5 other functions, Abnormal discharge detection function, 1 about maintenance – KEYENCE SJ-F300 Series User Manual

Page 10: About maintenance, 2 performing maintenance on the electrode needles, Performing maintenance on the electrode needles, Other functions

9

3-4

About Display Function

■ Condition alarm output function

This function causes the condition alarm output indicator to blink and an alarm signal (control output

[N.O.]) to output when ions are being absorbed by surrounding metal objects or when static elimination

performance is influenced by the installation environment (temperature, humidity, surrounding metal

objects, etc.).

Refer to

"Adjusting Condition Alarm Sensitivity" (page 7) for details about condition alarm

sensitivity setup.

• The display and output of condition alarm are automatically turned off when the

cause of the alarm condition is removed.

• In the case where the Static Elimination Blower Units are used in connection, the

alarm signal is output when alarm condition occurs in one of these units.

Condition alarm indicator

Condition alarm indicator

Tip

Note:

3-5

Other Functions

Abnormal Discharge Detection Function

To prevent trouble, this function causes the ion emission to stop when it detects abnormal discharging

caused by condensation on the electrode needle tips or adhesion of debris. At this time, the ion level

alarm indicator and the condition alarm indicator on the Controller Unit and all monitor LEDs on the

Static Elimination Blower Unit light up in red to inform you that an abnormality has occurred.

Refer to

"Table of Indicated States" (page 12) for indicated states of the Controller Unit.

About Function When Static Elimination Blower Units Are Used in Connection

In the case where the Static Elimination Blower Units are used in connection, the blow rates and the ion

balances of all the units can be adjusted collectively from the Controller Unit.

■ Blow rate collective adjustment function

This function allows the blow rates of all the units being in connection to be increased or decreased

collectively.

Increasing the blow rate enables static elimination from a wider area.

Refer to

"Adjusting Blow Rate of the Static Elimination Blower Unit" (page 7) for details about how to

adjust blow rate collectively.

■ Ion balance collective adjustment function

This function allows the ion balances of all the units being in connection to be adjusted collectively.

The SJ-F300 Series senses the charged amount of the target object by the I.C.C. function to

automatically control the emission (balance) of plus and minus ions.

The zero point, the point for reference for the I.C.C. function, is adjusted before shipment. However, in

some environments, the zero point sometimes drifts. If this reference zero point drifts, adequate static

elimination cannot be maintained. For this reason, it is necessary to adjust the SJ-F300 Series to a

desired zero point using this function.

Refer to

"Adjusting Ion Balance" (page 7) for details about how to adjust ion balance collectively.

4MAINTENANCE

4-1

About Maintenance

Maintenance must be performed periodically to ensure that the static elimination performance of the

SJ-F300 Series is fully demonstrated. For maintenance, be sure to thoroughly read the descriptions

under "Safety Precautions" (

page 1), and pay attention to the following points.

About Maintenance

• The SJ-F300 Series uses high voltage. Before starting maintenance, be sure to turn

the power OFF. Failure to do so may result in electric shock or malfunction.

• Do not directly touch the electrode needles.

Take care not to touch these needles even if

the power is turned OFF. Directly touching

these needles may cause personal injury.

When the SJ-F300 Series is used for a long period of time, the electrode needles become dirty due to

the adhesion of dust and dirt.

If the ion level alarm indicator lights, clean the electrode needles. If the electrode needles are used in a

dirty or dusty state, the static elimination performance can no longer be fully demonstrated, resulting in

accidents or malfunction. We recommend periodically cleaning the electrode needles (as a guideline,

once every two weeks in a regular operating environment though this depends on the installation

conditions).

If cleaning the electrode needles does not improve the static elimination performance, or the ion level

alarm indicator frequently lights, replace the Electrode Unit.

