Great Planes Giant Extra 330L Kit - GPMA0250 User Manual

Page 44

After the model is covered, you must fuel-proof all exposed

wood. You may do so with fuel-proof model paint, 30-minute

epoxy thinned with alcohol, or finishing resin.

Top Flite LustreKote

®

fuel-proof paint is recommended for

painting all the parts. (The wheel pants should be removed

from the landing gear prior to painting.) Apply one coat of

LustreKote primer to fill all the small scratches left from

sanding as well as small pin holes in any filler and in the

fiberglass. Wet sand between coats with 400-grit sandpaper

and apply additional coats of primer if necessary. If the parts

are primed properly, a few light coats of color will quickly

provide you with a beautiful match to the MonoKote.

❏ 1. Reinstall the wing and stab anti-rotation dowels, being

sure to center them in the fuse. Glue in place with medium

CA. Note: These dowels take a lot of the load of the plane.

Make sure these are securely glued in place.

❏ 2. Permanently attach the control surfaces. Start with the

elevators and stab. Cut the covering from the hinge slots. Install

your hinges per the manufacturer’s instructions. If you are using

Robart’s Giant Scale Pin Hinges as we did on the prototypes,

we recommend coating the pivot point of the hinge with

petroleum jelly prior to epoxying the hinges in place.

❏ 3. Attach the rudder and ailerons as you did the elevators.

