Carrier V2203-DI (26--00128) User Manual

Page 54

2--28

62--11362

2.3.4 Crankshaft

A

B

2.3.4.a Crankshaft End Clearance

1. Push on the end of the crankshaft to seat it toward the

flywheel end of the engine block.

2. Attach, then zero a dial indicator on the forward end of

the crankshaft.

3. Measure the end play by pulling the crankshaft for-

ward.

4. If the measurement exceeds the allowable limit re-

place the thrustwashers.

Crankshaft Side

Clearance

Factory

Specification

0.15 to 0.31 mm

0.0059 to 0.012 in.

Allowable

Limit

0.5 mm

0.02 in.

(Reference)

Oversize dimensions of crankshaft journal.

Oversize

0.2mm / 0.008 in.

0.4mm / 0.02 in.

Dimension A

54.5 to 54.7 mm

2.146 to 2.153 in.

54.6 to 54.8 mm

2.150 to 2.157 in.

Dimension B

26.20 to 26.25 mm

1.032 to 1.033 in.

26.40 to 26.45 mm

1.040 to 1.041 in.

Dimension C

2.8 to 3.2 mm radius

0.11 to 0.12 in.

radius

2.8 to 3.2 mm radius

0.11 to 0.12 in.

radius

The crankshaft journal must be fine--finished to higher than

0.4--S.

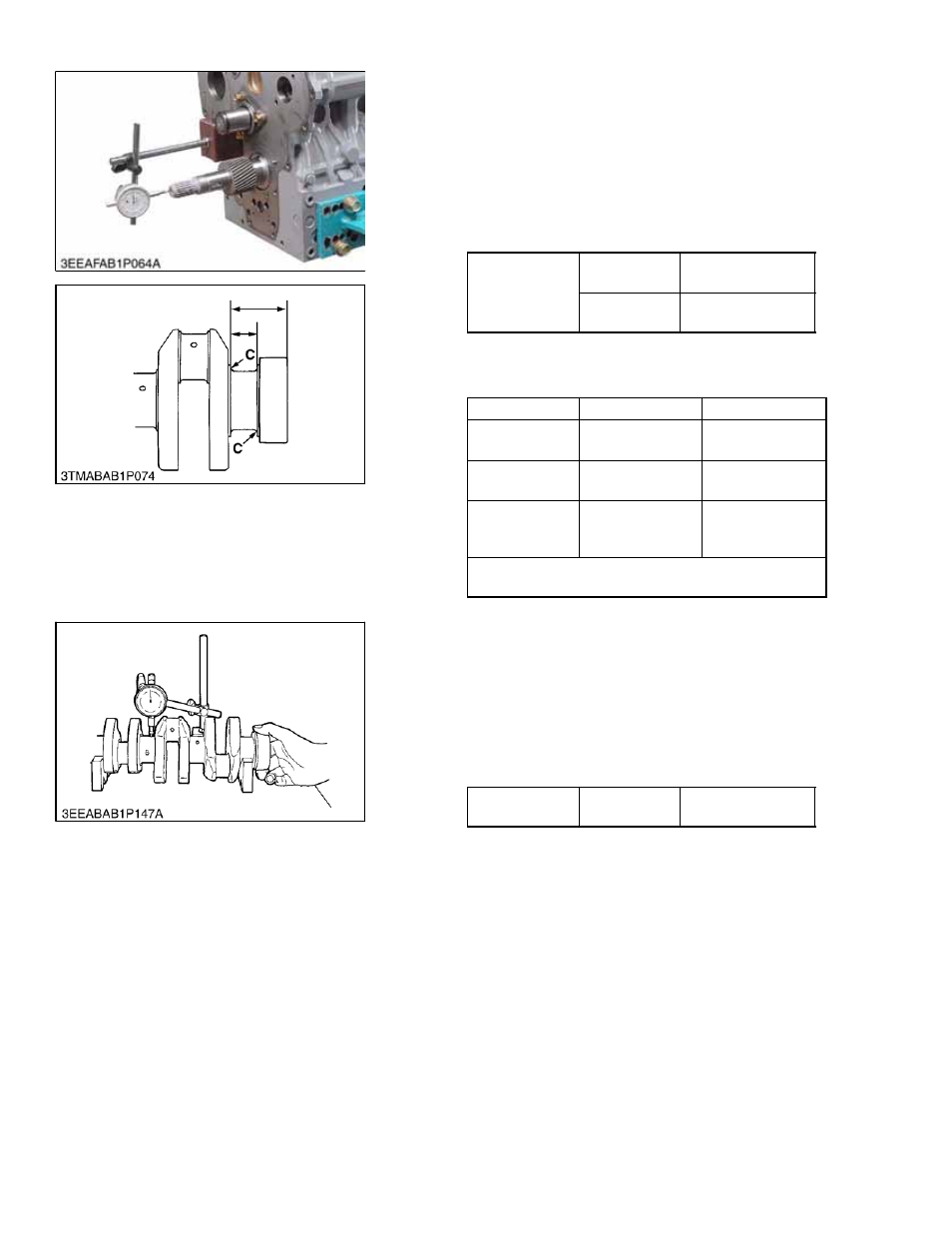

2.3.4.b Crankshaft Alignment

1. Support the crankshaft with V blocks on a surface

plate at both end journals. Set a dial indicator with its

tip on the intermediate journal, perpendicular to the

journal.

2. Rotate the crankshaft on the V blocks and get the

misalignment (half of the measurement).

3. If the misalignment exceeds the allowable limit, re-

place the crankshaft.

Crankshaft

Alignment

Allowable

Limit

0.02 mm

0.0008 in.