Carrier V2203-DI (26--00128) User Manual

Page 57

2--31

62--11362

2.3.4 Crankshaft (Continued)

2.3.4.f Crankshaft Journal to Crankshaft Bearing

#2 Clearance

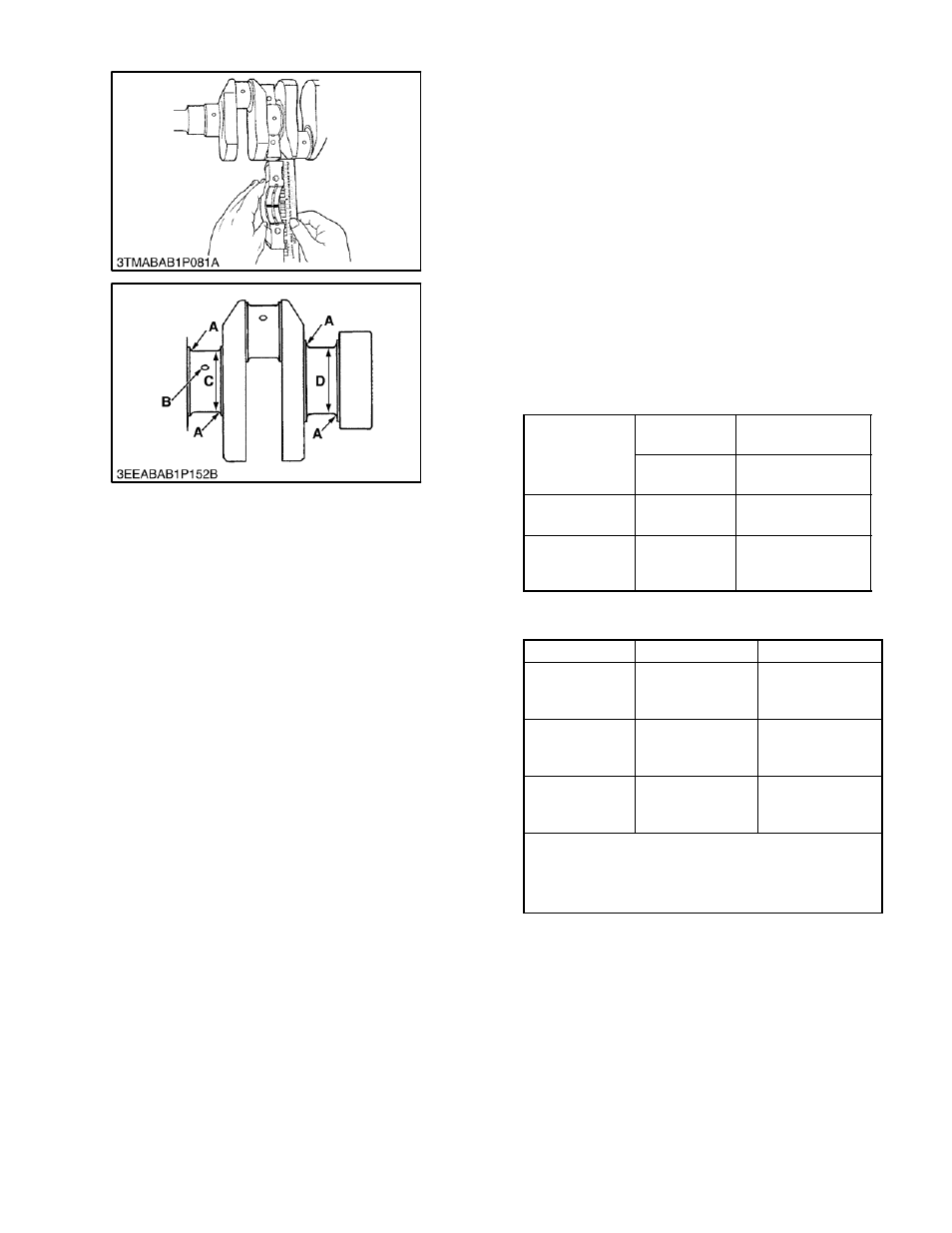

1. Put a strip of plastigage on the center of the crank-

shaft journal.

2. Install the bearing case and tighten the bolts to spe-

cification.

3. Remove the bearing case again.

4. Measure the amount of the flattening with the scale to

get the clearance.

5. If the measurement exceeds the allowable limit re-

place crankshaft bearing #2.

6. If the allowable limit is not attainable with a standard

size bearing, install an undersize bearing by referring

to the table below.

NOTE

Be sure not to move the crankshaft while the

bearing bolts are tightened.

Crankshaft

Journal to #2

Bearing

Clearance

Factory

Specification

0.040 to 0.104 mm

0.00158 to 0.00409 in.

Allowable

Limit

0.2 mm

0.0079 in.

Crankshaft

Journal O.D

.

Factory

Specification

59.921 to 59.940 mm

2.3591 to 2.3598 in.

Crankshaft

Bearing Bearing

I.D.

Factory

Specification

59.980 to 60.025 mm

2.3615 to 2.3631 in.

(Reference)

Undersize dimensions of crankshaft journal.

Oversize

0.2mm / 0.008 in.

0.4mm / 0.016 in.

Dimension A

2.8 to 3.2 mm radius

0.11 to 0.12 in.

radius

2.8 to 3.2 mm radius

0.11 to 0.12 in.

radius

Dimension B

1.0 to 1.5 mm radius

0.040 to 0.059 in.

radius

1.0 to 1.5 mm radius

0.040 to 0.059 in.

radius

Dimension C

59.721 to 59.740

mm

2.3513 to 2.3519 in.

59.521 to 59.540

mm

2.3433 to 2.3440 in.

The crankshaft journal must be fine--finished to higher than

0.4--S.

*Holes to be de--burred and edges rounded with 1.0 to 1.5 mm

(0.040 0.059 in.) relief.