Controller unit (i/o terminal section), 1 before installation, About static elimination performance – KEYENCE SJ-M400 User Manual

Page 4: Installation precautions, Before installation

4

1-3

Names and Functions of Parts

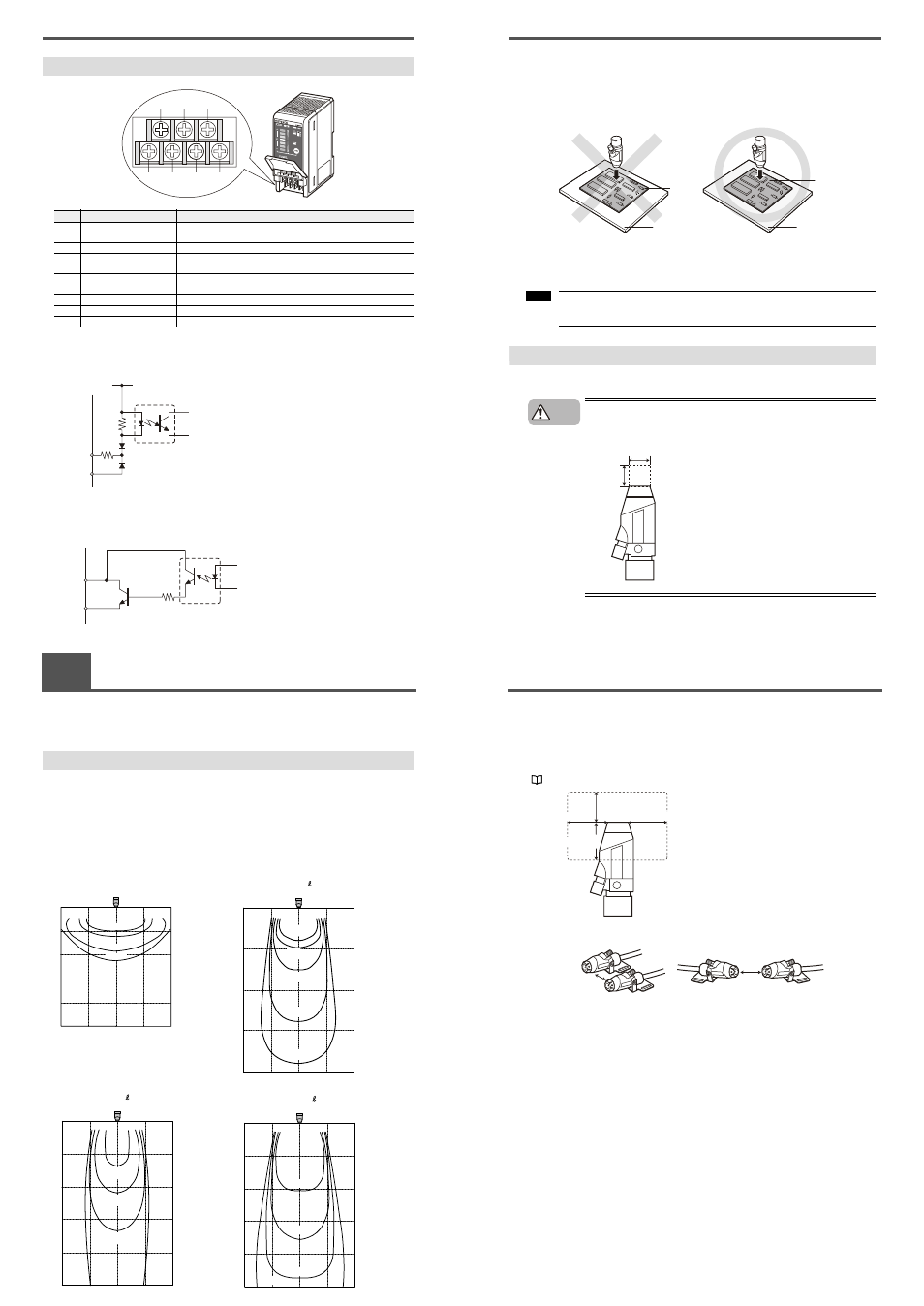

Controller Unit (I/O terminal section)

■ Input circuit diagram

■ Output circuit diagram

Number

Name

Function

(1)

Condition/ion level alarm

output terminal

Outputs when static elimination performance is influenced by an

unstable operating environment or when the ion emission level drops.

