Ab (optional) c, 4 drying air generation – BUCHI Nano Spray Dryer B-90 User Manual

Page 28

4 Description of function

28

B-90 Operation Manual, Version B

4.4

Drying air generation

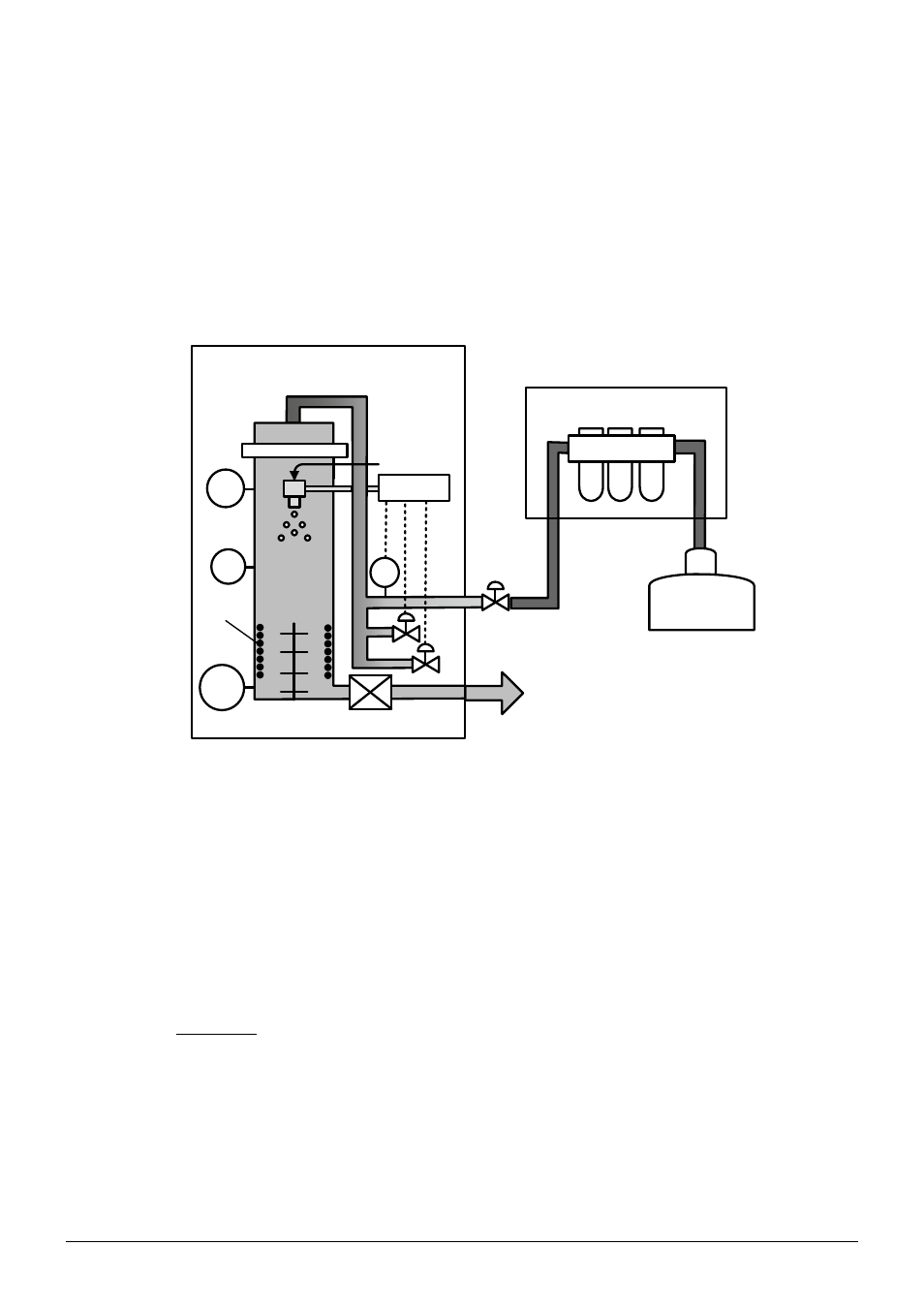

In ‘open loop’ mode the required drying air can be either supplied by an in-house compressed air

supply, an oil-free compressor or a BUCHI Aspirator (see section 3.1.4, Optional accessories).

4.4.1

Compressed air supply

In ‘open loop’ configuration, compressed air is used as standard drying gas. The air maintenance unit

(order no. 004366) is additionally recommended to assure gas of clean, dry and oil free quality. A pres-

sure regulating valve is required to match the instruments input pressure value.

Air maintenance unit

Exhaust gas

Nano Spray Dryer B-90

Basic

T

OUT

P

Outlet filter

FI

Compressed

air

T

IN

Control

Feed

Product

a

b (optional)

c

a Compressed air source

b Optional air maintenance unit

c Pressure regulating valve

4.4.2

Aspirator in blowing mode

If there is no compressed air available in the laboratory, the BUCHI Aspirator unit with inlet filter (order

no. 051700) can be used to establish the required drying air flow rate. The Aspirator can be connected

directly to the inlet of the Nano Spray Dryer B-90 without a pressure regulating valve. In case of higher

ambient humidity use the Dehumidifier B-296 to achieve dry air.

NOTE

If the humidity of the air is too high, the current in the particle collector could be too low.

Air inlet filter

The air inlet filter is required to avoid any contamination of the instruments by fine particles in the lab

environment. It is to be connected to the inlet of the Aspirator, so the instrument aspirates filtered

ambient air. The filter consists of a stainless steel grid for outer protection and an ultra filter based on a

glass fibre textile (filter class S according to DIN 24184).