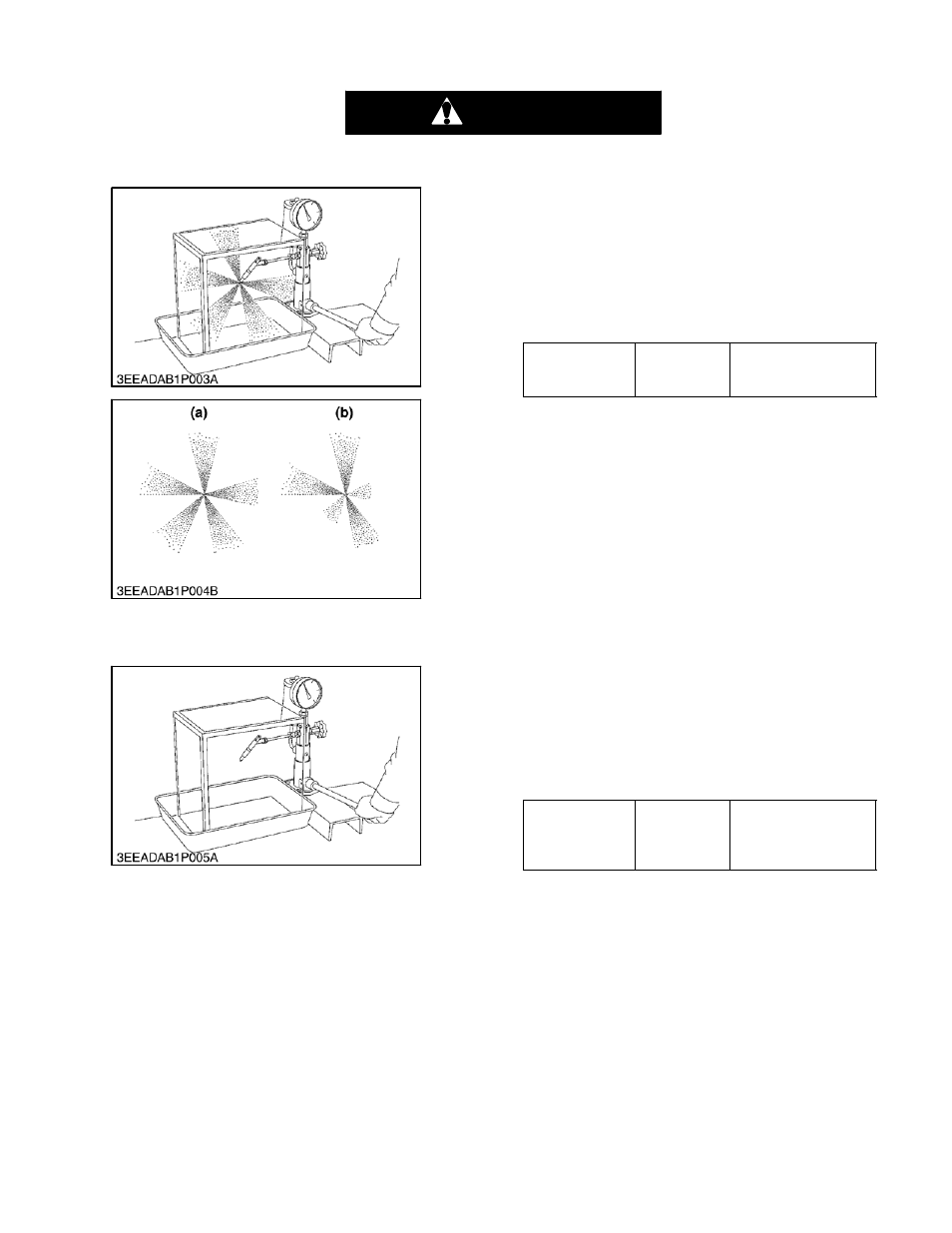

WARNING

Check the injection nozzle only after confirming that nobody is near the spray. If the spray from the

nozzle contacts the human body, cells may be destroyed and blood poisoning may result.

(a) GOOD

(b) BAD

5.2.1 Nozzle Injection Pressure

1. Set the injection nozzle in a nozzle tester.

2. Slowly move the tester handle to measure the pres-

sure at which fuel begins jetting out from the nozzle.

3. If the measurement is not within factory specifica-

tions, replace the nozzle assembly.

Fuel Injection

Pressure

1st Stage

Factory

Specification

18.64 to 20.1 MPa

190 to 205 kgt/cm

2

2703 to 2915 psi

5.2.2 Nozzle Spraying Condition

1. Set the injection nozzle in a nozzle tester and check

the nozzle spraying condition.

2. If the spraying condition is defective, replace the

injection nozzle assembly.

5.2.3 Valve Seat Tightness

1. Set the injection nozzle in a nozzle tester.

2. Raise the fuel pressure, and maintain 16.67 MPa

(170 kgf/cm

2

, 2418 psi) for 10 seconds.

3. If any fuel leak is found, replace the injection nozzle

assembly.

Valve Seat Tight-

ness

Factory

Specification

No fuel leak at

16.67MPa

170 kgf/cm

2

2418 psi