Great Planes Corsair 40 Kit - GPMA0177 User Manual

Page 17

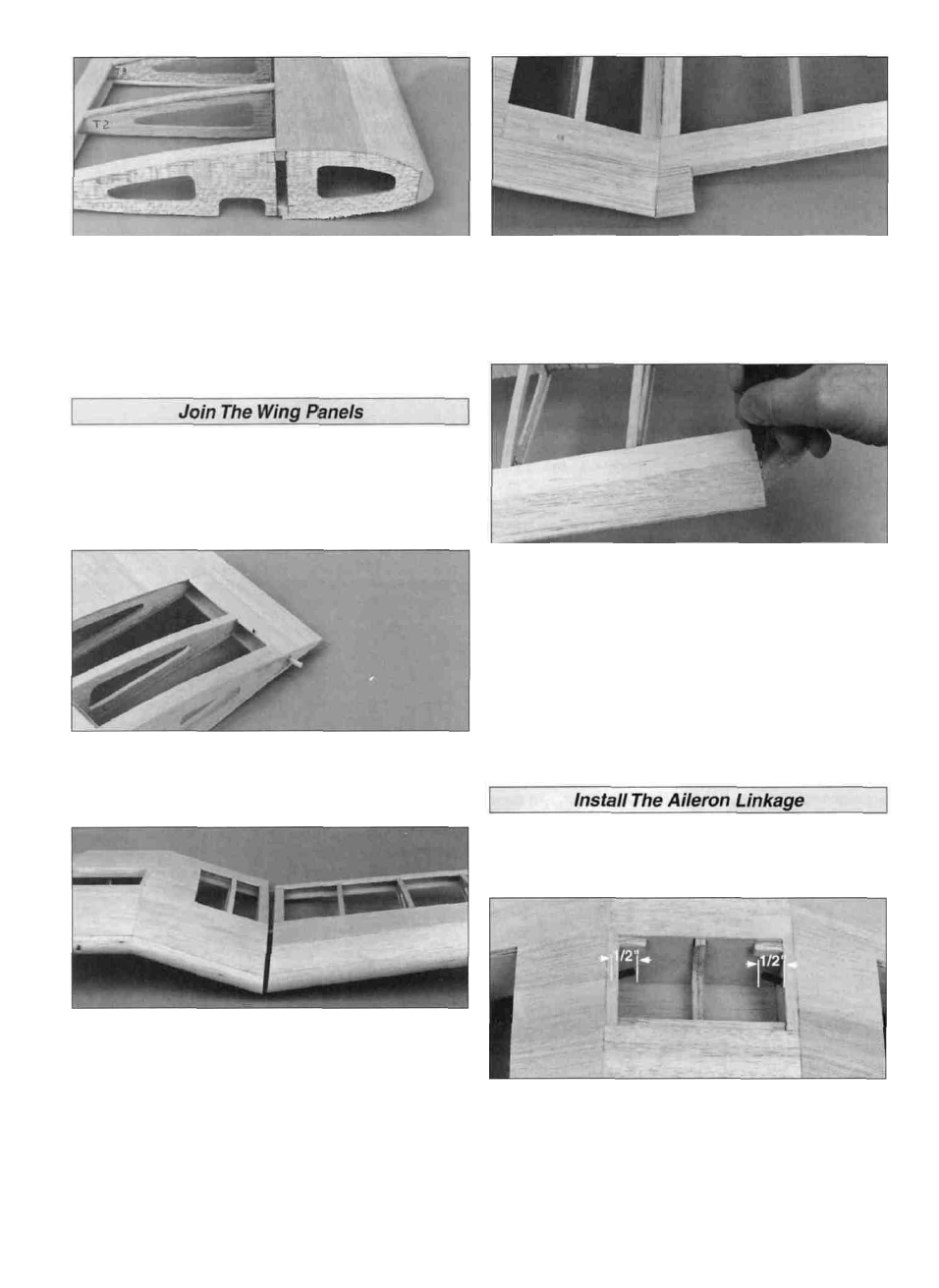

D D 9. Cut the access slot between the spars in T-1 for the

wing center spar.

D 3. Sand one end of the remaining 1-1/8" x 1" tapered TE

to match the angle of the wing center section. Use medium

CA to glue both 1" TE'S in position.

That's one wing panel down. Now, go back and build the

other one. Remember to build a right and left outer

wing panel.

NOTE: Before actually using any glue, test fit the entire

assembly together to make sure the wing panels fit

properly.

D 4. While holding an aileron against the inside edge of the

wing panel sub TE, draw a line on it that matches the inside

edge of the wing tip TE. Cut the aileron 1/8" shorter than

the TE opening to allow for covering material.

D 5. Draw a centerline on the forward edge of the aileron.

Sand the forward edge of the aileron to a "V". Refer to the

cross section of the wing on the plans for the desired angle.

D 1. Cut the 1/8" x 2" hardwood alignment dowel

(DOWEL049) in half. Insert 1/2" of the 1/8" x 1" alignment

dowel through the hole at the aft end of R-5. Glue it to the

inside of the TE perpendicular to R-5.

D 2. Assemble only one wing panel to the center section at

a time. Completely coat the spars and shear webs inside

the access slot with 30-minute epoxy. Use a stick or brush

to apply epoxy to rib T-1. Slide the wing panel on the wing

center spar. Glue the 1/8" alignment dowel to the inside TE

of the wing panel. Make sure the panel and center section

are aligned from the LE to TE, then clamp or tape them

together until the epoxy cures.

D 1. Cut two 5" long pieces from one of the 24" outer

pushrod tubes (PLTB011). Sand the outside of the tubes

with 80-grit sandpaper to roughen them for better glue

adhesion.

D 2. Slide the pushrod tubes through the holes in ribs R-2

through R-4. About 1/2" of the tubes should protrude into

the aileron servo bay. Glue the pushrod tubes to the ribs

with medium CA.

17