Great Planes Giant Extra 330L Kit - GPMA0250 User Manual

Page 40

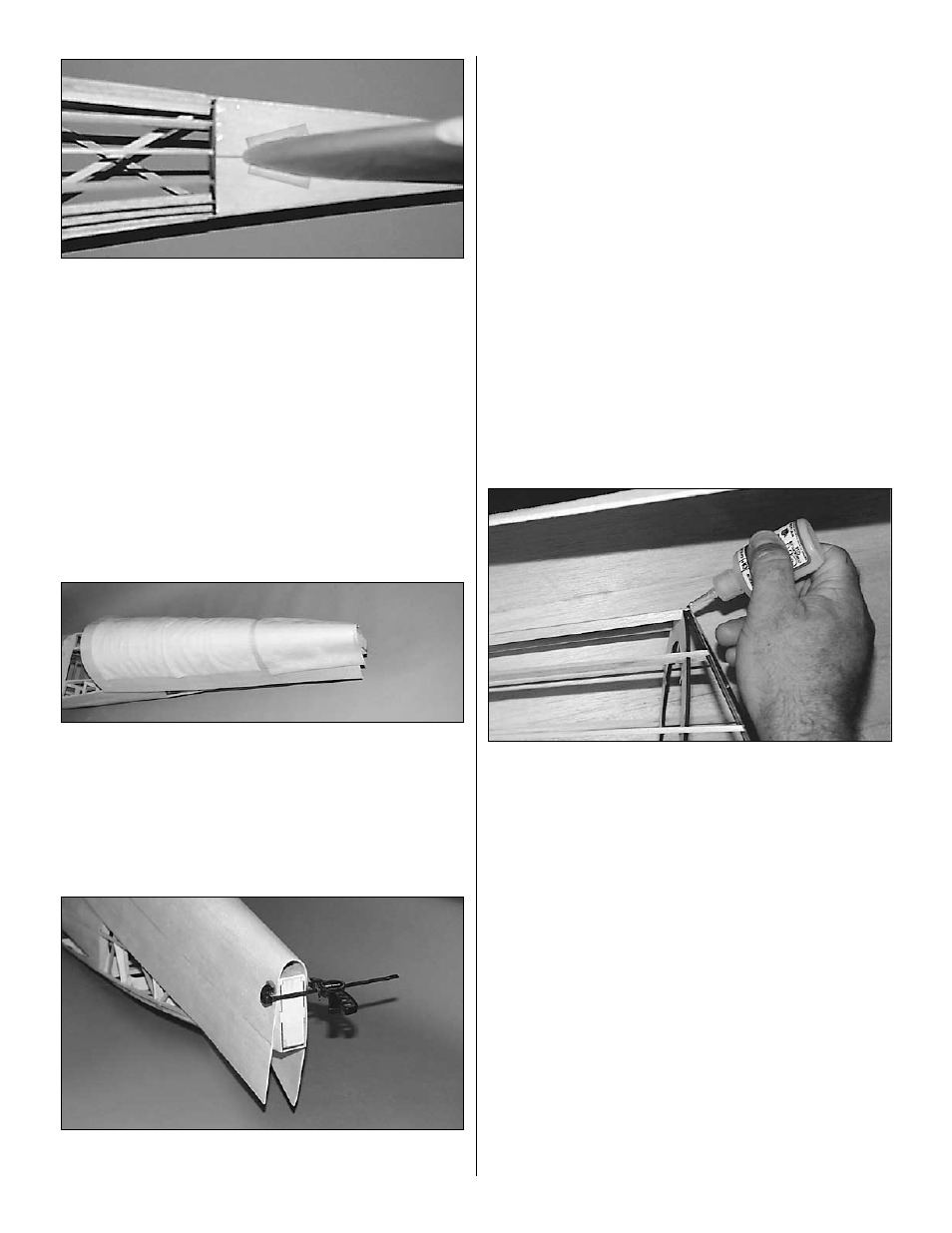

❏ 9. From leftover 1/4" x 1/4" balsa, cut two 2" long fin

locators. Glue the two locators as shown in the photo,

being careful not to glue the fin in place. Remove the fin

and set it aside. NOTE: These fin locators will be used to

properly position your fin later.

❏ 10. Select the five 3/32" x 4" x 36" long sheets, and

carefully inspect all 5 sheets. Select the softest sheet for the

center piece. Edge glue the 5 sheets, creating the turtle

deck sheeting. NOTE: The center sheet has to do a sharp

bend. It is important that you use the softest sheet to

minimize the chance of it splitting.

❏ 11. Wet one side of the sheet liberally. This will be the

outside of the turtle deck sheeting. Let the sheet set flat for

5 minutes to allow the water to soak into the sheeting.

❏ 12. Position the sheet over the turtle deck with the center

sheet centered on the top stringer and a small amount of

excess hanging behind the trailing edge of the fin plate (do not

end the sheeting at TD4). Lay very wet paper towels along the

center sheet and allow gravity to start to curve the sheet for

approximately an hour. Respray the entire sheet and the paper

towels and gradually pull the sheeting down. Repeat this

process until the sheeting hangs easily over the deck.

❏ 13.When the sheeting has curved enough, clamp the sides

to the fuse bottom on both sides and clamp the rear of the

sheeting across the rear of the fuse. Allow the sheeting to dry

completely overnight. NOTE: This is probably the most time

consuming step of the entire kit. Take your time and be

patient, being careful not to split the sheeting. If you are

patient and allow the water and gravity to work together, the

sheeting will bend smoothly and cleanly and you’ll get a great

looking turtle deck. If you try to rush it you will likely split the

sheet and have to start over again.

❏ 14. Double check that the sheeting is completely dry

before continuing. While the sheeting is still clamped in

place, lay the fuselage on its side. Using a straight edge,

trim the left side of the sheeting flush with the top of the

outer box longeron. Trim the right side of the sheeting 1/4"

below the outer box longeron.

❏ 15. Using medium CA, glue the turtle deck sheet to the

left side gluing stringer and longeron.

❏ 16. Confirm that the sheet is tight against the formers,

and trim the right side a little at a time until it mates to the

gluing stringer and longeron.

❏ 17. Roll the sheeting back, on and off the stringers a few

times until you can position it easily. Make sure it has good

contact with the stringers and formers along the whole

length of the turtle deck. When you are confident fitting it,

lay a bead of medium CA along all the turtle deck stringers,

formers, and the right side gluing stringer and longeron.

Position the sheeting in place and hold firmly along the

stringers and formers until the CA has fully cured. NOTE: It

is not as important that you get glue on every joint as it is

that the sheeting makes good contact with all the stringers

and formers along the whole length of the deck. This

sheeting is a critical structural component of your

aircraft and must be well fitted. In the next step you can

catch any places where you did not get a good coating of

CA, but only if you made good contact in this step.

❏ 18. Once the CA has dried, turn the fuselage upside

down and use thin CA to back up any places where the

sheet did not get adequately glued, but only if the sheet is

already making good contact. If it is not and you attempt to

force it now, you will likely split your sheeting and have to cut

it off and start over.

40