(2)

Valve output terminal

Outputs the ON/OFF signal for the valve.

(3)

Trigger input terminal

Static elimination can be turned ON/OFF by shorting this terminal with

(6).

(4)

Ground terminal

Be sure to connect a Class D ground (maximum resistance of 100

Ohms).

(5)

DC power terminal

24 VDC ±10%

(6)

0V terminal

0V for power and 0V for I/O

(7)

Alarm output terminal

Outputs when an alarm occurs. (N.C.)

(1)

(4)

(5)

(6)

(7)

(2)

(3)

+24V

3k

Ω

INPUT (3)

0V (6)

Input a no-voltage contact (relay, etc.)

or NPN open collector to INPUT and 0V.

[ (3) (trigger input)]

OUT

DC40V

100mA

0V (6)

Open collector output

[ (2) (valve output), (1) (condition/ion level alarm output), (7) (alarm output)]

2-1

Before Installation

This section describes the static elimination performance of the SJ-M400 Series.

Before you install the SJ-M400 Series, fully calculate the distance between the Static Elimination Head

up to the target object and the time required for static elimination.

About Static Elimination Performance

The following shows a typical example where static is eliminated from an aluminum plate (20 pF) 150 x

150 mm square charged to +1000 V by the SJ-M400 Series.

■ Static elimination area

The following graphs show the relationship between the time required for eliminating static from a target

object charged between +1000 to +100 V and the distance from the charged object up to the Static

Elimination Head.

No air

50

100

150

100

50 100 150

1.0 sec

200 mm

200 mm

200

300

400

500 mm

0.5 sec

5.0 sec

10 sec

23 Hz Air flow rate 20 N /min (pressure 0.06 MPa)

50

100

150

50 100 150 200 mm

200 mm

200

400

600

800 mm

0.5 sec

5.0 sec

2.0 sec

10 sec

1.0 sec

23 Hz Air flow rate 60 N /min (pressure 0.18 MPa)

50

100

150

50 100 150 200 mm

200 mm

200

400

600

800

1000 mm

0.5 sec

2.0 sec

1.0 sec

5.0 sec

23 Hz Air flow rate 230 N /min (pressure 0.7 MPa)

50

100

150

50 100 150 200 mm

200 mm

200

400

600

800

1000 mm

0.5 sec

2.0 sec

1.0 sec

5.0 sec

2-1

Before Installation

■ Appropriate static elimination method

Pay attention to the following points to ensure that static elimination is performed appropriately.

Static elimination cannot be performed accurately at locations where the target object is

touching a metallic body (grounded body).

Eliminate static from the target object at locations where it is not directly touching metallic bodied

(grounded body).

Static will be eliminated from only the surface of the insulated body (board, etc.) that is facing

the Static Elimination Head.

When eliminating static from both sides of a target object, install two SJ-M Series as one SJ-M Series

must be installed on either side of the target object.

Install the Static Elimination Head so that it can be easily accessed, for example, for

replacement of parts and cleaning.

Installation Precautions

■ Installation site

Install the tip of the SJ-M040 paying attention to the following point.

●

Install the Static Elimination Head away from the wall or surrounding

objects.

Insulating mat

Metal

Board

Board

Note

CAUTION

20 mm or more

10 mm

or more

2-1

Before Installation

■ Interference

The Static Elimination Head may not function properly if there is a conductor (grounded body) located

nearby or if two or more units are used close to each other. In such an installation, refer to the figure

below and maintain the indicated distance between the conductor (grounded body). If a conductor

(grounded body) is located inside the distances indicated below, adjust using the ion balance manual

setup.

"3. Adjusting ion balance" (page 7)

When two SJ-M Series units are used, refer to the figures below, and install the units so that the

following distances are maintained between the two Static Elimination Heads.

70 mm or more

100 mm or more

100 mm or more

100 mm or more

150 mm or more

150 mm or more