5 replacement of check valves – BUCHI SpeedExtractor E-916 User Manual

Page 82

8 Troubleshooting

82

SpeedExtractor E-916/E-914 Operation Manual, Version D

8.1.5

Replacement of check valves

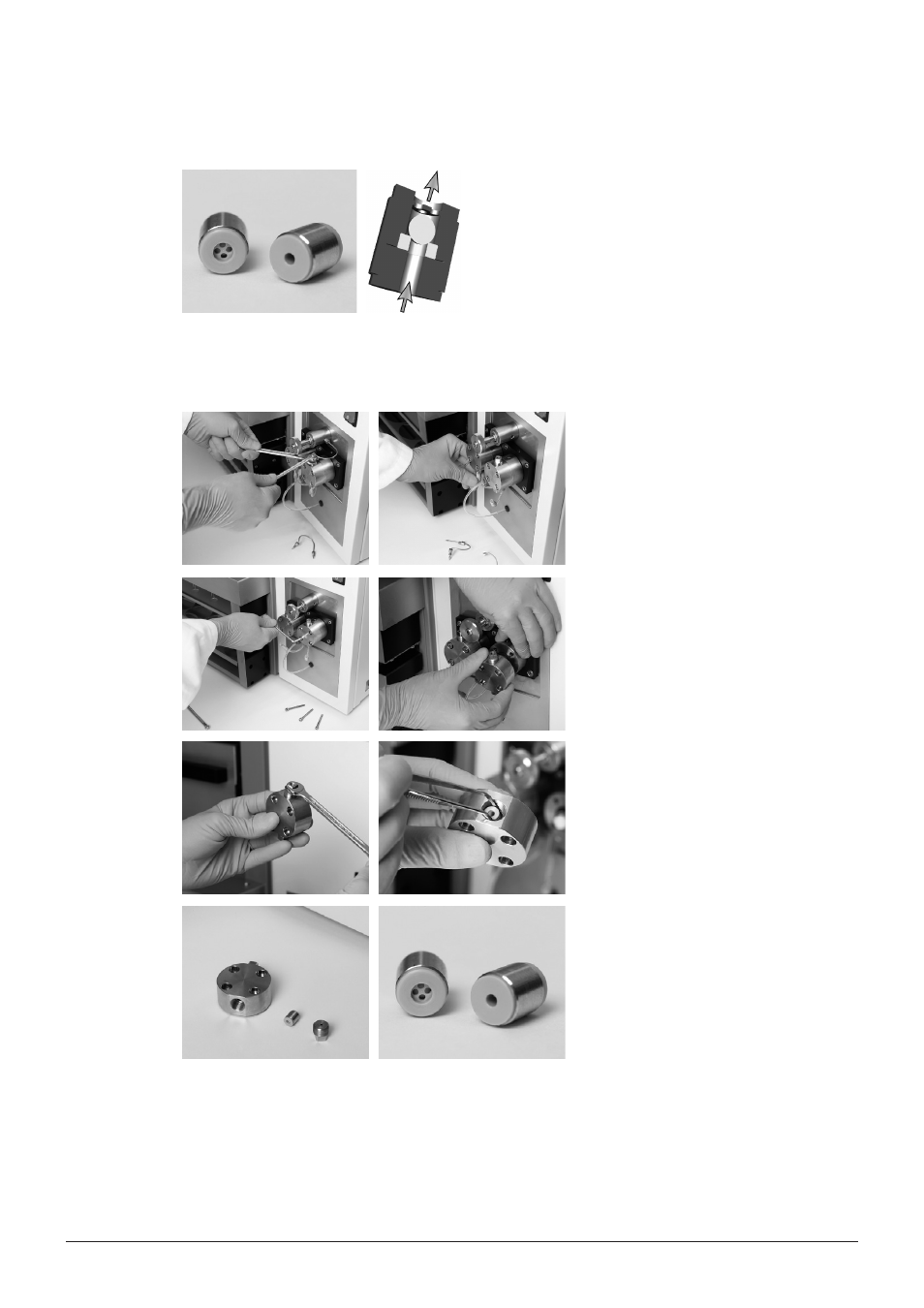

The principle of a check valve is a precise ball and seat

located in a casing of PEEK material with stainless steel

reinforcement. By a stream of liquid the ball is pressed

down to the seat, thus creating a seal. With respect to

high pressures in the pump, any minute impurity stuck

on the surface of the ball or the seat causes pressure

fluctuation, or the pump fails to start at all. If you do

not succeed in correcting these problems by repeated

purging, it is necessary to replace or clean the valves.

Replacement of the outlet and inlet check valve

• Screw out the nut on the valve

holder using a 1/4” and 8 mm

spanner wrench, and take off the

capillary.

• Unscrew the fittings of the pump

inlet lines.

• Unscrew the four nuts from the

head using a 3 mm allen wrench.

• Carefully remove the pumping head.

• Unscrew the valve holder using a

8 mm spanner wrench.

• Remove the valve from the pumping

head using tweezers.

• Insert the new valve in the same

direction, i.e. with the four holes

upwards.

• Proceed similarly with the inlet

check valve at the bottom side of

the pump head. The four holes on

the valve should always point in the

direction of the pumping head, so

that the inserted valve has a visible

part with one hole.

• Proceed in reverse order to reas-

semble the pump. Tighten all nuts

and, when starting the pump, check

whether any connection is leaking.

• Attempt to clean the valves in

acetone using ultrasound (or in

another solvent), which dissolves

the buffers you have been using.