Carrier V2203-DI (26--00128) User Manual

Page 45

2--19

62--11362

2.3.1 Cylinder Head And Valves (Continued)

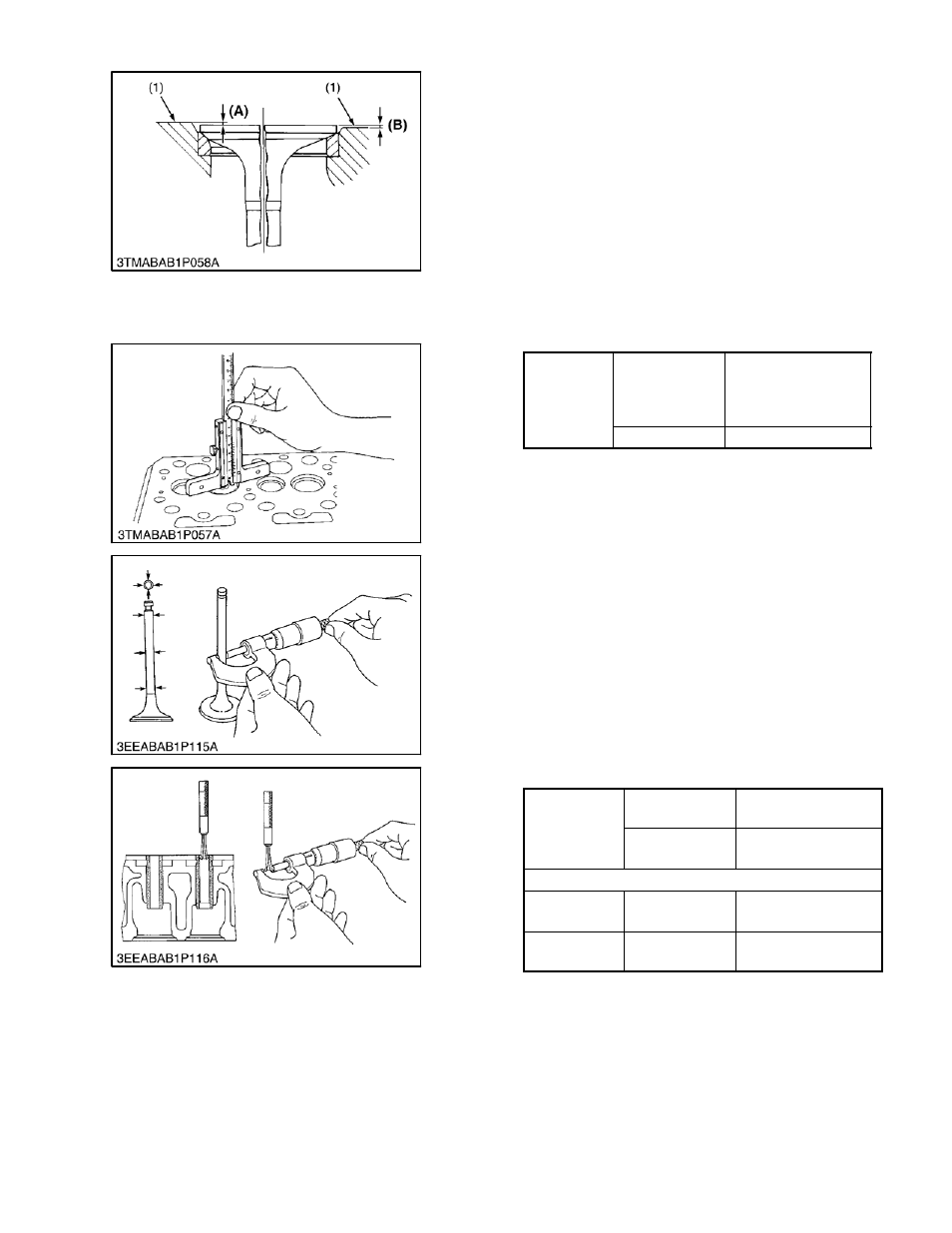

1. Cylinder Head

Surface

(A) Recess

(B) Protrusion

2.3.1.c Valve Recessing

1. Clean the cylinder head surface (1), valve face and

valve seat.

2. Insert the valve into the head, making certain that the

valve is fully seated.

3. Measure the valve recessing with a depth gauge.

4. If the measurement exceeds the allowable limit, re-

place the valve.

5. If the measurement still exceeds the allowable limit,

replace the cylinder head.

Valve

Recessing

Factory

Specification

0.065 (protrusion) mm to

0.085 (recessing) mm

0.026 (protrusion) in. to

0.033 (recessing) in.

Allowable Limit

--

2.3.1.d Clearance Between Valve Stem And Valve

Guide

1. Remove carbon from the valve guide section.

2. Measure the valve stem O.D. with a micrometer.

3. Measure the valve guide with a small hole gauge, and

calculate the clearance.

4. If the clearance exceeds the the allowable limit, re-

place the valves. If the clearance still exceeds the al-

lowable limit, replace the valve guide.

Clearance

Between

Valve Stem

and Guide

Factory

Specification

0.040 to 0.070 mm

0.0016 to 0.0027 in.

Allowable Limit

0.1 mm

0.0039 in.

Valve Stem

O.D.

Factory

Specification

7.960 to 7.975 mm

0.3134 to 0.3139 in.

Valve Guide

I.D.

Factory

Specification

8.015 to 8.030 mm

0.3156 to 0.3161 in.