Great Planes Corsair 40 Kit - GPMA0177 User Manual

Page 34

We have found that it's much simpler to do all hinging and

control horn installation after the model is covered.

D 1. Cut the hinge slots in the stab and elevators using the

technique described in the Expert Tip section following

these four steps Test fit the elevators to the stab with the

joiner wire in position When satisfied with the fit, remove

the elevators Pack the joiner wire holes in the elevators

with 30-minute epoxy Then install the elevators on the stab

Make sure that both elevators are parallel with each other

Use a paper towel dampened with rubbing alcohol to

remove any excess epoxy that squeezes out.

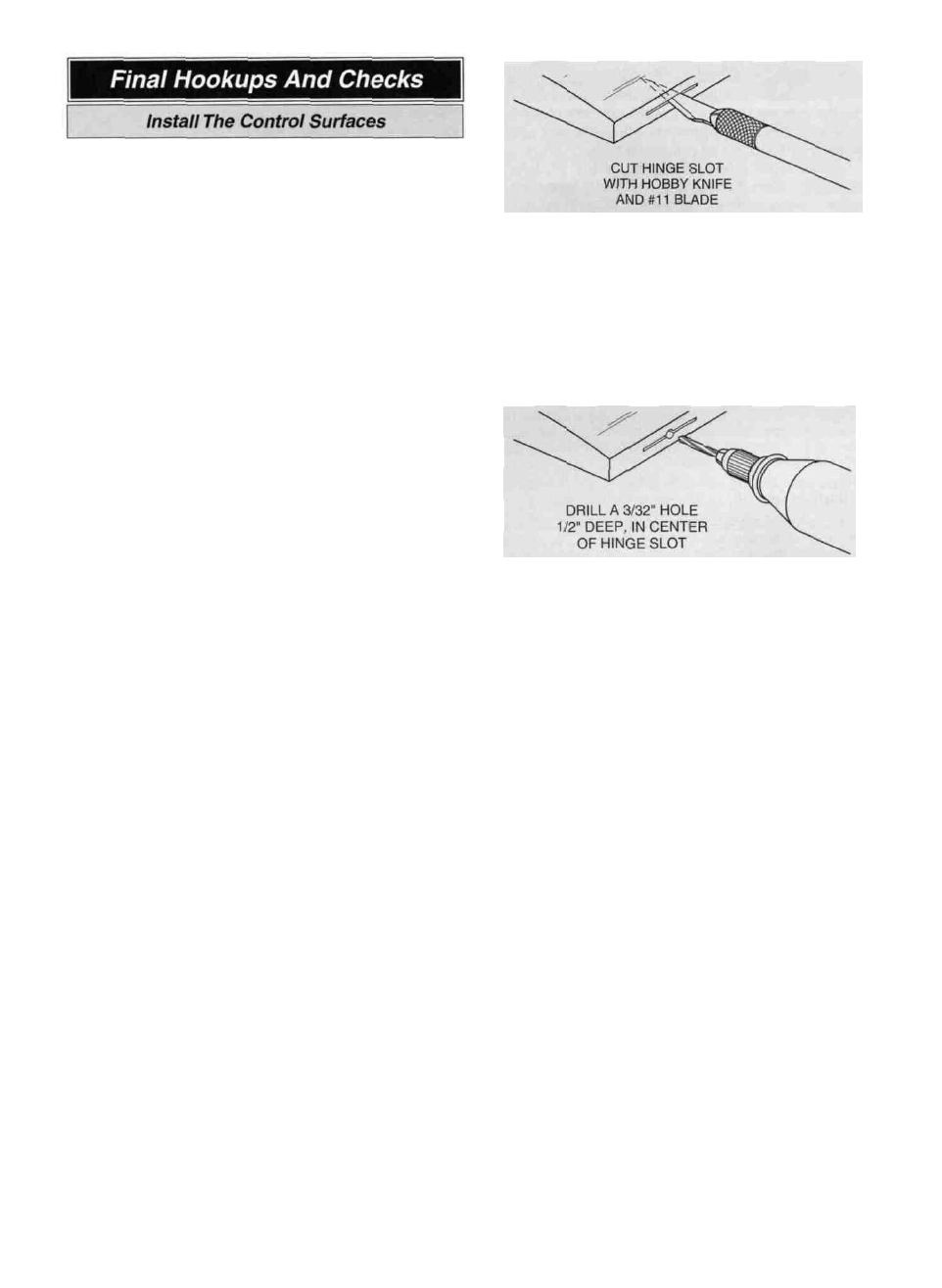

D 1. Cut the hinge slot using a #11 blade in a standard #1

knife handle The CA hinges provided have a thickness

that fits this type of slot very well Trial fit the hinge into

the slot. If the hinge does not slide in easily, work the

knife blade back and forth in the slot a few times to

provide more clearance (it is really the back edge of the

blade that does the work here in widening the slot).

D 2 Install the rudder following the same procedure used

to install the elevators

D 3. Install the ailerons on the wing, using four hinges

each.

D 4 After the epoxy has cured, CA the hinges in the control

surfaces.

Note: Refer to the fuse plan for the hinge making

instructions. Cut 16 hinges from the 2" x 9" supplied

material

D Drill a 3/32" hole, 1/2" deep, in the center of the

hinge slot. If you use a Dremel Moto-Tool for this task, it

will result in a cleaner hole than if you use a slower

speed power or hand drill Drilling the hole will twist some

of the wood fibers into the slot, making it difficult to insert

the hinge, so you should reinsert the knife blade, working

it back and forth a few times to clean out the slot.

C. Trial fit the hinges into the slots and temporarily attach

the control surface to verify the fit and operation

The hinge material supplied in this kit consists of

a 3-layer lamination of mylar and polyester It is specially

made for the purpose of hinging model airplane control

surfaces Properly installed, this type of hinge provides

the best combination of strength, durability and ease of

installation We trust even our best show models to these

hinges, but it is essential to install them correctly.

Please read the following instructions and follow them

carefully to obtain the best results These instructions

may be used to effectively install any of the various

brands of CA hinges.

The most common mistake made by modelers when

installing this type of hinge is not applying a sufficient

amount of glue to fully secure the hinge over its entire

surface area, or, the hinge slots are very tight, restricting

the flow of CA to the back of the hinges This results in

hinges that are only "tack glued" approximately 1/8" to

1/4" into the hinge slots The following technique has

been developed to help ensure thorough and

secure gluing.

D Rather than just making a single slit, it is better to cut

away a narrow rectangle of covering to provide an

adequate opening for the CA glue to wick into the slot.

E Insert the hinges and install the control surface Verify

the left-right positioning of the control surface, and close

up the hinge gap to 1/32" or less It is best to leave a very

slight hinge gap, rather than closing it up tight, to help

prevent the CA from wicking along the hinge line Make

sure the control surface will deflect to the recommended

throws without binding If you have cut your hinge slots

too deep, the hinges may slide in too far, leaving only a

small portion of the hinge in the control surface To avoid

this, you may insert a small pin through the center of

each hinge, before installing This pin will keep the hinge

centered while installing the control surface Remove the

pins before proceeding

34