Carrier V2203-DI (26--00128) User Manual

Page 55

2--29

62--11362

2.3.4 Crankshaft (Continued)

2.3.4.c Crankpin to Connecting Rod Bearing Clear-

ance

1. Clean the crankpin and the connecting rod bearing.

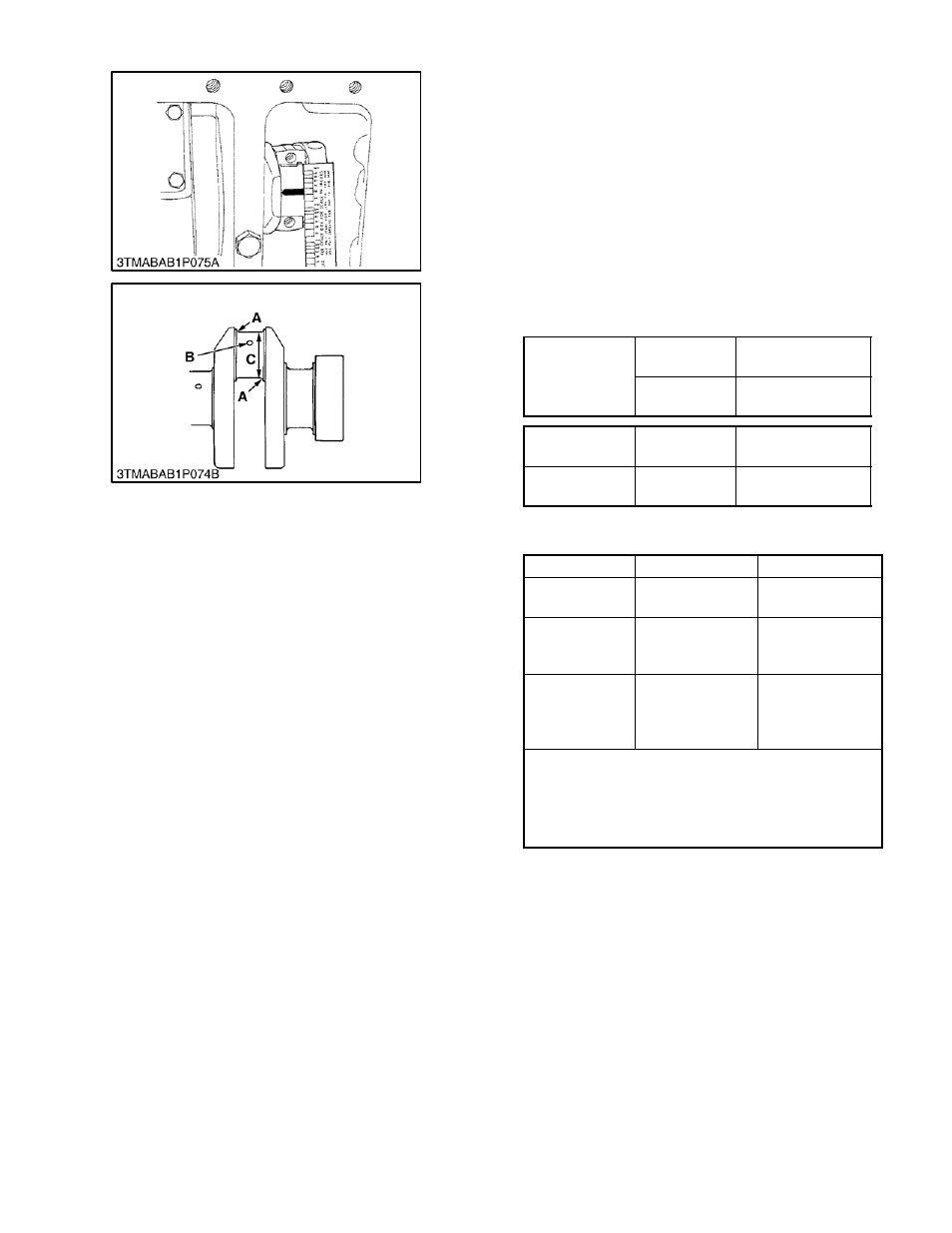

2. Put a strip of plastigage on the center of the crankpin

in each direction as shown in the figure.

3. Install the connecting rod cap and tighten the bolts to

the specification. (Refer to 2.2.6.a)

4. Remove the cap again

5. Measure the amount of the flattening with the scale to

get the clearance.

6. If the measurement exceeds the allowable limit re-

place the connecting rod bearing.

7. If the allowable limit is not attainable with a standard

size bearing, install an undersize bearing by referring

to the table below.

Crankpin/

Connecting Rod

Clearance

Factory

Specification

0.025 to 0.087 mm

0.00099 to 0.0034 in.

Allowable

Limit

0.2 mm

0.0079 in.

Crankpin O.D.

Factory

Specification

46.959 to 46.975 mm

1.8488 to 1.8494 in.

Connecting Rod

Bearing I.D.

Factory

Specification

47.000 to 47.046 mm

1.8504 to 1.8522 in.

(Reference)

Undersize dimensions of crankpin journal.

Undersize

0.2mm / 0.008 in.

0.4mm / 0.02 in.

Dimension A

3.3 to 3.7 mm

0.13 to 0.14 in.

3.3 to 3.7 mm

0.13 to 0.14 in.

Dimension B

1.0 to 1.5 mm radius

0.040 to 0.059 in.

radius

1.0 to 1.5 mm radius

0.040 to 0.059 in.

radius

Dimension C

46.759 to 46.775

mm

1.8409 to 1.8415 in.

radius

46.559 to 46.575

mm

1.8331 to 1.8336 in.

radius

The crankshaft journal must be fine--finished to higher than

0.8--S.

*

Holes to be de---burred and edges rounded with 1.0 to 1.5

mm

(0.040 to 0.059 in. relief.