Installing the air tube – KEYENCE GT2-500 Series User Manual

Page 5

5

GT2-500-M-E

1

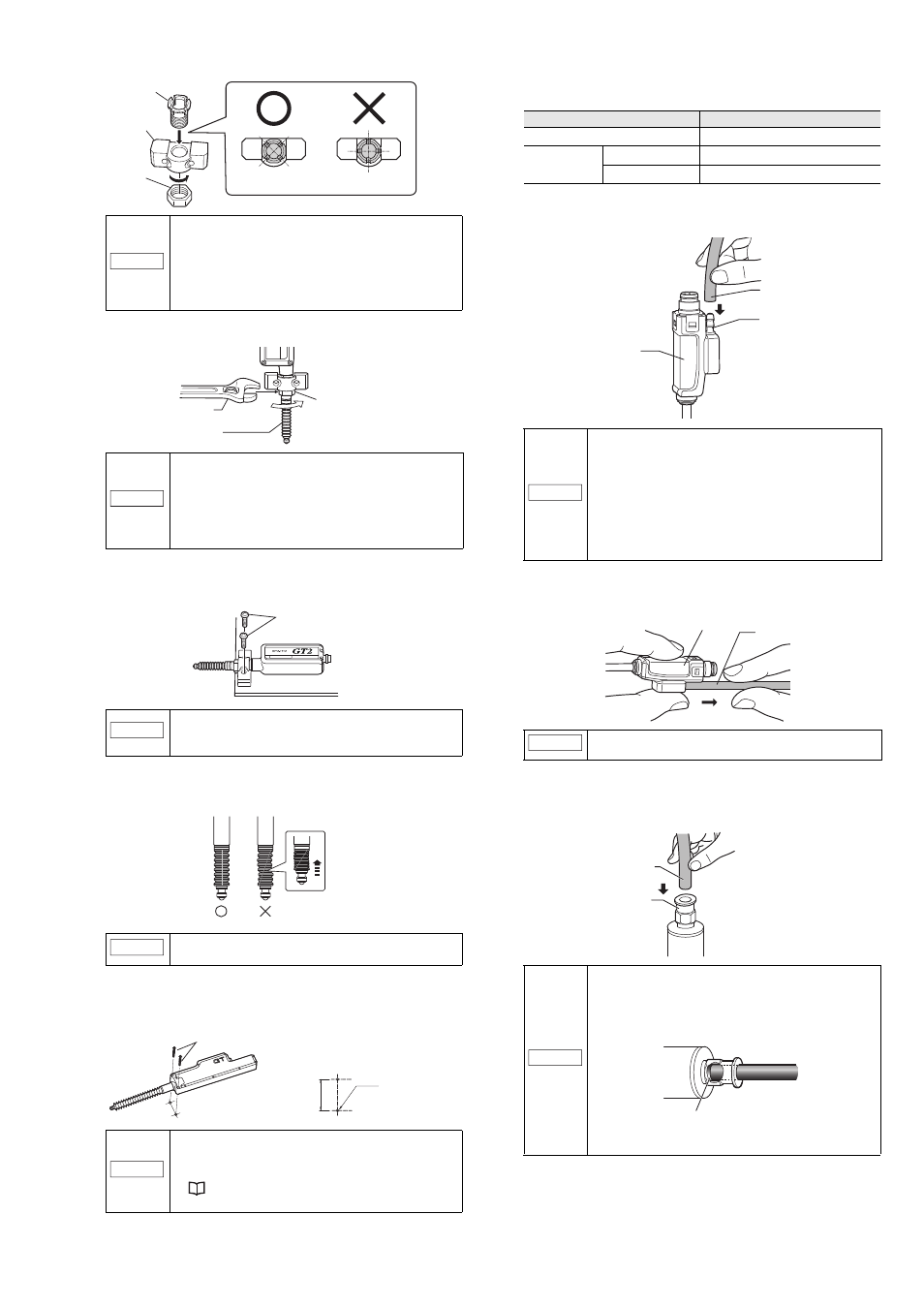

Insert the tightening sleeve into the mounting bracket from the side

with a depression, and loosely tighten with the nut.

2

Insert the sensor head into the tightening sleeve, and tighten the nut

with a wrench.

3

Secure the sensor head with M4 screws.

Mount the sensor head with the model label on top. For GT2-P12K(L)/

P12(L)/PA12K/PA12, mount so that the head indicator is on top.

4

Rotate the dust boot so that the side line is straight. (Models other

than GT2-PA12K/PA12)

Check with the spindle pushed in.

● Mounting to the mounting holes

The mounting holes on the side of the GT2-H32(L)/H50/A32/A50

unit can be used to install to the side of a table or other surface.

■

Installing the Air Tube

● Compatible air tube

Use a tube with the following specifications.

● How to Attach/Detach the Air Tube (GT2-PA12K/PA12)

•

Attaching the air tube

Insert the air tube into the air supply hole on the relay connector.

•

Detaching the air tube

To detach the air tube, pull the air tube in the direction of the arrow,

as indicated in the figure below.

● How to Attach/Detach the Air Tube (GT2-A12K(L)/A12(L)/A32/A50)

•

Attaching the air tube

Feed the tubing into the socket until it bottoms out (about 1/2").

The socket will ensure a tight seal around the tubing.

NOTICE

• If the sleeve is inserted from the wrong side, the

sensor head cannot be secured.

• Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

• Head mounting bracket B cannot be used in

combination with head mounting bracket C (OP-

84396) or head mounting bracket D (OP-84327).

NOTICE

Tightening the nut while fixing the sensor head may

lead to damage.

• Apply a tightening torque of 5 to 7 N m (the

recommended tightening torque is 5 N m). Use the

wrench that fits the width of the nut.

• Care must be taken not to damage the dust boot

when tightening.

NOTICE

• Never apply tightening torque over 1.4 N m.

• Care must be taken not to damage the dust boot

when tightening.

NOTICE

If the dust boot is not straight, it becomes easier to

damage when the spindle is moved.

NOTICE

• Roughness of the mounting surface may cause the

sensor to tilt, and sufficient accuracy may not be

obtained. When performing a high-accuracy

measurement, use a jig to mount the sensor head.

"Mounting directly to the jig" (page 4)

• Apply tightening torque between 1.2 and 1.5 N m.

Tightening sleeve

Mounting bracket

Nut

Notice the correct angle of the tightening sleeve.

Nut

Wrench

Dust boot

M4 screws

Mounting illustration

M4 tap

23

± 0.15 mm

M4 screws

(Mounting hole dimensions)

Item

Description

Recommended tubing material

Urethane

Tubing size

Outer diameter

4 mm

Inner diameter

2.5 mm

NOTICE

• For best results, cut the end of the tube at a right

angle, and ensure that the outer perimeter is not

damaged, and that it still maintains a circular cross

section.

• If the tube is not properly inserted, air leakage may

result.

• After attaching, pull on the tube to make sure it is

secure.

• Use a urethane tube. Make sure it also has a

bending radius of at least 50 mm.

NOTICE

Before detaching the tube, be sure to stop any air flow.

NOTICE

• For best results, cut the end of the tube at a right

angle, ensure that the outer perimeter is not

damaged, and that it still maintains a circular cross

section.

• If the tube is not properly inserted, air leakage may

result (see figure below).

• After attachment, pull on the tube to make sure it is

secure.

Air tube

Air supply hole

Relay connector

Relay connector

Air tube

Air tube

Coupling socket

Tube end