BUCHI Nano Spray Dryer B-90 User Manual

Page 47

5 Putting into operation

47

B-90 Operation Manual, Version B

5.4.2

Spray head installation

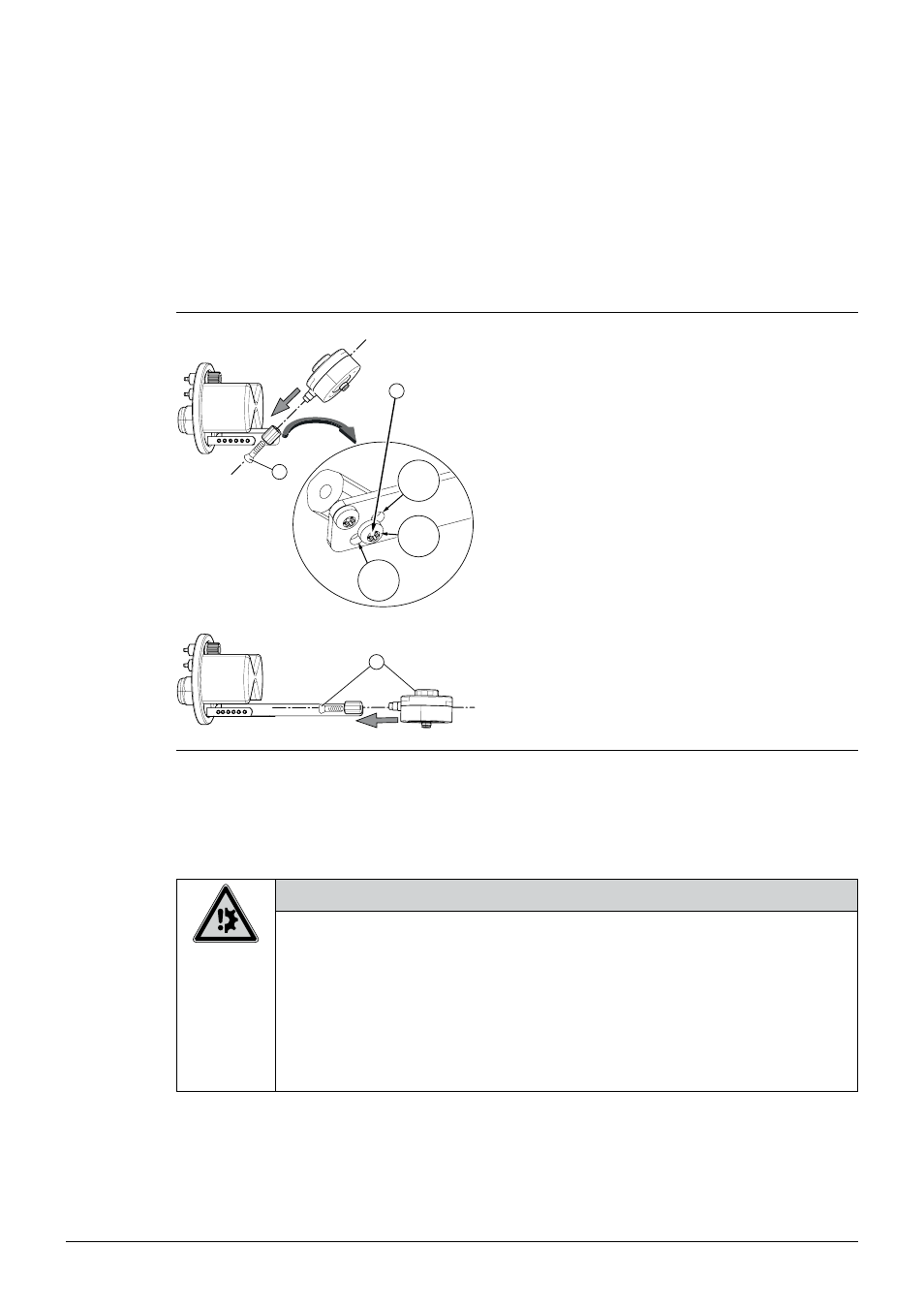

The spray head can be mounted at the spray head holder in either an angular or horizontal position.

The most appropriate position depends on the sample product and its spray drying requirements. In

all three angular positions the thermal load of the spray head is considerably decreased because the

spray head is out of the central flow of the hot drying gas. This makes the angular position an option

for spraying heat-sensitive materials.

30°

30°

30°

45°

60°

30°

30°

30°

45°

60°

1

For angular spray head position:

• To set the angulation of the spray head holder

remove the angulation screw a first. Then swivel

the spray head holder to the desired angle (30°,

45° or 60°) and reattach the screw in the chosen

angle. Fasten the screw again.

• To mount the spray head, use a small torx screw

(M3×16) to fix it at the holder b.

For vertical spray head position:

To mount the spray head in vertical position c, use a

small torx screw to fix it at the holder.

5.5

Peristaltic pump and feed tubing installation

The peristaltic pump uses a pulley drive to transport liquids through the tubing. The pump design is

dry run safe. During the spray drying process it constantly feeds the spray head with sample liquid.

Notice

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or parts of it

• Wipe off any liquids instantly

• Place the sample vessel onto the designated reservoir-plate on top of the instrument

• Ensure a safe positioning of the sample vessel

• Do not move the instrument when it is loaded with liquid

• Keep external vibrations away from the instrument