Part names and functions, Connection and wiring, Laser safety precautions – KEYENCE BL-600 Series User Manual

Page 2: Part names and functions connection and wiring

2

LASER SAFETY PRECAUTIONS

Follow the safety precautions below to ensure operator safety:

• Operate the BL-600 Series only according to the procedures

described in this instruction manual.

Otherwise, injury may occur due to exposure to the laser beam.

• Do not disassemble the sensor head.

Laser emission from the BL-600 series is not automatically stopped if

the sensor head is disassembled. If you disassemble the sensor head

for inspection or repair, you may be exposed to the laser beam.

If the BL-600 series malfunctions, contact KEYENCE immediately.

• Do not stare into the direct or specularly reflected beam.

Staring into the beam may result in serious eye injury.

• Protective enclosure

We recommend that you install a protective enclosure around the

sensor head to prevent any person from getting near the sensor head

during operation.

• Protective goggles

We recommend that you wear protective goggles when using the

BL-600 series.

• Stop laser emissions before cleaning the laser emission port.

Failure to stop the laser emission may expose eyes or skin to the laser

beam.

• Check the laser beam path.

To prevent exposure to the laser beam due to specular or diffuse

reflection, install a screen which offers the appropriate reflectance and

temperature characteristics to interrupt the reflected laser beam.

Do not install the BL-600 series in such a way that the laser beam

passes at eye height.

5. Safety Features Provided with the BL-600 Series

The BL-600 series is provided with the following safety features. Make

sure these features function correctly before operating.

• Laser emission caution LED (LASER ON LED)

During laser emission, the LASER ON LED illuminates. The LED ON

status can be checked through the laser protective glasses.

• Laser forced OFF command

Sending the laser forced OFF command to the BL-600 can inhibit

emission of laser beams. When working near the laser transmitter, be

sure to use the laser forced OFF command to avoid looking into the

laser beams.

When this command is selected, the bottom STABILITY LED flashes.

