FloAire Pyroscat Enclosure User Manual

Page 5

www.morganthermalceramics.com

Page 4

P029_02:2014

Fire Rated Enclosure

Installation Technique and Design

Advisory Manual

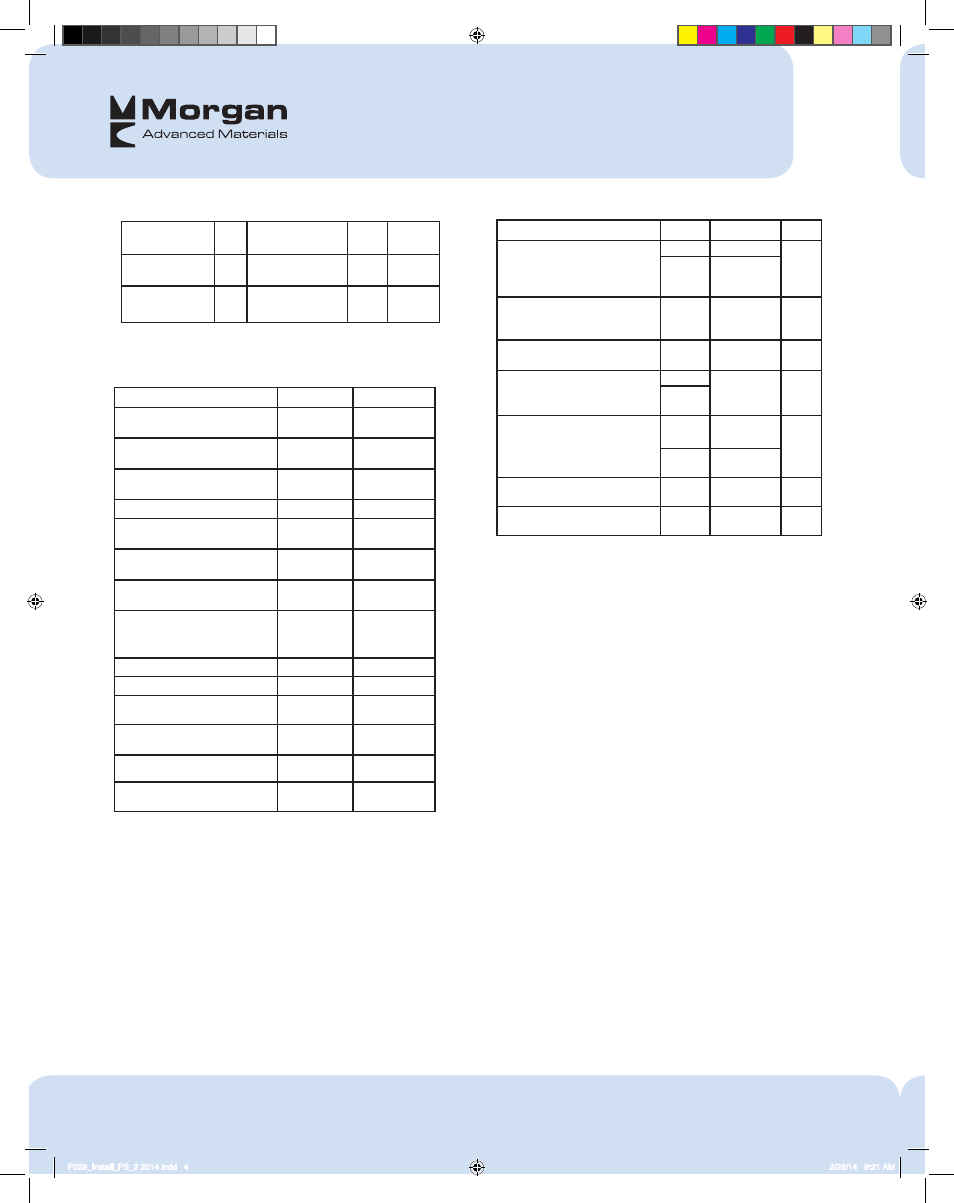

4. Physical Characteristics

5. Performance Specifications

6. Listings/Building Code Reports

7. Storage

Thermal Ceramics Pyroscat Duct Wrap XL must be stored in a

dry warehouse environment on pallets. Pallets should not be

stacked.

8. Installation

Thermal Ceramics Pyroscat Duct Wrap XL shall be installed

by a qualified contractor in accordance with manufacturer’s

instructions and laboratory design listings.

Materials and Equipment

• Thermal Ceramics Pyroscat Duct Wrap XL blanket

• Aluminum foil tape

• Glass filament reinforced tape (optional)

• Carbon steel or stainless steel banding material,

minimum 1/2” (13mm) wide, minimum 0.015” (0.4mm) thick,

with steel banding clips

• Hand banding tensioner and crimping tool

• Minimum 12 gage (3mm) steel insulation pins; steel speed

clips, minimum 1-1/2” (38mm) square or

1-1/2” (38mm) diameter, or equivalent sized cup-head pins;

• Capacitor discharge stud gun

• Thermal Ceramics FastDoor™ XL

• An approved firestop sealant

Product

Unit Size

Units/

Ctn.

Wt./

Ctn.

Pyroscat Duct

Wrap XL

Roll

1-1/2” x 24” x 25’

1

37.5 lbs.

Pyroscat Duct

Wrap XL

Roll

1-1/2” x 48” x 25’

1

75 lbs.

Reference Standard

Standard No. Performance

Grease Duct Enclosure

System

ASTM E2336 Pass

Section 16.1 -

Non-Combustibility

ASTM E136

Pass

Section 16.2-Fire Resistance

(wall)

ASTM E119

Pass

Section 16.3 - Durability Test

ASTM C518

Pass

Section 16.4 - Internal Fire

Test

ASTM E2336 Pass

Section 16.5 - Fire Engulfment

(duct)

ASTM E814/

E119

Pass

ULC Grease Duct Test

Protocol

Pass

Standard Methods of Fire

Resistance Tests - Grease

Duct Assemblies

CAN/ULC

S144

Pass

Grease Duct Clearances

UL 1978

Pass

Air Ventilation Duct Enclosure ISO 6944

Pass

Surface Burning

Characteristics

ASTM E84

<25/50

Thermal Resistance

(R-value @ 75°F)

ASTM C518

7.3 per layer

Mold Growth

ASTM C1338 ULE Validated

Low VOCs

CA Standard

01350

ULE Validated

Listed Uses

Agency Listing

Layers

Grease Duct Enclosure per

ASTM E2336 and AC101 (2006,

2009, 2012 IMC, NFPA 96,

UMC, CMC)

UL

G18

2

ICC-ES ESR 2213

ULC Grease Duct Test Protocol

and CAN/ULC S144*

ULC

FRD 4, 7*

2

Grease Duct Insulation

(2003 IMC)

OPL

TC/BI 120-01 1

Through Penetration FireStop

System per ASTM E814,

UL 1479

UL

See Figure 2 1 or 2

ULC

1- or 2-hour Ventilation Duct

Enclosure per ISO 6944-1985

UL

HNLJ.V1,

19, 29

1

ULC

FRD 3, 5,

6, 18

3-hour Ventilation Duct

Enclosure per ISO 6944-1985

UL

HNLJ.V2

2

Electrical Circuit Protective

System

UL

FHIT.5

2

P029_Install_PS_2 2014.indd 4

2/28/14 9:21 AM