Carrier V2203-DI (26--00128) User Manual

Page 48

2--22

62--11362

2.3.1 Cylinder Head And Valves (Continued)

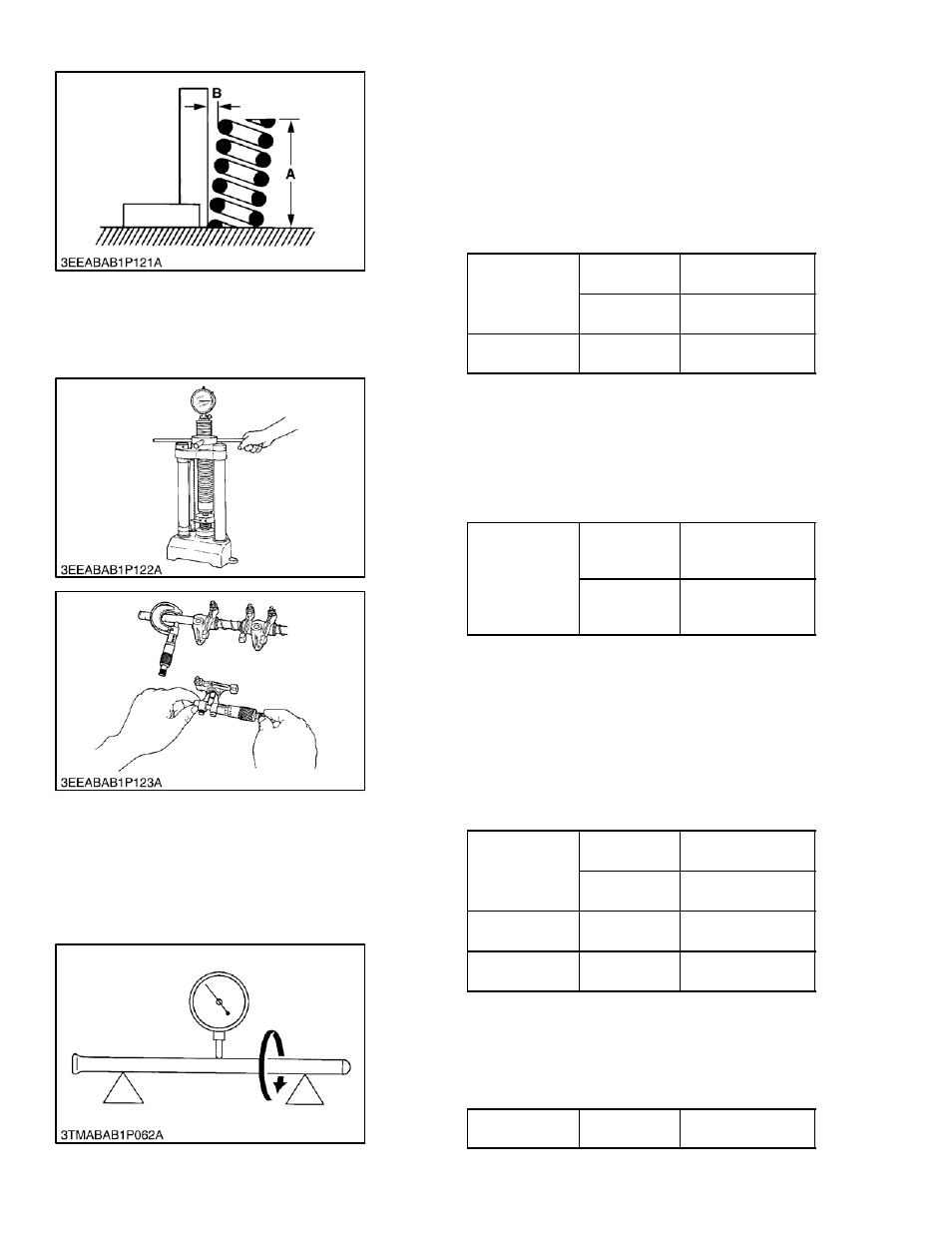

2.3.1.i Free Length and Tilt of Valve Spring

1. Measure the free length A of the valve spring with ver-

nier calipers. If the measurement is less than the al-

lowable limit, replace the spring.

2. Put the valve spring on a surface plate, place a

square on the side of the valve spring.

3. Check to see if the entire side is in contact with the

square. Rotate the spring and measure for maximum

tilt B. Check the entire surface of the valve spring for

defects. If any are found, replace it.

Free Length A

Factory

Specification

41.7 to 42.2 mm

1.65 to 1.66 in.

Allowable Limit

41.2 mm

1.62 in.

Tilt B

Allowable Limit

1.0 mm

0.039 in.

2.3.1.j Valve Spring Setting Load

1. Place the valve spring on a tester and compress it to

the same length it is actually compressed in the en-

gine.

2. Read the compression load on the gauge.

3. If the measurement is less than the allowable limit, re-

place it.

Setting Load /

Setting Length

Factory

Specification

118 N / 35 mm

12.0 kgf / 35 mm.

26.5 lbs. / 1.38 in.

Allowable

Limit

100 N / 35 mm

10.2 kgf / 35 mm.

22.5 lbs. / 1.38 in.

2.3.1.k Oil Clearance Between Rocker Arm and

Rocker Arm Shaft

1. Measure the rocker arm shaft O.D. with an outside

micrometer.

2. Measure the rocker arm I.D. with a inside micrometer,

then calculate the oil clearance.

3. If the oil clearance exceeds the allowable limit, re-

place the rocker arm then measure the oil clearance

again. If the clearance is still out of specification, re-

place the rocker arm shaft.

Oil Clearance

Rocker Arm/

Shaft

Factory

Specification

0.016 to 0.045 mm

0.0063 to 0.0017 in.

Allowable

Limit

0.10 mm

0.0039 in.

Rocker Arm

Shaft O.D.

Factory

Specification

13.973 to 13.984 mm

0.55012 to 0.55055 in.

Rocker Arm I.D.

Factory

Specification

14.000 to 14.018 mm

0.55119 to 0.55188 in.

2.3.1.l Push Rod Alignment

1. Place the push rod on V blocks

2. Measure the push rod alignment.

3. If the measurement exceeds the allowable limit, re-

place the push rod.

Push Rod

Alignment

Allowable

Limit

0.25 mm

0.0098 in.