4 the pump is not aspirating properly – BUCHI SpeedExtractor E-916 User Manual

Page 81

8 Troubleshooting

81

SpeedExtractor E-916/E-914 Operation Manual, Version D

8.1.4

The pump is not aspirating properly

NOTE

When the pump is running but the solvent is not aspirated check first if the right solvent port is

selected (see section 6.2.6).

A new pump or a pump that has been out of operation

for a long time may sometimes be difficult to start. The

cause is a dried out solvent on the check valves and

air bubbles stuck on the pumping mechanism. Both

causes result in pressure fluctuations, or solvent intake

fails completely.

• Visually inspect the connections, lines, and filter of

the solvent reservoir. Replace items if necessary as

described in section 6.2.1 and 7.3.1.

• If the pump is still not purging properly, assistance

by means of a syringe is sufficient in most cases.

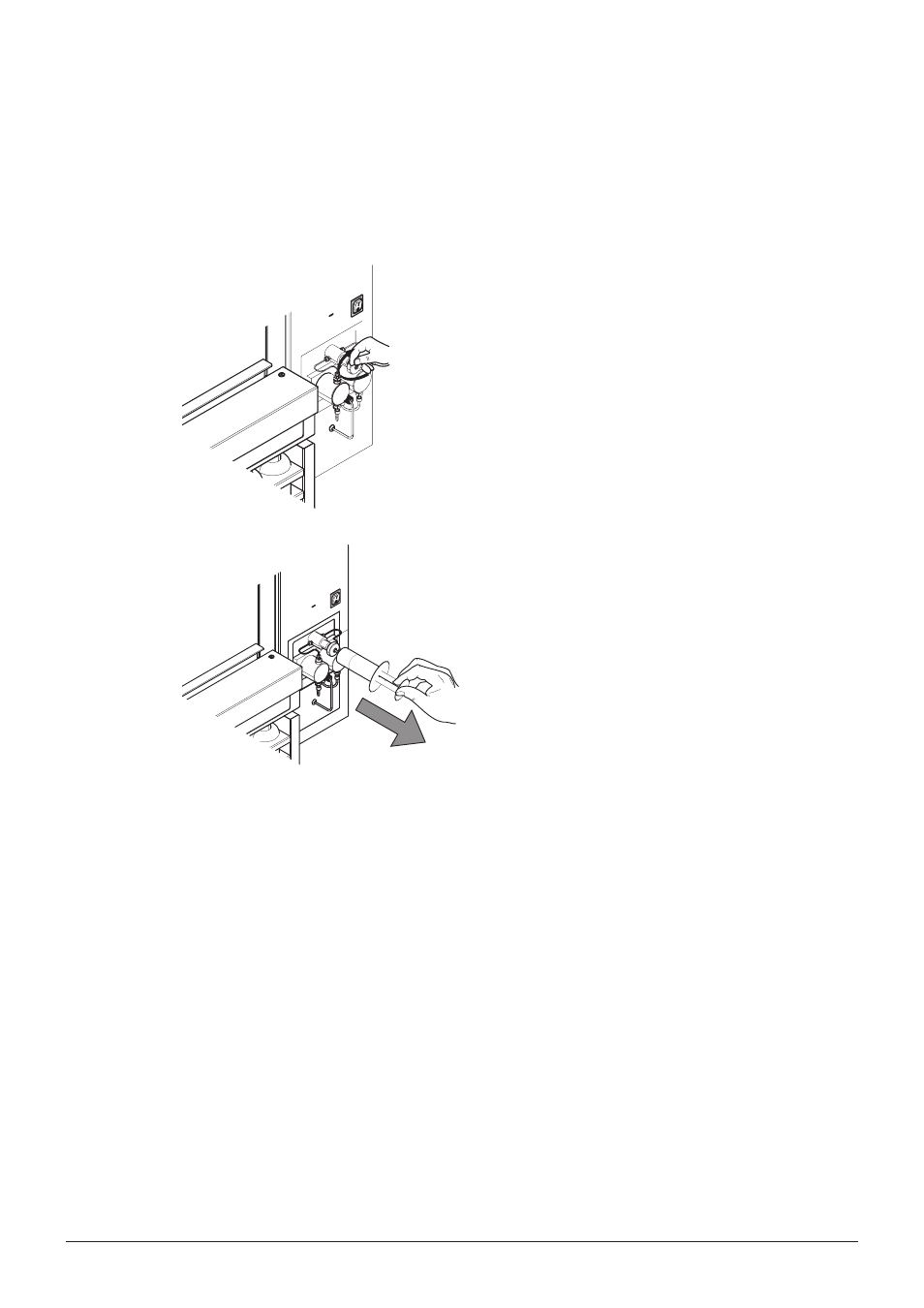

Slacken the by-pass valve. Turning by 90° counter-

clockwise is sufficient.

• Suck up a solvent using a plastic syringe until the

pump stops producing bubbles. Empty the syringe,

attach it again, start the pump, and watch to see

whether the pump sucks regularly and all bubbles

have been eliminated. Once the pump is working

properly, close the by-pass valve and keep the

pump running for a while.

• If pumping is still irregular, leave the pump running

for approximately 10 minutes and observe whether

the pump pumps regularly and all bubbles have

been eliminated. If the problems persist, repeat

purging (with the by-pass valve slackened).

• If the problem still persists equip the syringe with a

pointed cannula that fits into the intake FEP tube

(ID 1/16”) and fill the syringe with the solvent used

for the extraction method. Press some solvent into

the tube while the pump is running and dip it into

the solvent reservoir as soon as the pump begins

aspirating.

NOTE

The syringe P/N 034882 is made of polypropylene and is therefore not compatible with halogenated

solvents (i.e. dichloromethane) and acids.