3 performing maintenance on the air filter, Performing maintenance on the air filter, 1 timing charts – KEYENCE SJ-F300 Series User Manual

Page 11: Timing charts, 5specifications

10

4-2

Performing Maintenance on the Electrode Needles

3

Install the Electrode Unit.

Make sure that the lock switch on the

Static Elimination Blower Unit is unlocked,

and then insert the Electrode Unit.

Make sure that the Electrode Unit is

slowly inserted all the way, and then lock

the lock switch to fasten the Electrode

Unit in place.

If cleaning the electrode needles does not improve the static elimination

performance, or the ion level alarm indicator frequently lights, a probable cause is

that the electrode needles have reached the end of their service life. Replace the

Electrode Unit.

An optional Electrode Unit for exchanging (OP-51407) is available.

START

/STOP

START

/STOP

BALANCE ION

FAN

COND

IONLEVEL

BALANCE ION

FAN

COND

IONLEVEL

Note:

4-3

Performing Maintenance on the Air Filter

When the blow rate of the static elimination blower has decreased or the air filter has got dirty, perform

maintenance on the air filter on the back panel of the Static Elimination Blower Unit.

Performing Maintenance on the Air Filter

1

Remove the air filter.

Pull the tab on the bottom of the air filter in the direction of

the arrow to remove the air filter together with the cover.

• Be sure to turn off the main power of the Static Elimination Blower Unit

before attempting maintenance. If not, there may be a risk of electric shock

or accidents.

2

Clean the air filter.

Clean the air filter of dust and dirt.

If the dirt is hard to remove, rinse the filter and dry completely

before use.

3

Attach the air filter.

Fit the air filter to the cover and attach them to the back

panel of the Static Elimination Blower Unit.

• Do not operate the blower without the air filter attached. This may cause

malfunction.