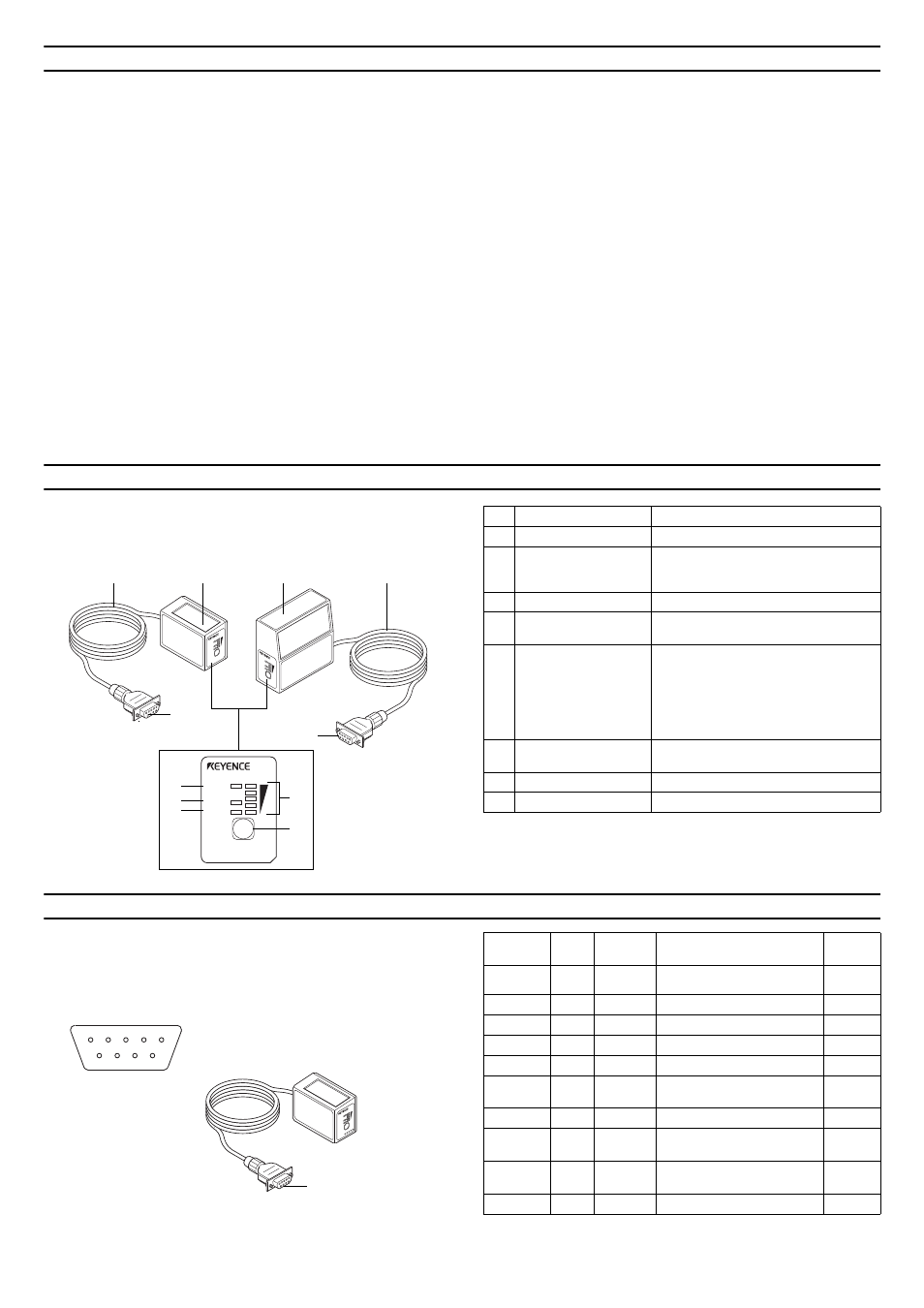

PART NAMES AND FUNCTIONS

CONNECTION AND WIRING

Pin assignment of the BL-600 Series power supply

connector

LAS

ER

ON

OK/NG

TIMING TES

T

BL

-60

0

LASE

R ON

OK/N

G

TIM

ING

TE

ST

BL-600

z

BL-600/601/600HA/601HA

z

BL-650HA/651HA

8

6

7

6

8

LASER ON

OK/NG

TIMING

TEST

BL-600

1

2

3

4

5

7

No.

Name

Function

1

LASER ON LED

Lit when laser beams are emitted.

2

OK/NG LED

• When OK output is ON: The green LED

lights.

• When NG output is ON: The red LED lights.

3

TIMING LED

Lit when trigger input is ON.

4

STABILITY LED

Displays the reading stability and the BL-600

operating status.

5

TEST SWITCH

This switch allows the following operations:

• Start the test mode.

• Pressing the switch once within two

minutes reads the bar code once.

• Sets the communication protocol to the

intival values when sending the settings.

• Reset the error status.

6

Transmitter/receiver

Window to emit laser beams and receive

reflected lights.

7

Power supply connector

Connected to the special power supply unit.

8

Cable

Cable length is 1.8 m.

LAS

ER

ON

OK/N

G

TIMING TES

T

4

5

3 2 1

9 8 7 6

Connector pin assignment

D-sub 9-pin (female)

#4-40 screw (male)

Power supply

Connector

Pin No.

Cable

color

Symbol

Description

Signal

direction

Connector

case

Shield

FG

Frame ground

---

1

Yellow

TIM

Trigger input

Input

2

Brown

RD (RXD)

Receives RS-232C data

Input

3

Purple

SD (TXD)

Sends RS-232C data

Output

4

White

OK

OK output

Output

5

Black

GND (SG)

Ground (Common ground for

respective signals)

---

6

Gray

NG

NG output

Output

7

Pink

RS (RTS)

Request to send RS-232C data

(always ON)

Output

8

Blue

CS (CTS)

Enable to send data through

RS232C

Input

9

Red

+5 V

+5 V DC power supply

Input