Carrier V2203-DI (26--00128) User Manual

Page 39

2--13

62--11362

2.2.6 Piston and Connecting Rod

6

2.2.6.a Pistons

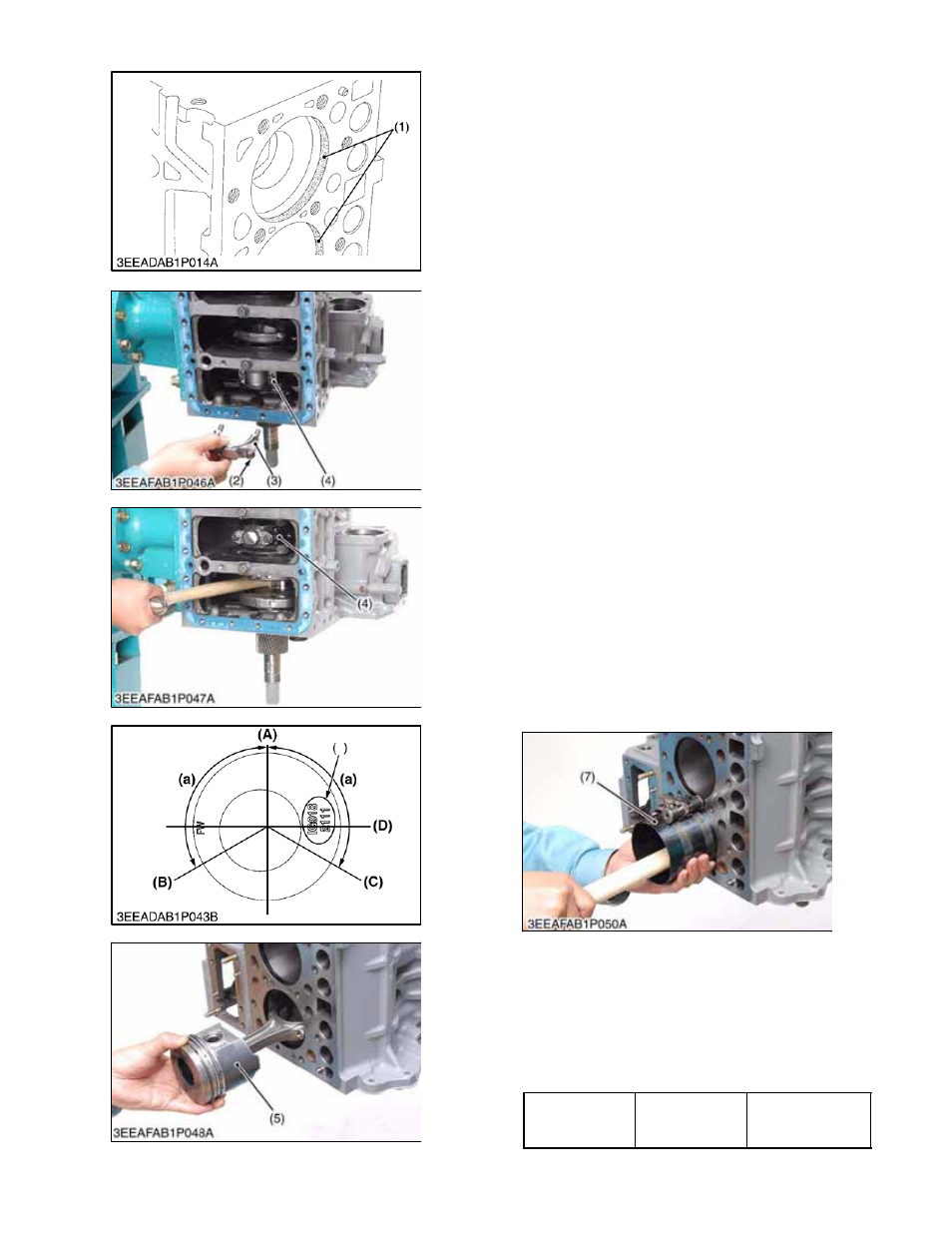

1. Completely remove the carbon ridge (1) at the top of

the cylinder walls.

2. Remove the connecting rod cap (3).

3. Turn the flywheel and bring the piston to top dead

center.

4. Push the piston out by lightly tapping the connecting

rod from the bottom of the crankcase with the grip of a

hammer.

5. Repeat the procedure for the other three cylinders.

When Reassembling

Liberally coat the piston and piston rings with engine oil.

When inserting the piston into the cylinder, face the

mark on the connecting rod to the injection pump.

NOTE

If re--installing the original piston assemblies

into the engine be sure that they are returned to

their original cylinder.

Place the piston rings with their gaps at 2.09

rad. (120

°

) from the piston pin’s direction as

shown.

Carefully insert the pistons into the cylinders

using the piston ring compressor (7).

When inserting the piston into the cylinder avoid

damaging the molybdenum disulfide coating on

the piston skirt. This coating is useful in mini-

mizing the clearance between the piston and

cylinder.

When replacing a piston, use a replacement

piston with the same code number. The piston

ID mark (6) is on top of the piston.

1. Carbon

2. Connecting Rod Bolt

3. Connecting Rod Cap

4. Connecting Rod

5. Molybdenum Disulfide

Coating on Piston Skirt

6. Piston ID Mark

7. Piston Ring Compressor

(A) Top Ring Gap

(B) Second Ring Gap

(C) Oil Ring Gap

(D) Piston Pin Hole

(a)

2.09 rad. (120

°

)

Tightening

Torque

Connecting

Rod Bolt

45 to 49 N

.

m

4.5 to 5.0 kgf

.

m

33 to 36 ft--lbs