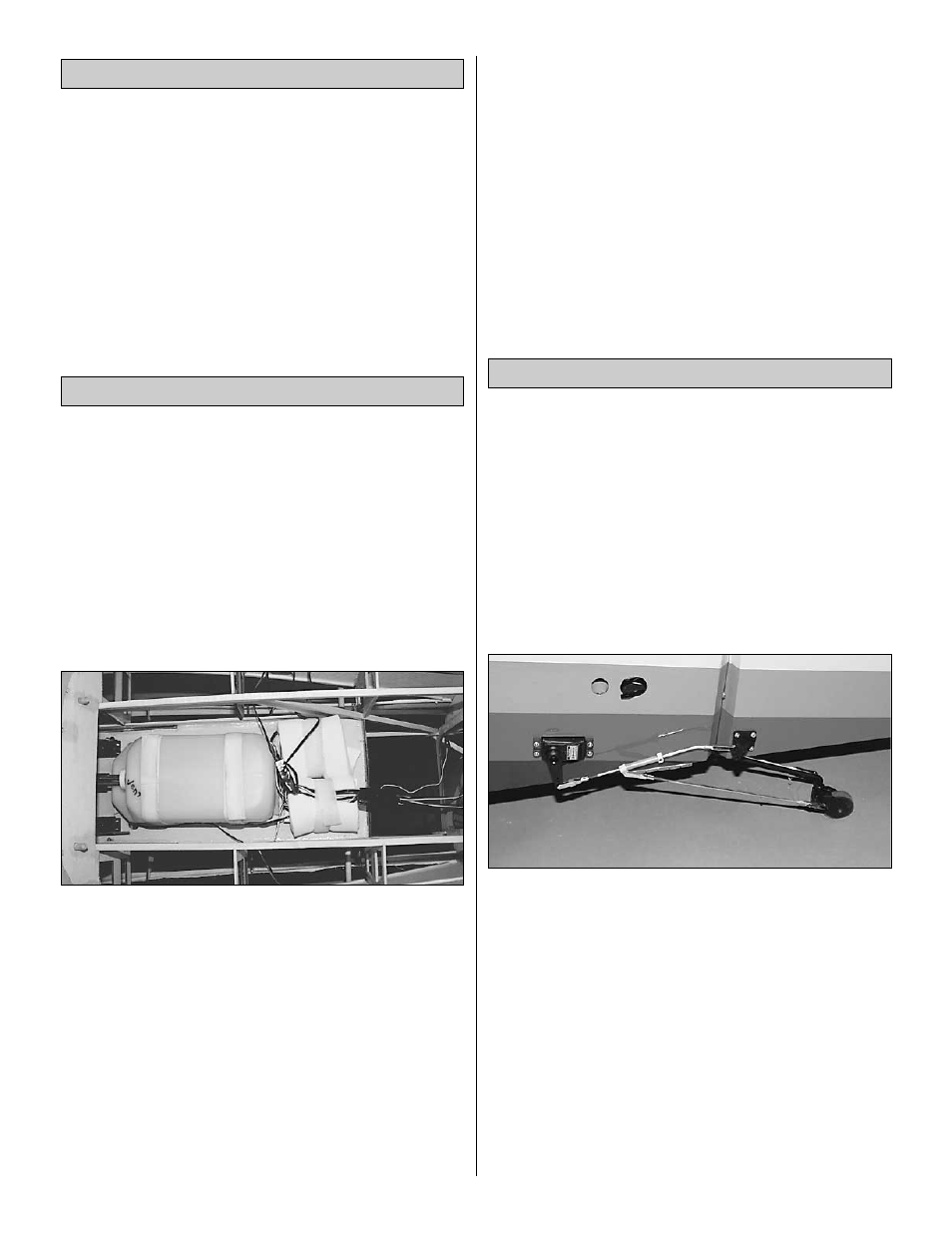

❏ 4. Assemble and install your tank, being sure to use the

appropriate type of tank, fuel fittings, etc for your fuel type.

(Note that the recommended Great Planes 24 oz. tank and

its included hardware are compatible with both gas and

glow fuels.) Glue a 2" long piece of leftover 1/4" x 1/4" balsa

at the leading and trailing edges of the tank. Secure the tank

to the tank/servo tray with Velcro

™

straps to allow easy

removal and service. NOTE: This location is ideal as it

mounts the tank over the CG and eliminates any CG

changes as fuel burns off. Most gasoline engines have

pumped carbs and will have no problem drawing fuel from

here. However, if your engine is not pumped or you are

unsure of its ability to draw this far, you will want to mount

your tank up against the firewall. You will need to build a tray

for it and secure it in that location.

❏ 5. Install any fuel filling equipment you choose to use. We

recommend mounting it into the fuse side just behind the

cowl. Note that it may be necessary to support the sheeting

with a piece of leftover ply.

❏ 6. Reinstall the engine to the mount and the muffler to the

engine. Connect the fuel lines to the carb and exhaust.

Follow your engine manufacturer’s recommendations for

installing any ignition or other equipment required for your

particular engine.

❏ 7. Reinstall the main gear, tail gear, wheels, wheel pants

and tail wheel. HINT: Even after the servo tray gets glued in

place you can still access the main gear nuts by reaching in

through the wing opening.

❏ 1. Reattach all control horns.

❏ 2. Mount all servos in the aircraft and fuselage servo tray,

being sure to secure all servo lead/extension joints with

heatshrink, tape or other protective covering to avoid an

accidental disconnect. Note that the servo lead/extension

connection at the wing/fuse joints and stab/fuse joints do

not get permanently secured in this manner. The servo tray

will not get glued in until all radio gear has been installed for

easy handling and set up. HINT: With removable flying

surfaces such as the Extra’s wings and stab, it is easiest to

do pushrod set up with the surfaces off the aircraft and the

receiver and receiver battery outside the aircraft.

❏ 3. Build your pushrods and hook up the servos to the

control surfaces, being sure to properly center the servos

and check direction on all controls. On the prototype we

used Dubro

®

giant scale control horns, steel clevises and

4-40 rod threaded on one end and soldered on the other for

all except the throttle and kill switches.

IMPORTANT NOTE: NEVER use threaded clevises on both

ends of any pushrod, as vibration may unscrew the pushrod

from both clevises!

NOTE: We strongly recommend using non-metal flexible

pushrods (GPMQ3710) and nylon clevises (GPMQ3800) for

all pushrods going to any gasoline engine or servo operated

kill switch as a precaution against “noise” traveling back to

the radio equipment and causing radio inconsistencies

or interference.

Final Servo & Receiver Installation

Install the Hardware

Paint the Model

44