WARNING

CAUTION

5SPECIFICATIONS

5-1

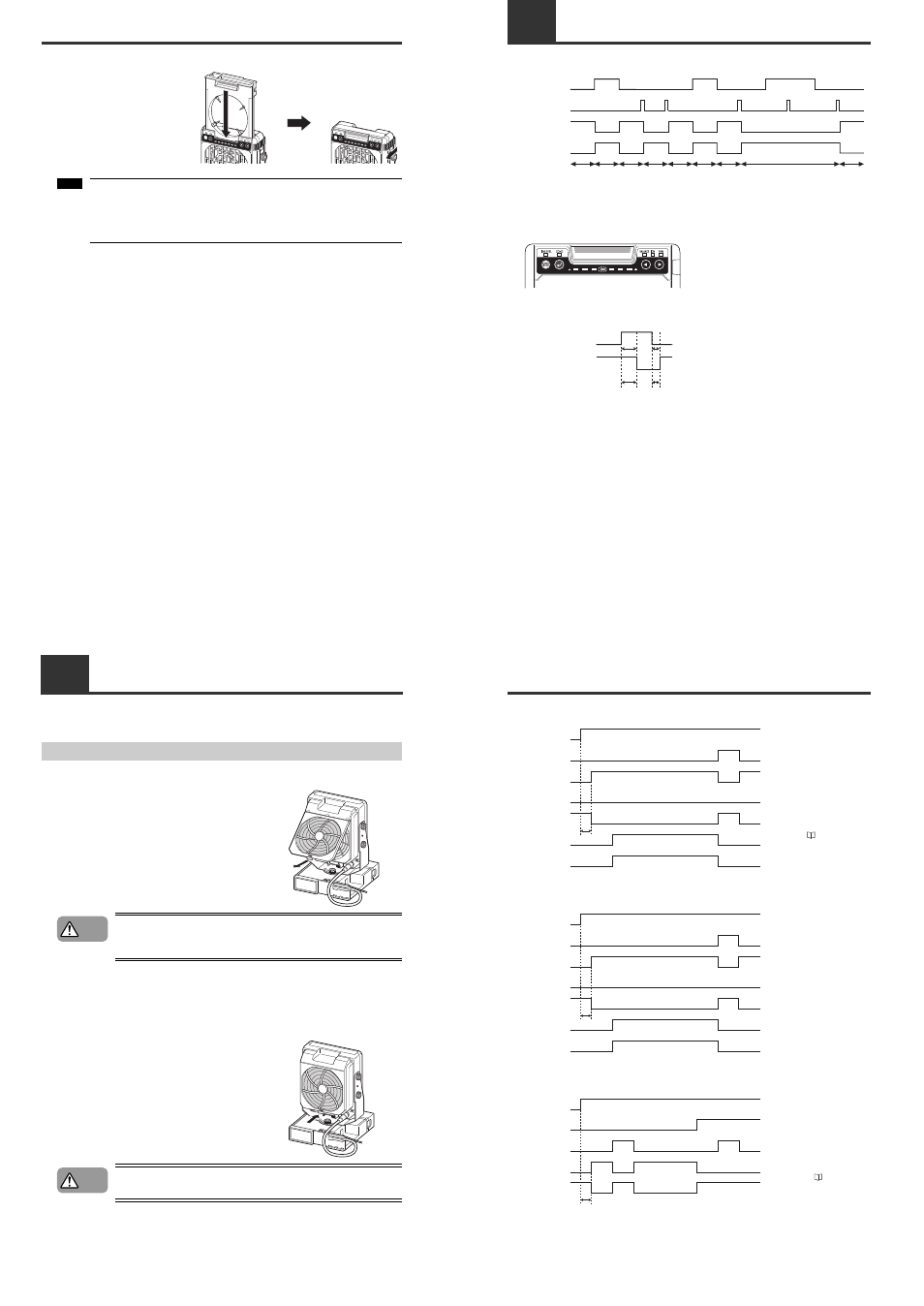

Timing Charts

■ Ion generation control timing chart

* When all the connected Static Elimination Blower Units stop static elimination, alarm output turns ON.

Indicator states when static elimination is OFF

■ Input response timing chart

Normally ON Normally OFF Normally ON

Forced OFF

Normally ON Normally OFF Normally ON

Forced OFF

Normally ON

Static elimination

stop input (terminal)

ON

OFF

Static elimination

stop input (static

elimination blower)

ON

OFF

Ion emission state

Unit indicator

Emitting

No

emissions

Alarm output

ON

OFF

Normal static elimination OFF

The center LED of the monitor lights in red.

Static elimination

stop input (unit)

ON

OFF

Ion emission

state

Emitting

No

emissions

5-1

Timing Charts

■ Ion level alarm output timing chart

■ Condition alarm output timing chart

■ Alarm output timing chart

Power

ON

OFF

Static elimination

stop input

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

Ion level

indicator

Max. 6.5 s

Blinking

OFF

Ion level alarm

output (N.O.)

ON

OFF

When the ion level alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

perform maintenance on the

electrode needles.

For details on electrode needle

maintenance, see "Performing

Maintenance on the Electrode

Needles" ( page 9).

Power

ON

OFF

Static elimination

stop input

ON

OFF

Alarm indicator

Blinking

OFF

Alarm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

Condition

indicator

Blinking

OFF

Condition alarm

output (N.O.)

ON

OFF

When the condition alarm is output,

removing the cause of the alarm can

restore the normal state. One way of

restoring the normal state is to

enhance the installation

environment.

Max. 6.5 s

Power

ON

OFF

Alarm indicator

ON

OFF

Static elimination

stop input

Blinking

OFF

Alarm output

(N.C.)

ON

OFF

Ion emission

Emitting

No

emissions

When the alarm is output, the

normal state can be restored by

performing one of the two available

restore methods depending on the

cause of alarm output.

For details on how to restore the

normal state, see "During an alarm

(levels 1, 2)" ( page 13).

Max. 6.5 s