FloAire Pyroscat Enclosure User Manual

Page 7

www.morganthermalceramics.com

Page 6

P029_02:2014

Fire Rated Enclosure

Installation Technique and Design

Advisory Manual

approved firestop sealant and thickness (typically 1/4” (6mm))

shall be as specified in an approved UL / ULC firestop design

listing. When there is not sufficient annular space around the

duct to run the Pyroscat Duct Wrap XL enclosure system

continuous through the fire rated assembly, the enclosure may

terminate above and below the floor/ceiling assembly or on

either side of a wall assembly as shown in Figure 2. When this

method is used, the Pyroscat Duct Wrap XL must be

mechanically attached on either side of the fire rated assembly

using one of the attachment methods described in Section D,

spaced a maximum of 1-1/2” (38mm) from the fire rated

assembly.

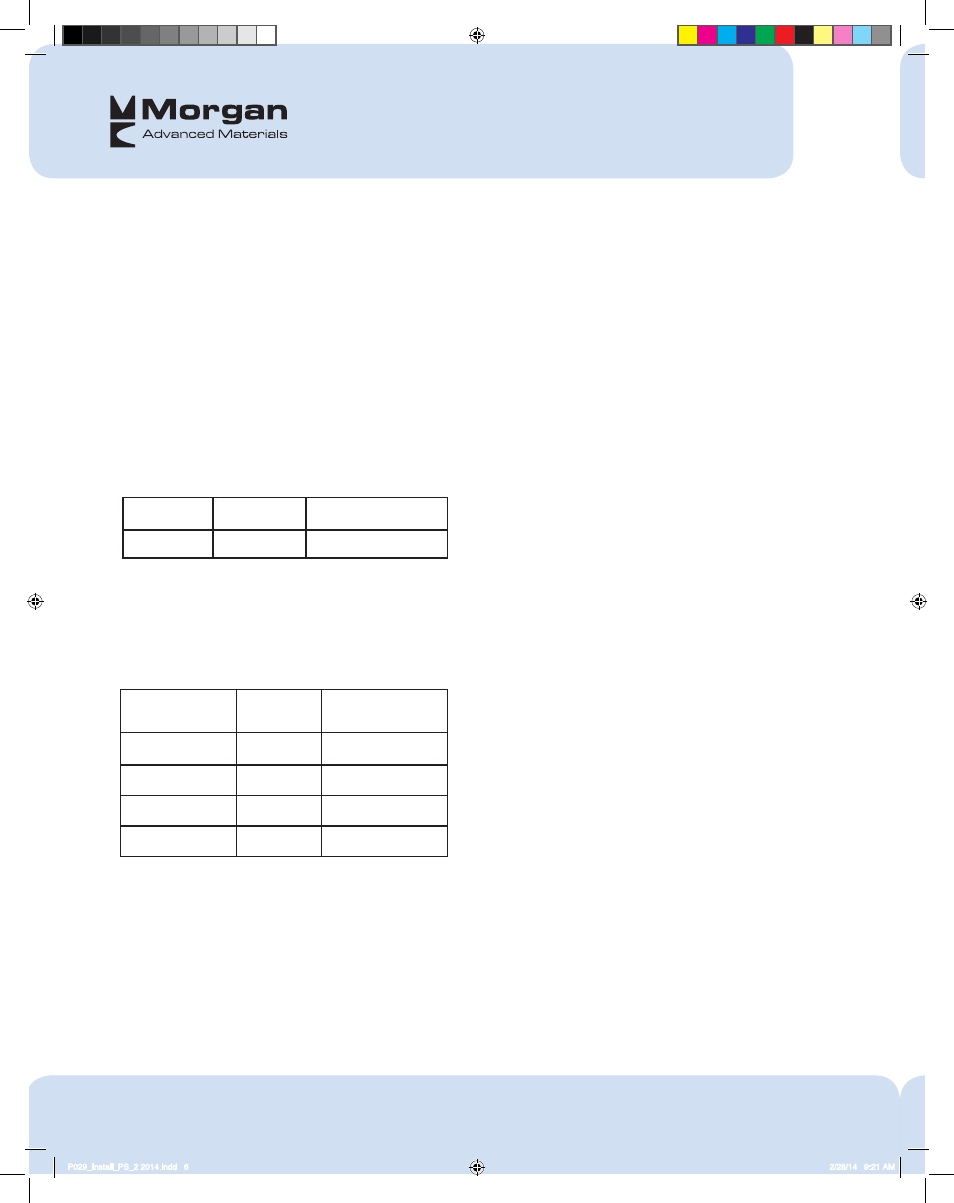

G. Support Hanger Systems

1) Grease ducts: Trapeze support hangers shall be spaced on

maximum 60 in. (1500 mm) centers. Hanger rods or straps

shall be anchored with steel drop in or wedge expansion type

masonry anchors. No additional protection is required for

hangers and supports meeting the requirements of the Table

below.

2) HVAC ducts: Trapeze support hangers shall be spaced on

maximum 60 in. (1500 mm) centers. Hanger rods or straps

shall be anchored with steel drop in or wedge expansion type

masonry anchors. No additional protection is required for

hangers and supports meeting the requirements of the Table

below.

9. Maintenance and Repair

No maintenance is required when installed in accordance with

Thermal Ceramics (TC) installation instructions. If damage is

limited to the foil facing, aluminum foil tape can be used to repair

the foil facing. If an area of blanket is found to be damaged the

following procedure must be incorporated. If the damaged area is

larger than 8” (203mm) x 8” (203mm) the entire wrap section must

be removed and replaced according to TC installation

instructions. If the damaged area is small (less than 8” (203mm)

x 8” (203mm)), the damaged area must be cut away and replaced

with a new section 1” (25mm) larger in length and width than the

cut out, such that the new section can be compressed tightly into

the cut out area. All cut edges of the new section must be taped

and sealed with aluminum foil tape. The new section must be

held in place with either pinning or banding per TC installation

instructions.

10. Limitations

Thermal Ceramics Pyroscat Duct Wrap XL shall be installed in

accordance with these installation instructions and

appropriate laboratory design listings. The integrity of

Pyroscat Duct Wrap XL systems is limited to the quality of the

installation.

* For personal protective equipment recommendations, please see SDS.

Thermal Ceramics and Pyroscat are trademarks of Morgan Advanced Materials. Pyroscat products

are manufactured by Thermal Ceramics and are distributed by authorized distributors.

.

Hanger Cross

Section

Maximum

Perimeter, in (mm)

Trapeze Support (or

equivalent Yield Strength),

in (mm)

3⁄8 in (10 mm)

threaded rod

148 (3759)

2 (51) x 2 (51) x 1⁄8 (3) in

angle

Hanger Cross Section

Max. Perimeter,

in (mm)

Trapeze Support (or

equivalent Yield Strength),

in (mm)

1 in x 16 gage strap

(25 mm x 1.5 gage

strap)

100 (2540)

1⁄4 in (6 mm) threaded

rod

50 (1270)

1

1

⁄

2

(38) x 1

1

⁄

2

(38) x 3⁄16

(5) angle

3⁄8 in (10 mm) threaded

rod

150 (3810)

1

1

⁄

2

(38) x 1

1

⁄

2

(38) x 3⁄16

(5) angle

1⁄2 in (12.7 mm)

threaded rod

218 (5540)

2 (51) x 2 (51) x 1⁄4 (6)

angle

P029_Install_PS_2 2014.indd 6

2/28/14 9:21 AM