WARNING

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

4-2

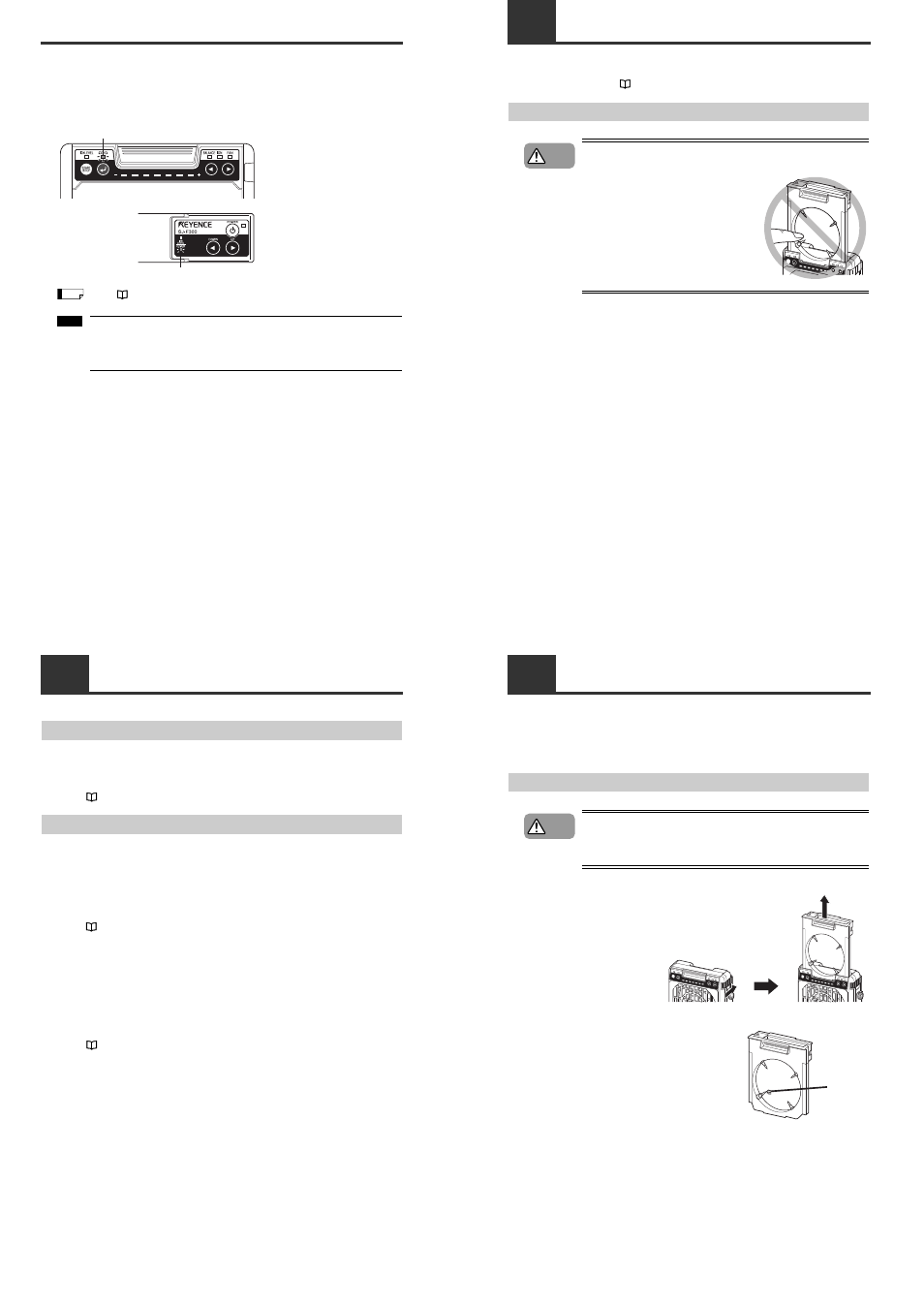

Performing Maintenance on the Electrode Needles

When the SJ-F300 Series is used for a long period of time, the electrode needles become dirty due to

the adhesion of dust and dirt.

If the electrode needles are used in a dirty or dusty state, the static elimination performance can no

longer be fully demonstrated, resulting in accidents or malfunction. Be sure to periodically perform

maintenance on the electrode needles.

Performing Maintenance on the Electrode Needles

• Before removing the Electrode Unit, turn the SJ-F300 Series OFF.

• Do not directly touch the electrode needles with your hands. Doing so may

cause personal injury. Pay attention to this when performing maintenance

on the electrode needles.

1

Remove the Electrode Unit.

Unlock the lock switch on the Static

Elimination Blower Unit, and pull out the

Electrode Unit in the direction of the

arrow.

2

Clean the electrode needles.

Clean the electrode needles with a cotton wool

bud moistened with alcohol.

WARNING

START

/STOP

BALANCE

ION

FAN

COND

IONLEVEL

BALANCE

ION

FAN

COND

IONLEVEL

START

/STOP