Carrier V2203-DI (26--00128) User Manual

Page 53

2--27

62--11362

2.3.3 Piston and Connecting Rod (Continued)

2.3.3.d Piston Ring Gap

1. Insert the piston ring into the lower part of the cylinder

(the least worn section). Use the piston to square the

ring in the cylinder.

2. Measure the ring gap with a feeler gauge.

3. If the gap exceeds the allowable limit, replace the

ring.

Top Ring

(Keystone Type)

Factory

Specification

0.20 to 0.35 mm

0.0079 to 0.013 in.

Allowable Limit

1.25 mm / 0.0492 in.

Second Ring

Factory

Specification

0.40 to 0.55 mm

0.016 to 0.021 in.

Allowable Limit

1.25 mm / 0.0492 in.

Oil Control Ring

Factory

Specification

0.25 to 0.45 mm

0.0099 to 0.017 in.

Allowable Limit

1.25 mm / 0.0492 in.

2.3.3.e Piston Ring to Groove Clearance

1. Clean the rings and the ring grooves, and install each

ring in its groove.

2. Measure the clearance between the ring and its

groove with a feeler gauge (with the exception of the

top ring, Keystone Type, which cannot be accurately

measured with a feeler gauge).

3. If the clearance exceeds the allowable limit, replace

the ring.

4. If the clearance still exceeds the allowable limit after

replacing the ring, replace the piston.

Second Ring

Factory

Specification

0.093 to .128 mm

0.00367 to 0.00503 in.

Allowable Limit

0.20 mm / 0.0079 in.

Oil Control Ring

Factory

Specification

0.020 to 0.060 mm

0.00079 to 0.0023 in.

Allowable Limit

0.15 mm / 0.0059 in.

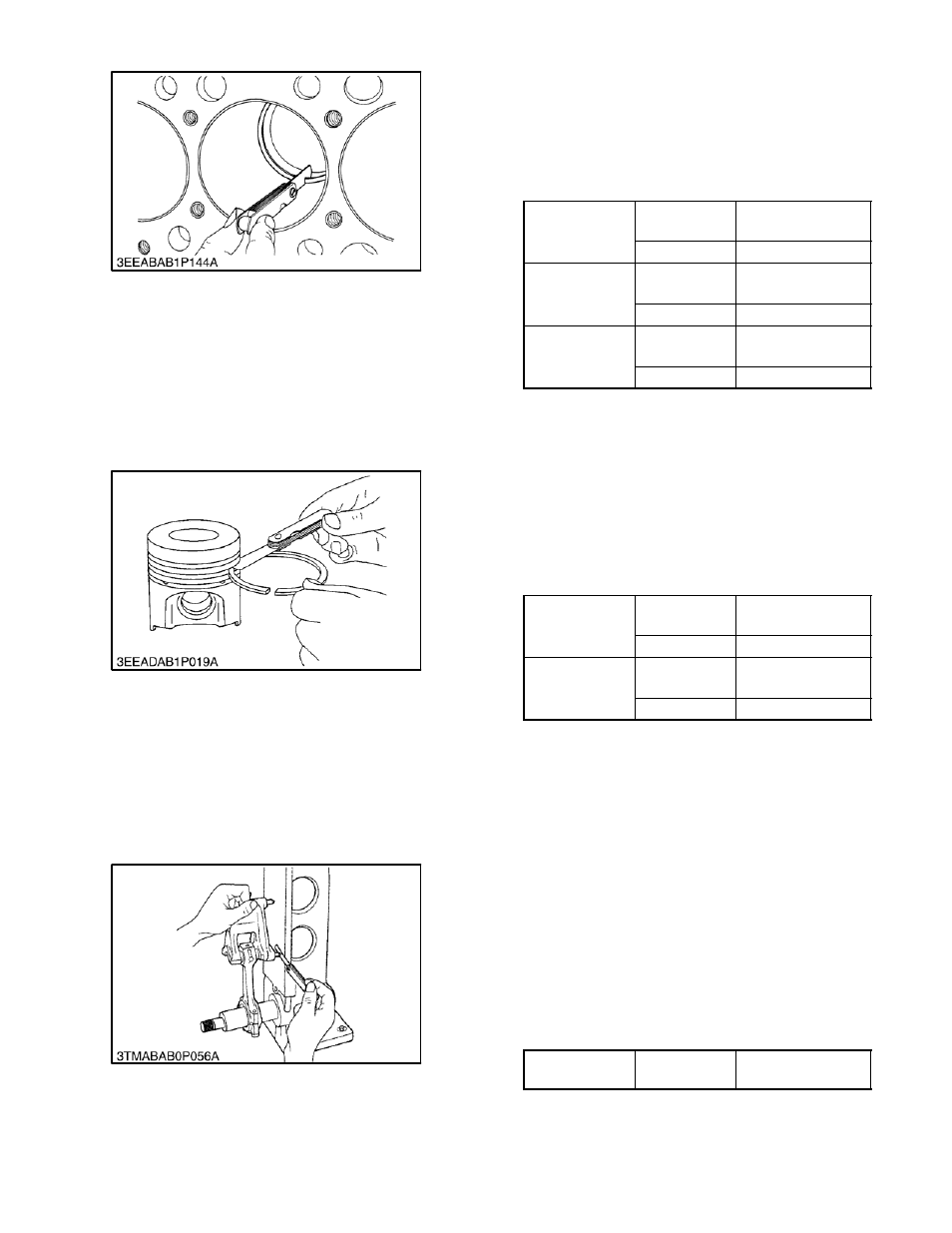

2.3.3.f Connecting Rod Alignment

NOTE

Since the I.D. of the connecting rod small end

bushing is the basis of this procedure, check the

bushing for wear before proceeding.

1. Install the piston pin into the connecting rod.

2. Install the connecting rod on the connecting rod align-

ment tool.

3. Put a gauge over the piston pin and move it against

the face plate.

4. If the gauge does not fit squarely against the face

plate, measure the space between the pin of the

gauge and the face plate.

5. If the measurement exceeds the allowable limit, re-

place the connecting rod.

Connecting Rod

Alignment

Allowable Limit

0.05 mm / 0.002 in.