BUCHI Nano Spray Dryer B-90 User Manual

Page 60

5 Putting into operation

60

B-90 Operation Manual, Version B

5.9.2

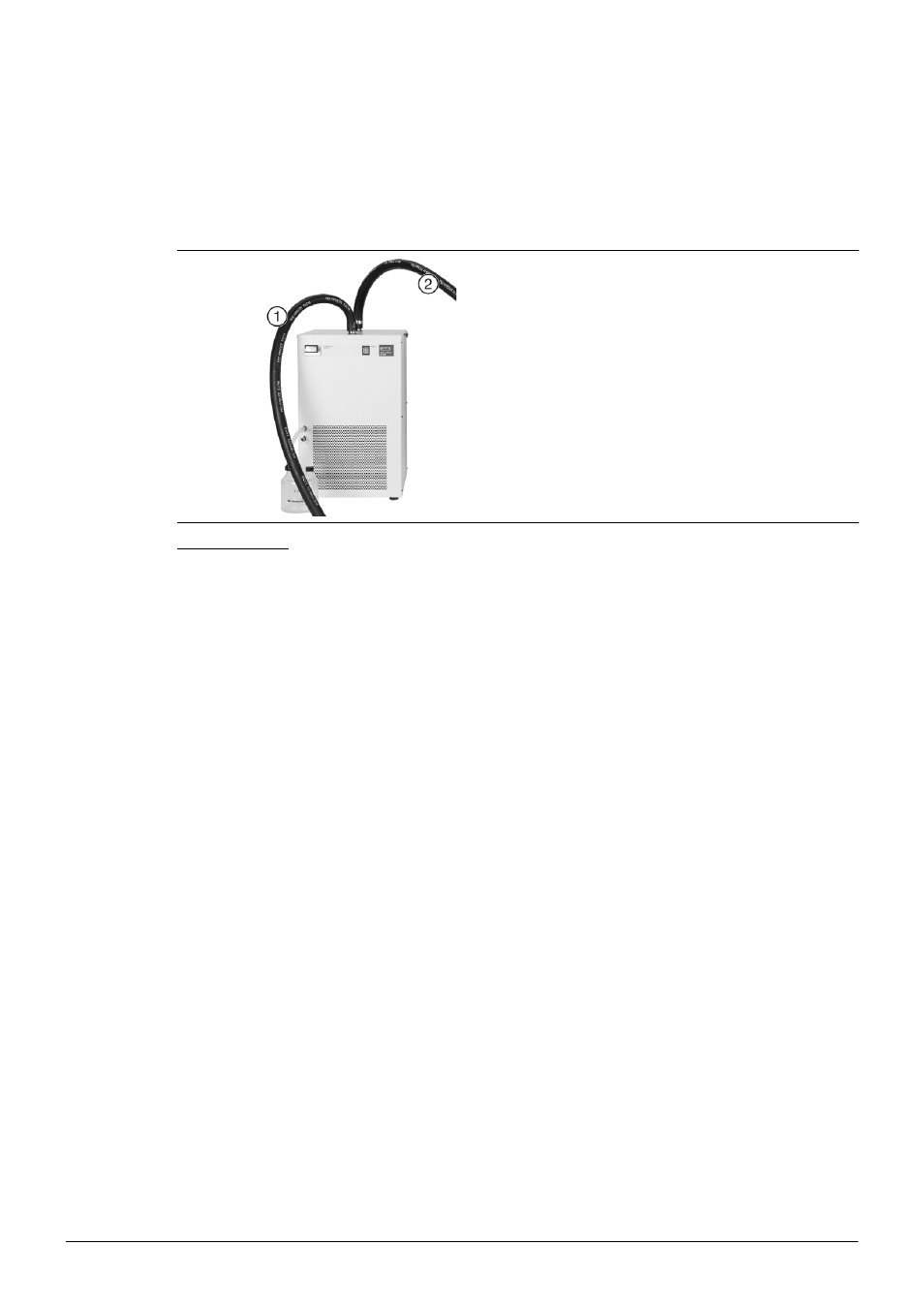

Dehumidifier B-296 in ‘closed loop’ configuration with out Inert Loop B-295

When mixtures of organic solvents and water (with less than 50 % solvents) are being processed in

‘closed loop’ configuration, the use of the Dehumidifier B-296 in combination with a heat exchanger is

highly recommended. The optional heat exchanger increases the condensation performance and can

additionally reduce the residual solvent/water content of the spray dried material.

a Inlet tubing B-296

b Outlet tubing B-296

Installation steps

1. Disconnect the power cord from the mains and depressurize all system parts.

2. Place the Dehumidifier B-296 next to the Nano Spray Dryer B-90 and the Aspirator.

3. Connect the tubing b from the outlet (labelled on the enclosure) of the Dehumidifier B-296 to the

gas inlet of the Aspirator (see section 5.6.1; connector a). An additional tube is needed.

4. Connect the Aspirator outlet to the inlet of the Nano Spray Dryer B-90 (see section 4.10,

connector h).

5. Connect the tubing from the Nano Spray Dryer B-90 outlet (see section 5.6.1; connector b) to

the inlet a of the Dehumidifier B-296 (labelled on the enclosure). An additional tube is needed.

6. Use hose clamps to fix all Polypress tubings.

7. Connect the power cord to the mains. The device can now be switched on.

5.9.3

Adsorption column installation

If mixtures of organic solvents and water are used, the Dehumidifier B-296 is strongly recommended

for a ‘closed loop’ configuration. The Dehumidifier B-296 removes the water from the drying gas

before entering the Inert Loop B-295. This separation prevents water from freezing in the Inert Loop

B-295 and potential damage of the heat exchanger.

NOTE

The upgrade kit for the Inert Loop B-295 has to be installed according to the chapter 5.8.1