Point calibration (operation modes: f-1, a-1, a-2), Point area calibration (operation mode: f-2) – KEYENCE GV Series User Manual

Page 5

5

GV-IM-E

z

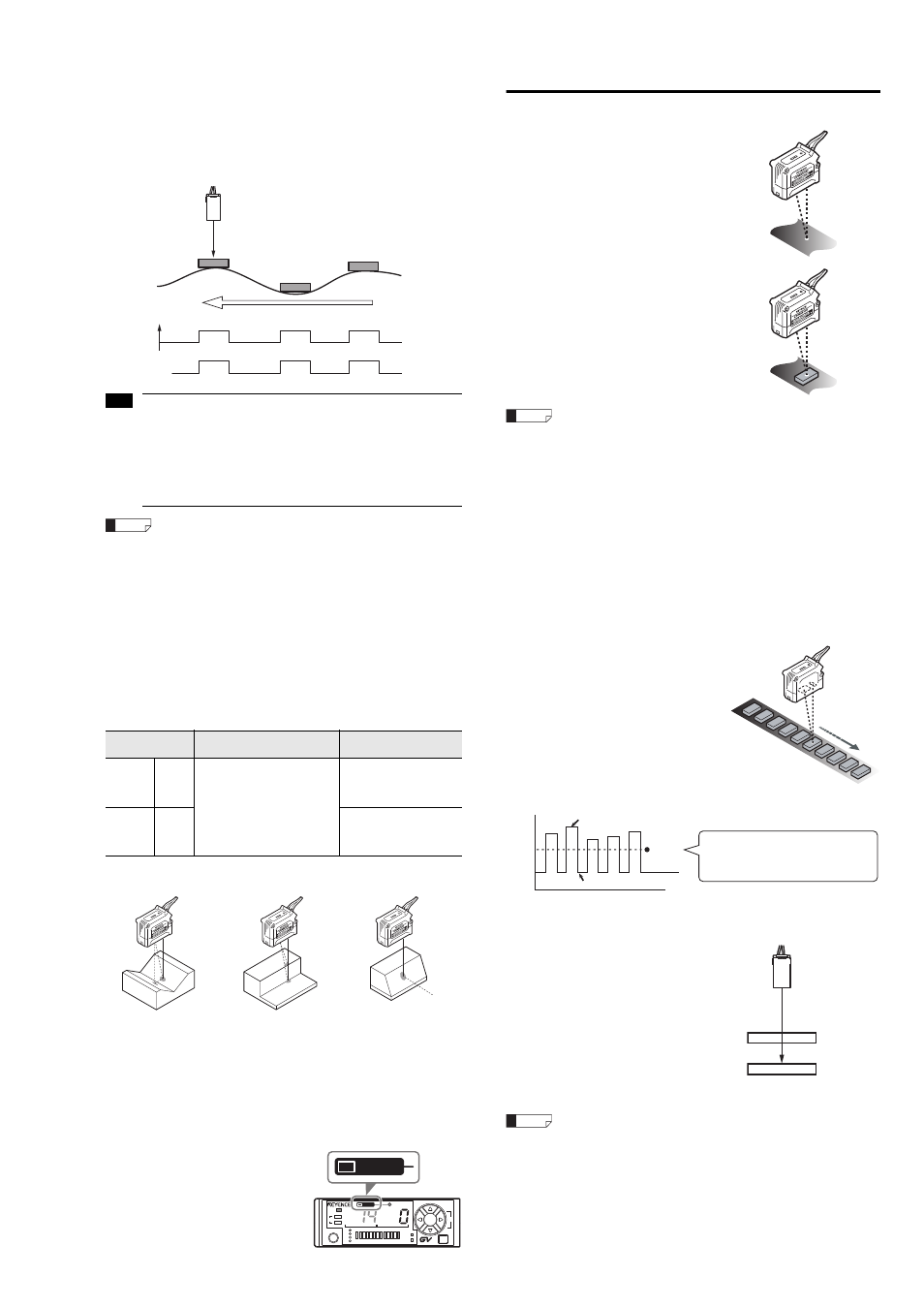

Edge hold mode (A-1 mode)

This operation mode is suitable for detecting workpieces on a conveyer or

detecting workpieces with waving backgrounds. It ignores slow distance

changes and only detects workpieces (sudden changes in height).

When height differences greater than the setting value are detected (low areas

become high), the value at the detected time are held and displayed, and

control output starts.

