BUCHI Nano Spray Dryer B-90 User Manual

Page 70

6 Operation

70

B-90 Operation Manual, Version B

6.5

Starting a spray drying process

System preconditions

All system items must be correctly installed according to the kind of set-up, see section 5 for more

information. Carry out a final installation check (see section 5.9) before every spray drying process.

See also section 2.5 “Product safety” for general warnings.

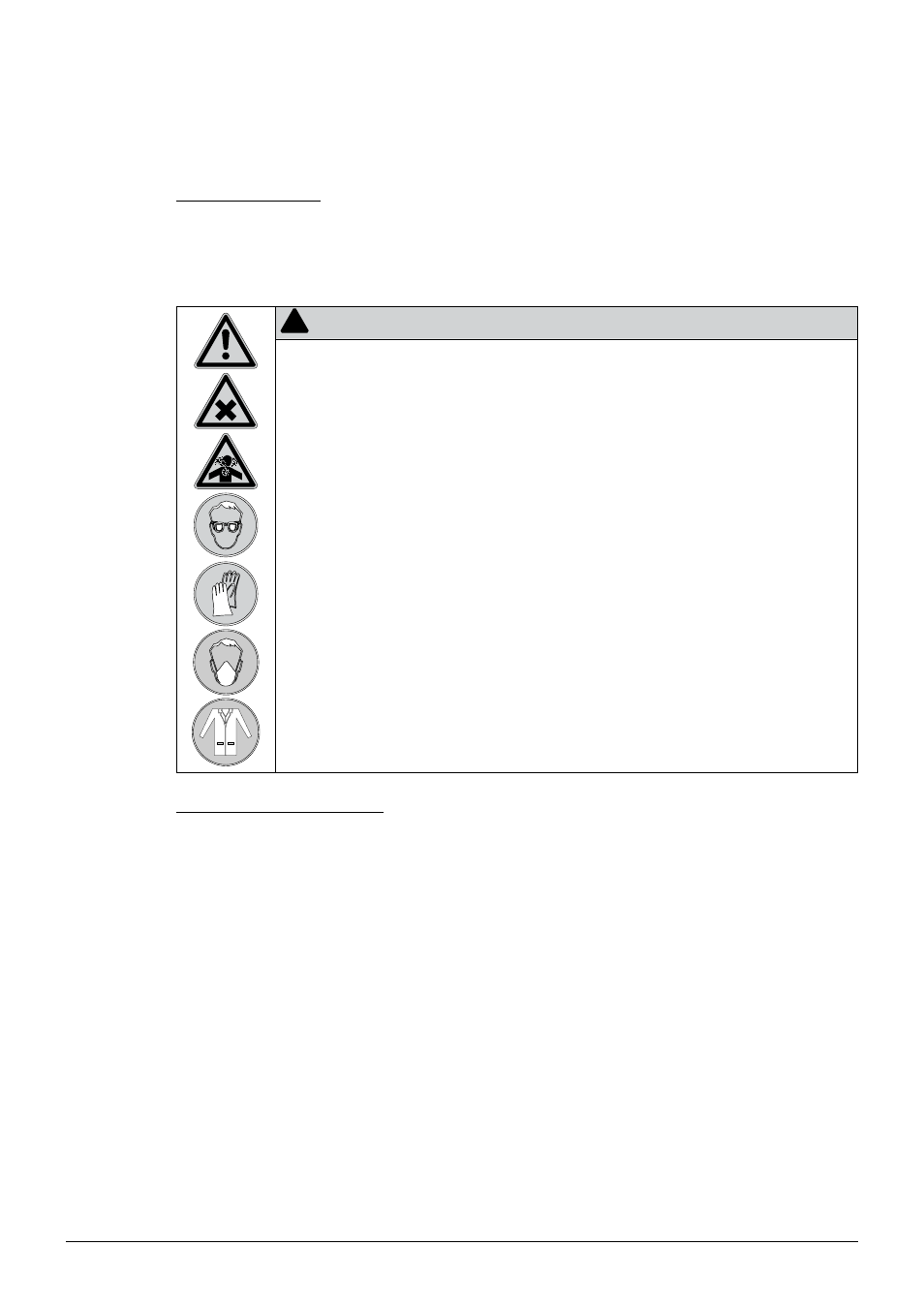

!

Danger

Death or serious poisoning by inhalation or incorporation of dried particles during spray process.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Check for proper sealing before use

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

Starting a spray drying process

1. Switch on the instrument. After the automatic self check, the operating mode is activated.

2. Switch on all other devices if installed in the current configuration.

3. Set the drying gas rate to a reasonable flow of about 70–150 liter/min with the external gas regu-

lator (when using compressed gas) or adjust the frequency controller when using the Aspirator

(set a rotational frequency between 30–40 Hz).

4. Read the relative inside pressure (typical pressure range 30 mbar to 60 mbar).

5. Select the desired inlet temperature (typical setting between 80 °C to 120 °C).

6. Switch on the heater by pressing the “Heat” button and wait until the system has reached

stationary temperature conditions (typically after 5 to 10 min.).

7. Switch on the peristaltic pump by pressing the “Pump” button.

8. Select the relative spray rate (typically 100 % to achieve maximum throughput).

9. Press the “Spray” button to start the spray process.

The spray process starts and the electrical field in the particle collector is turned on.