FloAire Pyroscat Enclosure User Manual

Page 14

www.morganthermalceramics.com

Page 13

P029_02:2014

Fire Rated Enclosure

Installation Technique and Design

Advisory Manual

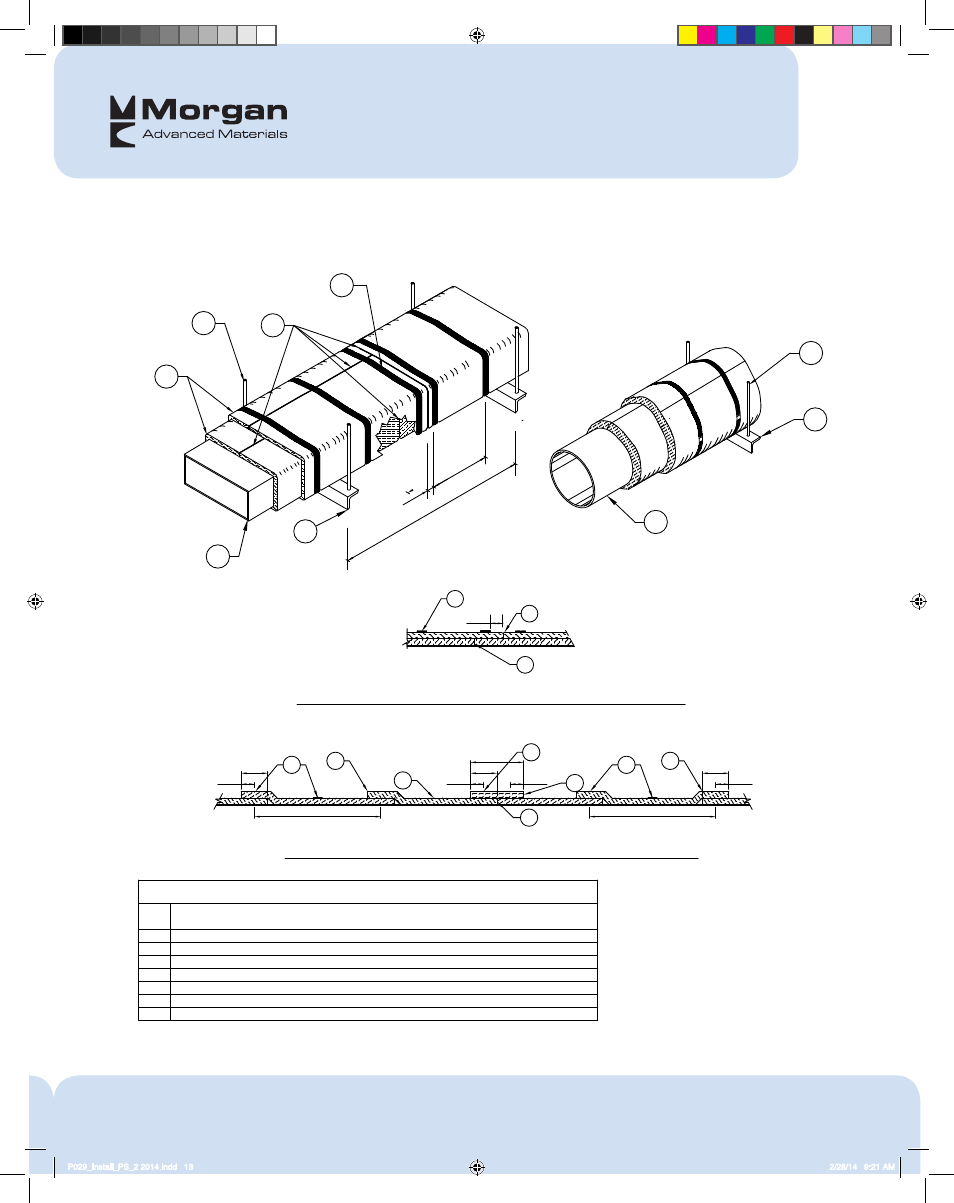

Grease and HVAC Duct Enclosure System

1 or 2 Hour Shaft Alternative / Zero Clearance to Combustibles

XL001-10

The integrity of Thermal Ceramics duct systems is limited to the quality of the installation.

Tight butt joints (no overlap) at perimeter and longitudinal joints, both layers for grease ducts

Min. 3" (75) overlap on perimeter and between adjacent blankets

Two Layers of XL Insulation for ASTM E2336 and CAN/ULC S144 Grease Duct Enclosures

LEGEND

1

4

5

3

2

Steel banding minimum 1/2" (13) wide by 0.015" (0.4) thick.

Optional 6" XL collar

6" (155)

Checkerboard Wrap Option

Telescope Wrap Option

21" (533) TYP.

Butt Joint Option

21" (533) TYP.

1 1/2" (38)

3" (75)

1 1/2" (38)

3" (75)

1 1/2" (38)

3" (75)

1 1/2" (38)

SINGLE LAYER INSTALLATION OPTIONS (2-Hour rated HVAC Duct per UL HNLJ V-19)

One Layer of XL Insulation for 2-Hour Air Ventilation Duct Enclosures

2

4

2

1

4

2

3

2

5

3

3

TWO LAYER INSTALLATION (Grease Duct per ASTM E2336 and CAN/ULC S144)

Butt Joint / Butt Joint Typical

Hangers - size dependent weight of assembly (see datasheet Section G)

Trapeze Supports - size dependent on weight of assembly (see datasheet Section G)

6

7

Steel Rectangular or Round Duct (size, gage and construction dependent per Listed Design)

8

1 1/2" (38)

6

7

8

1

2

3

7

60" (1500)

TYP.

8

1 1/2" (38)

10 1/2" (267 )O.C.

6

P029_Install_PS_2 2014.indd 13

2/28/14 9:21 AM