If the difference is small and does not exceed the setting value, the display stays as 0.

When height differences greater than the setting value are detected (high areas

become low), detection value becomes 0 and control output is stopped.

• When edge hold mode (A-1 mode) is selected, edge hold mode only

operates on channel 1. Channel 2 operates under distance

measurement mode (F-1 mode).

• If the edges are gentle (such as spherical or tilted workpieces), this

mode may not be able to detect workpieces or may output the value

incorrectly.

• Send the workpiece past the sensor head so that the area for

detecting height differences is parallel to the sensor head. See

"When detecting uneven workpieces" (page 3).

•

When a detection value is being held, press and hold the [Up] and

[Down] arrow buttons at the same time to set the current value to 0

(regardless of the shift target value) and to turn off output. The

current value for channel 2 changes to 0 as well.

•

If the external input function is set to "SFt" and the external input

(pink line) is turned on, the control output turns off and the current

value becomes 0. (When channel 2 is selected, the current value

becomes 0 as well. Turning the laser emission stop input on and

off performs a similar action, but it only changes the current value

of the channel to 0.)

Reference surface detection (DATUM) method (Application)

This method memorizes the background (reference surface) and uses it to

perform comparator output when there is a workpiece (when the state differs

from the reference surface).

The reference surface detection (reference surface calibration) can only be

used on Channel 1 of operation mode F-1/F-2.

Use the reference surface (DATUM) detection method in the following situations:

During reference screen (DATUM) detection, the background is memorizes as

references. During the unstable situations noted above, a workpiece is judged

as present when the detected surface is different from the background.

This makes stable detection possible even when using workpieces with

unstable shapes.

The reference surface (DATUM) detection indicator lights up when using reference

surface detection after performing reference surface (DATUM) calibration.

Configuring the sensitivity setting for distance

detection method

2-point calibration (operation modes: F-1, A-1, A-2)

1

Press the [SET] button once without

a workpiece in place.

The current value without the workpiece is

read.

2

Place a workpiece in the detection

position, and quickly press the [SET]

button once again.

The setting value is calculated as the mean

value between the value obtained in step 1

and the value obtained in step 2.

This concludes 2-point calibration and the

sensor returns to the detection state.

If there is very little difference between the values obtained in Step 1 and

Step 2, then "---" flashes in the setting value display area after

calibration is complete. The setting value is still updated.

Maximum sensitivity setting (operation modes: F-1, A-1, A-2)

1

Press and hold the [SET] button for at least three seconds without a

workpiece in place.

2

Release the [SET] button when "SEt" flashes on the display.

This concludes maximum sensitivity calibration and the sensor returns to the

detection state.

Full auto calibration (operation modes: F-1, A-1, A-2)

This method performs calibration while the target is moving.

1

Press and hold the [SET] button for at

least three seconds while the target

workpiece is passing through the

detection area for the sensor.

The sensitivity is set according to the

detection value while the [SET] button is

pressed.

2

Release the [SET] button when "SEt"

flashes on the display.

This concludes calibration and the sensor

returns to the detection state.

2-point area calibration (operation mode: F-2)

1

Place a workpiece on the upper limit

that you want the sensor to detect,

and press the [SET] button once.

That upper limit becomes the HIGH setting

value.

2

Place a workpiece on the lower limit

that you want the sensor to detect,

and press the [SET] button once.

That lower limit becomes the LOW setting

value.

If there is very little difference between the values obtained in Step 1 and

Step 2, then "---" flashes in the setting value display area after

calibration is complete. The setting value is still updated.

Operation

mode

Description

Changes to the

setting value

General

F-1

Turns on control output when

the detected surfaces is not the

same as the memorized

reference surface.

The current value for the

memorized surface is forcibly

set to 0. (The display is

common for channels 1 and 2.)

The setting value can be

configured around 0.

Individual setting values

cannot be changed.

Special

F-2

The setting value can be

configured around 0.

Individual setting values

can be adjusted.

Detection

value

Control

output

ON

OFF

0

Note

Reference

Influence of diffuse

reflection

(Multiple reflection)

Split spot

(Multiple reflection)

Insufficient light

intensity

CLP

OUT

LASER

TIM

BANK

SET

SEL

MODE

1

2

1

2

1

spot

DATUM

DATUM

series

Reference

Detection value

Setting

value

Time

MAX

MIN

The value is set to the mean value

between the maximum and minimum

values detected while the [SET] button is

pressed down.

Upper limit

Lower limit

Reference