Great Planes Corsair 40 Kit - GPMA0177 User Manual

Page 25

D 7. Cut off approximately 1/2" of threads on the 4"

threaded rod (WIRES72). Completely screw the threaded

rod into one end of the 12" inner pushrod tube

(PLTB012). Attach a solder clevis to the throttle arm and

insert the inner pushrod tube into the outer pushrod tube in

the firewall. With 3/4" of inner pushrod tube protruding from

the outer pushrod tube, bend the threaded rod to clear the

muffler. Rotate the throttle arm toward the firewall and mark

the location where the threaded rod passes through the

solder clevis. Cut the threaded rod at the mark and solder

the clevis onto it.

We strongly recommend that the engine be removed from

the engine mount and stored back in its box to prevent dust

from entering the engine.

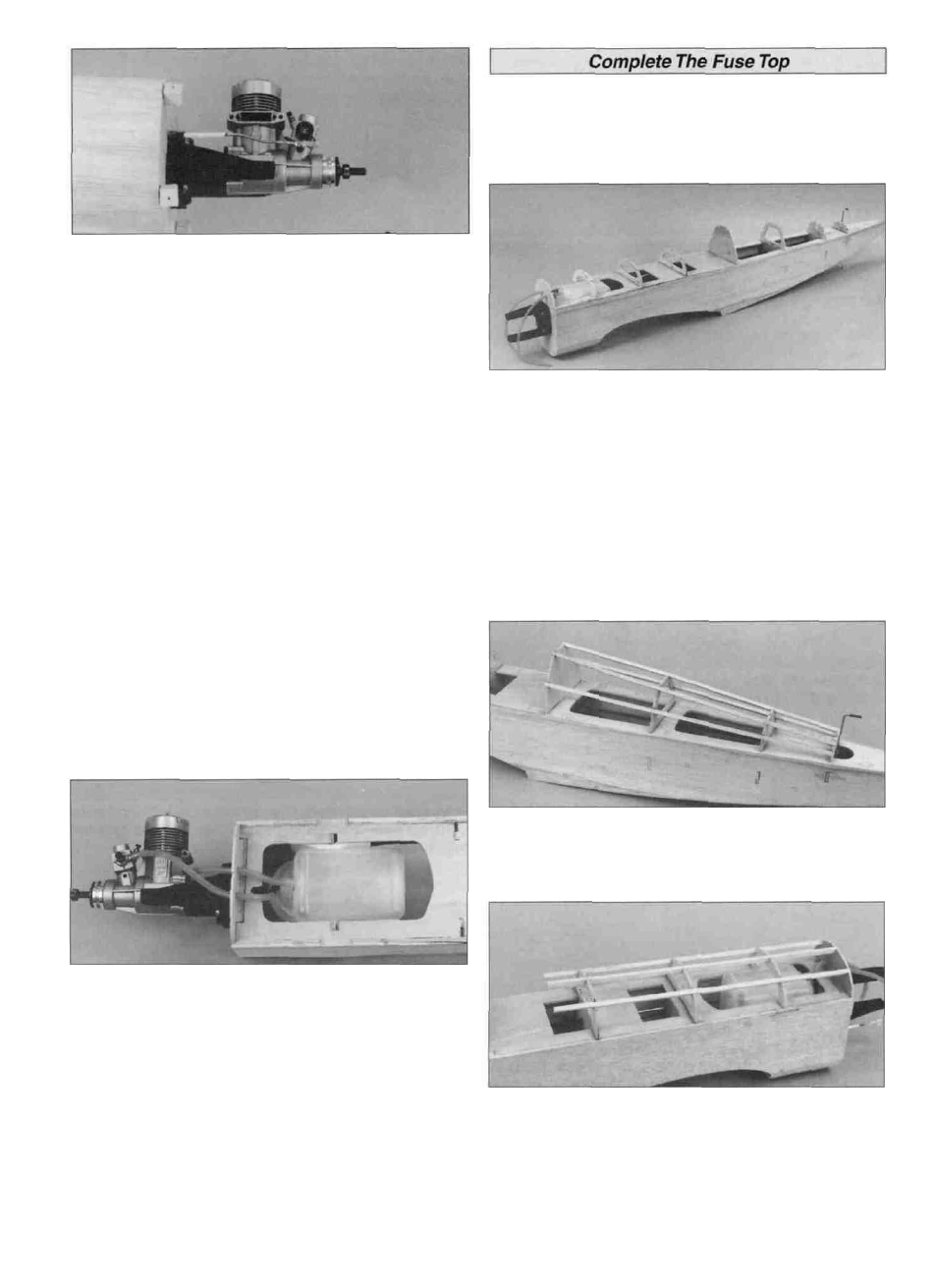

D 1. Glue the die-cut ply formers F-2B, F-3B, F-4B, F-6B,

F-7B, F-8B and F-9B (F02, F03 and F04) into their notches

on the fuse top. Use a triangle to maintain the vertical

alignment of the formers.

D 2. From a piece of 1/8" scrap ply, cut two 1/2" x 3-1/2"

servo tray doublers. Glue the doublers on the forward and

aft edges of the servo cutout in the forward crutch.

Note: We used a 10 oz. Great Planes Tank (#GPMQ4104)

in out prototypes. By using the supplied right angle fuel

supply tube, the fuel tubing can be routed to the top of the

firewall without the risk of kinking the tube. You may also

route the fuel tube below the forward crutch to make fishing

the tubes a little easier. The choice is yours.

D 8. Temporarily install the fuel tank. It's much easier to see

what is happening at this stage of construction. Decide

where you want the fuel and vent tubes to exit the firewall

and mark the locations. Remove the tank and drill two

15/64" (or 7/32") fuel tube exit holes through the firewall at

the locations you marked. Before reinstalling the fuel tank,

fuelproof the fuel tank compartment. Wrap the fuel tank in

foam to prevent fuel foaming from vibration. Reinstall the

tank and connect the fuel tubes. Check for kinks and rectify

any problems before proceeding.

D 3. Cut two of the 3/16" x 3/16" x 30" balsa stringers in

half. Fit the stringers from former F-6B to F-9B and glue

them in place with thin CA. Sand the end of the stringers

flush with F-6B and F-9B.

D 4. Cut three 13" long pieces f r o m the remaining

3/16" x 3/16" balsa. Install the stringers flush with the front

of the firewall, allowing them to overhang former F-4B.

25