BUCHI Nano Spray Dryer B-90 User Manual

Page 26

4 Description of function

26

B-90 Operation Manual, Version B

Optional drying gas recycling in ‘closed loop’ mode:

In ‘closed loop’ mode of the Nano Spray Dryer B-90 Advanced the “Drying gas outlet” i is connected

via the Inert Loop B-295 or Dehumidifier B-296 and Aspirator to the “Drying gas inlet” a.

4.1.2

Spray drying process overview

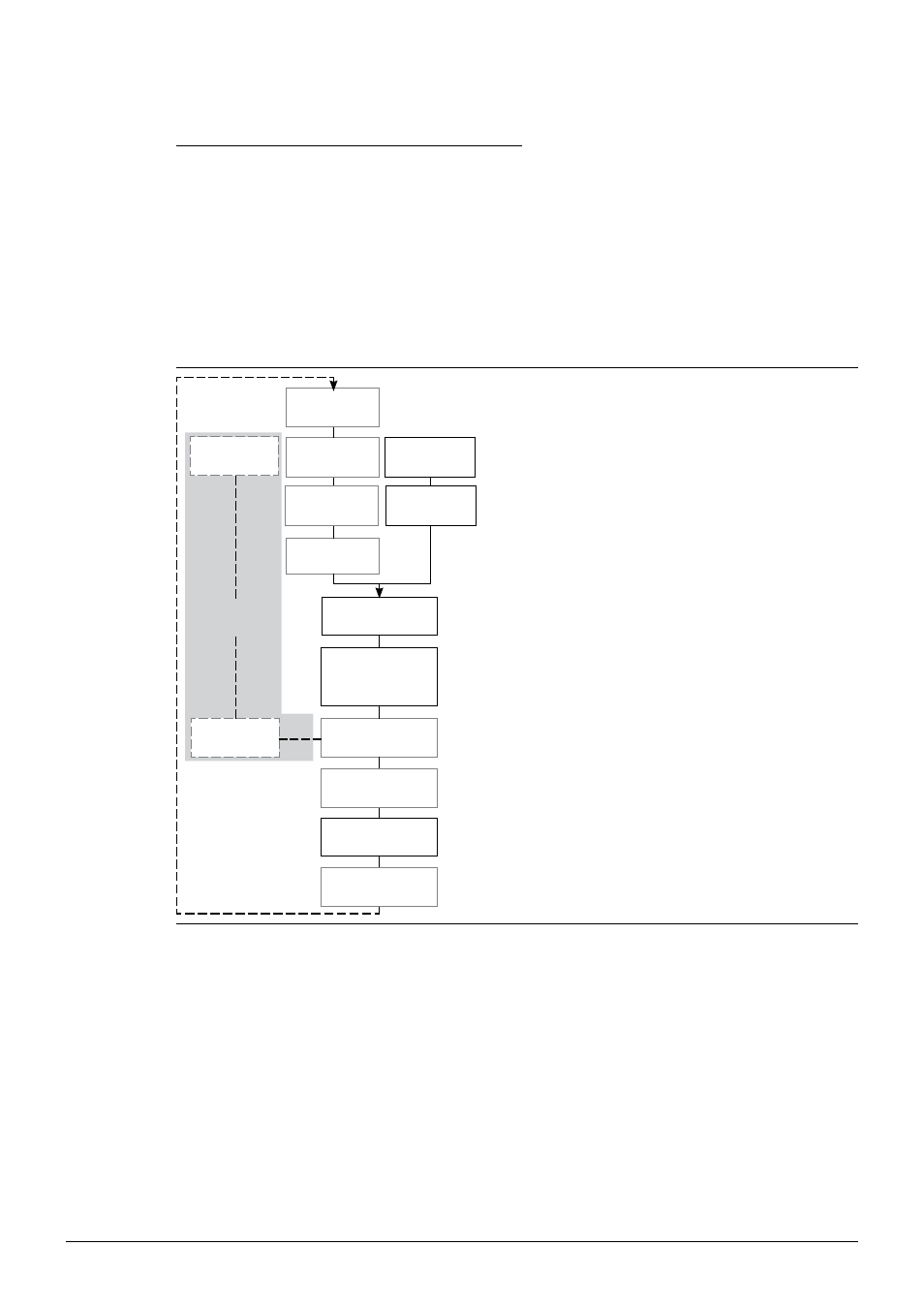

The drying process takes place inside the drying cylinder. A drying gas flow is established and tiny

droplets of sample material are injected by the spray head. The sample material is dried by the hot

gas. Because of the tiny particle size, an electrical field of sufficient power is needed to retrieve

the particulate material from the drying gas flow. The following scheme informs about the different

processing stages in general.

Drying gas inlet

Flow meter

Electrical heater

Inlet temp. sensor

c

Drying cylinder

d

Electrical particle

collector

Rel. pressure sensor

Outlet temp. sensor

e

Outlet filter

Drying gas outlet

Oxygen sensor

Gas regulator

a

Feed pump

b

Spray head

safety loop

a The “Feed pump” constantly feeds the “Spray head”

with liquid sample material.

b The “Spray head” produces finest droplets and in-

jects them into the “Drying cylinder”.

c The heated drying gas enters laminar from the top

into the “Drying cylinder”. Consequently, the injected

drops of sample material are gently dried to solid

particles.

d The “Electrical particle collector” retrieves the dried

solid particles by an electrostatic field.

e The exhaust gas leaves the spray dryer via the “Out-

let filter” which retains free particles from the gas.