Cb a, De f – BUCHI Nano Spray Dryer B-90 User Manual

Page 57

5 Putting into operation

57

B-90 Operation Manual, Version B

5.8.1

Main device installation

During the process, a constant inert gas flow (N

2

or CO

2

) is fed into the gas loop to refresh the used

drying gas. This constant gas feeding requires an exhaust gas output to balance the pressure inside

the gas circuit, thereforee the Inert Loop B-295 is equiped with a hose connection for the exhaust gas

at its right side. The use of inert gas requires additional safety measures. The upgrade set for the Inert

Loop B-295 (order no. 051783) is required to work in ‘closed loop’ operation with Nano Spray Dryer

B-90 Advanced. The set includes a back pressure check valve, hose connectors and compressed gas

tubing for CO

2

and N

2

.

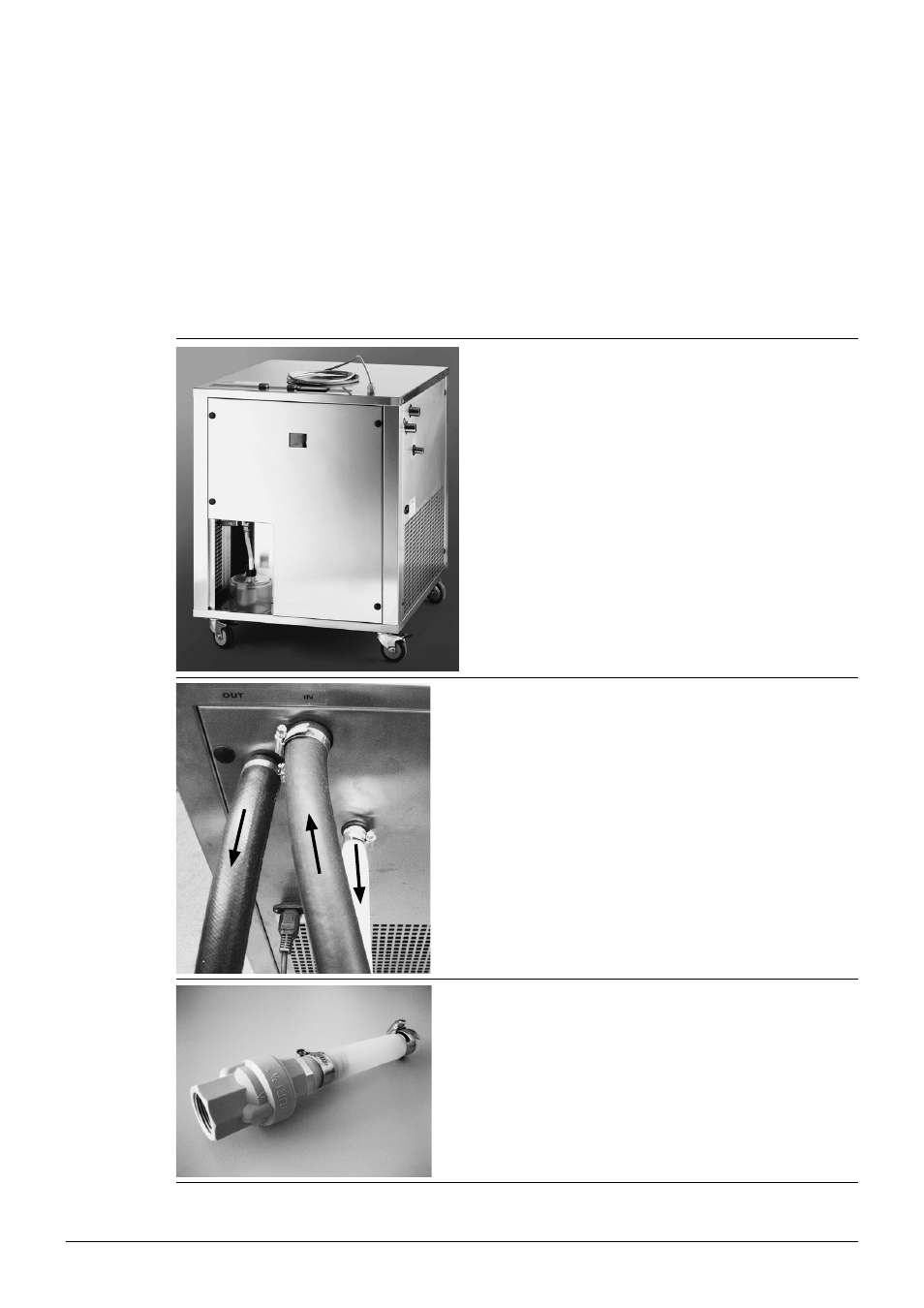

c

b

a

a Communication cable to the Nano Spray Dryer B-90

Advanced (see section 4.10; socket c)

b Oxygen concentration display window

c Solvent condensate collector

The Inert Loop B-295 has transport wheels mounted

and can be placed next to a fume hood, near the Nano

Spray Dryer B-90 Advanced in the lab.

The communication cable a is part of the oxygen

safety loop. When the oxygen content reaches 6 % the

spray drying will be interrupted and an error message

will be displayed at the Nano Spray Dryer B-90

Advanced.

d

e

f

d Gas outlet towards gas inlet of the Aspirator (see

section 5.5.2)

e Gas inlet connected to the gas outlet of the Nano

Spray Dryer B-90 Advanced

f Exhaust gas outlet towards check valve g

g

g Check valve with exhaust gas tube

(to connection f )