Carrier V2203-DI (26--00128) User Manual

Page 44

2--18

62--11362

2.3

SERVICING

2.3.1 Cylinder Head And Valves

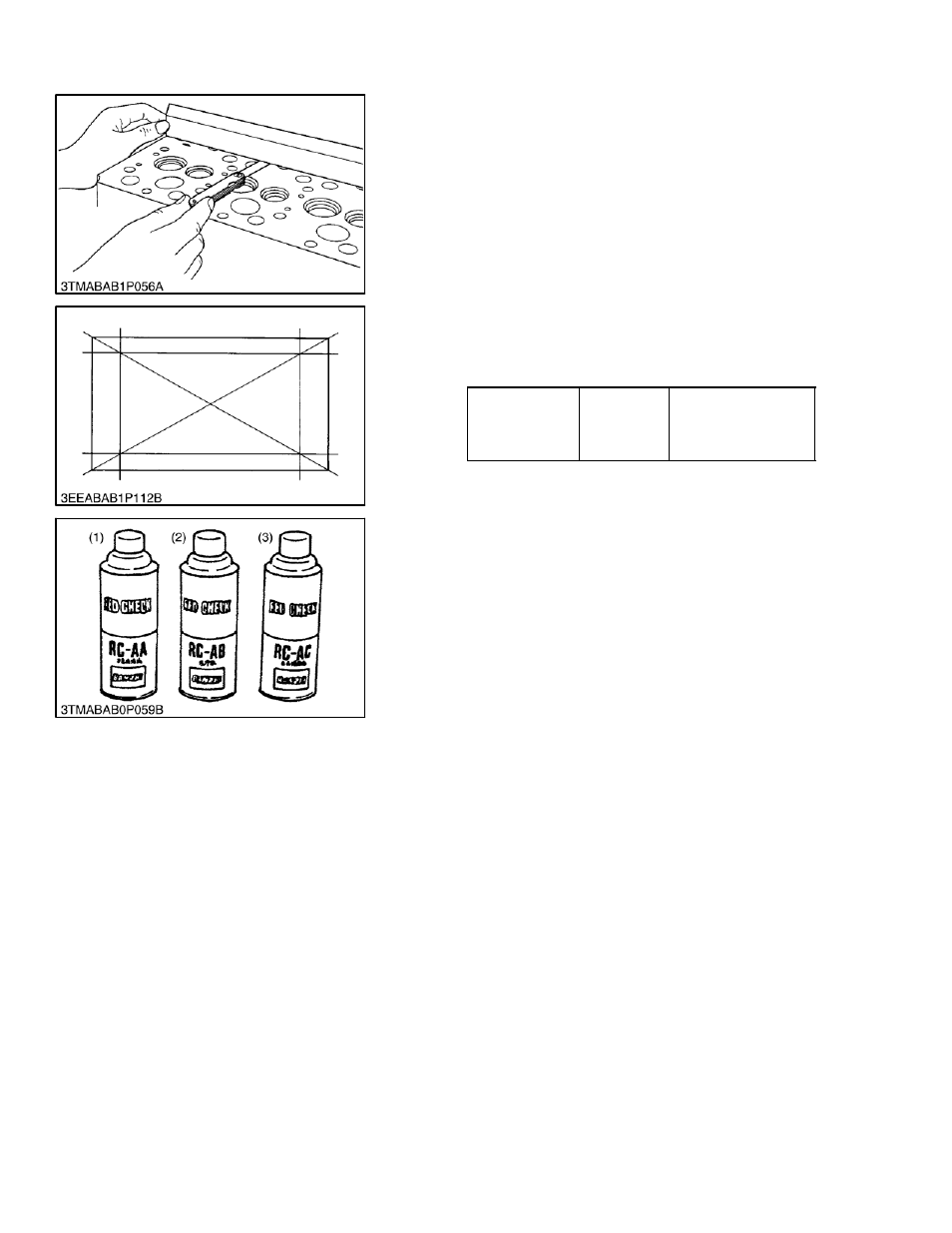

1. Red Dye

2. Detergent

3. White Developer

2.3.1.a Cylinder Head Surface Flatness

1. Clean the cylinder head surface.

2. Place a straightedge on the cylinder head surface, in

six locations as depicted in the drawing.

3. Measure any clearance between the straightedge

and cylinder head with a feeler gauge.

4. If the measurement exceeds the allowable limit,

resurface or replace the head.

NOTE

Check the valve recessing after after resurfac-

ing the head.

Cylinder Head

Surface Flatness

Factory

Specification

0.05mm over a span of

500mm

0.002 in. over a span of

20 in.

2.3.1.b Cylinder Head Cracks

1. Cylinder head crack(s) can be found with using a

non--destructive test procedure using a dye/pene-

trant kit.

2. Clean the cylinder head surface using a good quality

degreaser and detergent (2).

3. Spray the cylinder head surface with the red liquid or

dye (1). Let it sit on the surface for ten minutes.

4. Wash the dye off the head using the detergent (2) and

dry the head.

5. Spray the white developer (3) on to the head.

6. Red marks will bleed through the developer identify-

ing cracks in the head if they are present.